Construction method for tunnel working face counterpressure treatment during tunnel excavation

A tunnel excavation and construction method technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as difficult self-stabilization of the tunnel face, formation of debris flow, collapse, etc., and achieve the effect of improving construction quality and improving construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

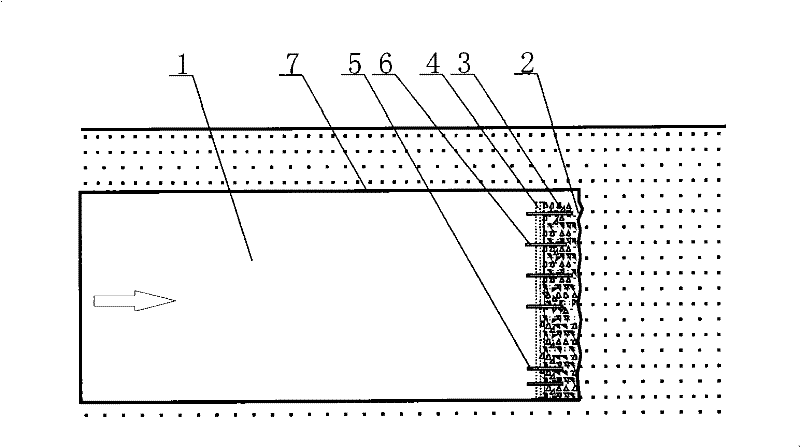

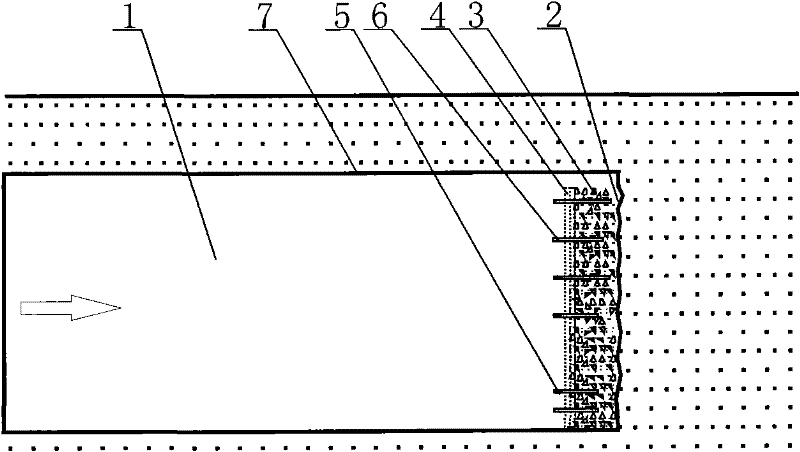

[0014] like figure 1 As shown, the construction method of tunnel face back pressure treatment in tunnel excavation is applied in the excavation process of Dahuashan Tunnel. The method includes the following steps: A. Select strongly weathered or fully weathered slag in tunnel 1 A wall 3 is piled up close to the tunnel surface 2. When the mud gushing out of the tunnel surface 2 is large, pieces of stones are added to the piled cavities, and the distance between the height of the piled wall and the vault 7 is 50cm or less, the length of the wall depends on the water gushing range of the operation face, and the length of the wall must be greater than the length of the water gushing area of the operation face. In this embodiment, since the entire operation face has water gushing phenomenon, the length of the wall is The width of the tunnel; B, spray concrete on the piled wall to form a curtain 4, and the thickness of the curtain 4 is 15cm; C, set a plurality of water guide pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com