Rotatable heat sink with internal convection

A technology of radiator and rotating ground, which is applied in the direction of indirect heat exchanger, heat exchanger type, moving pipe heat exchanger, etc., and can solve the problem of frequent service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

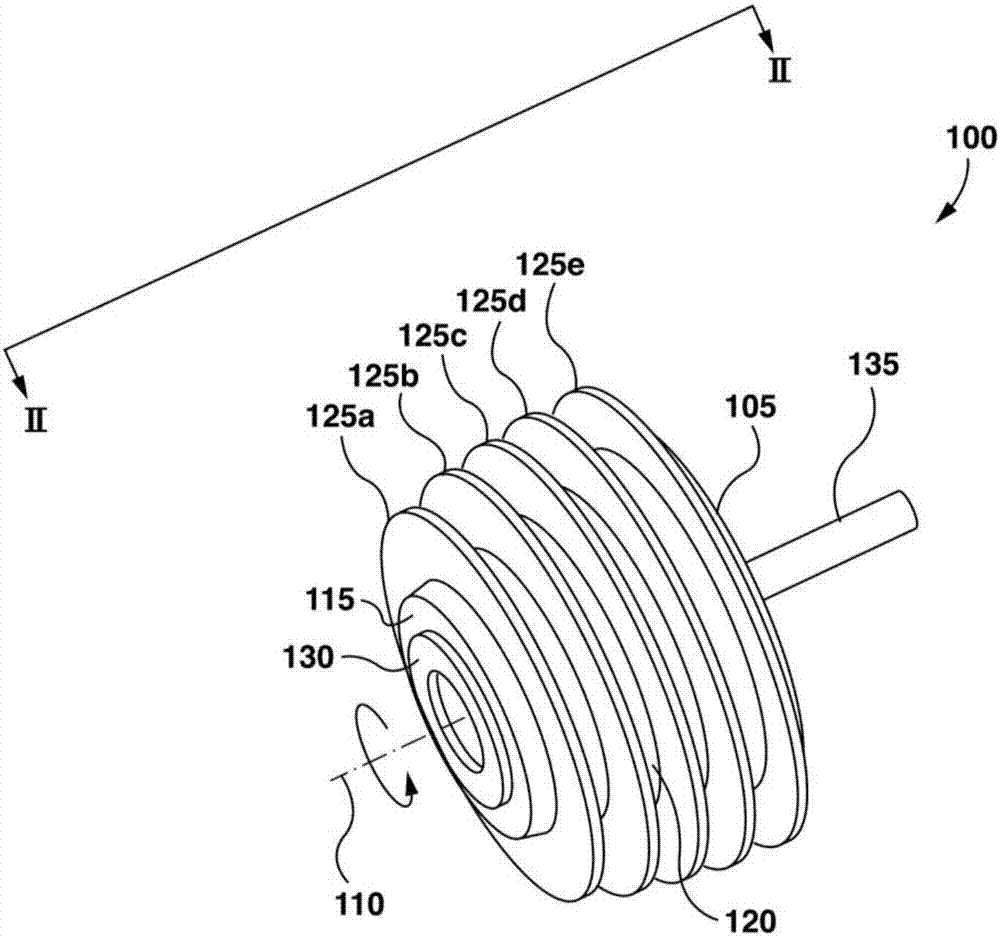

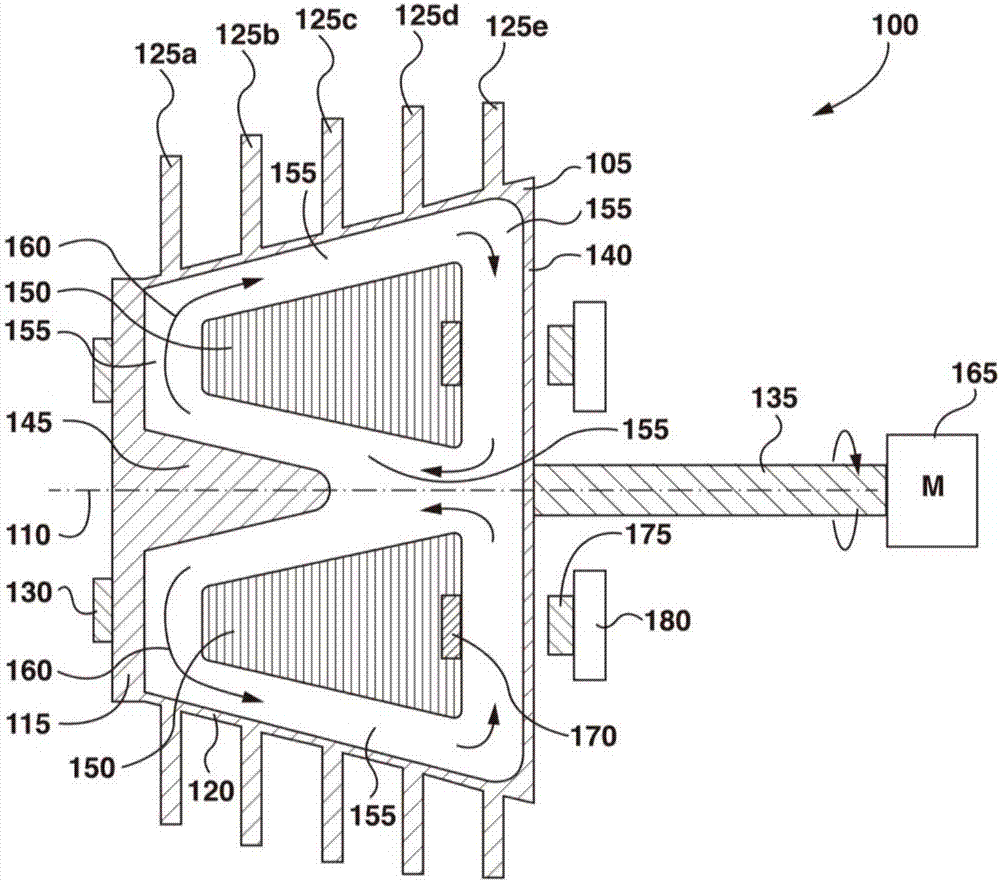

[0041] figure 1 A perspective view of a radiator arrangement 100 comprising a radiator 105 rotatable about an axis of rotation 110 is shown. The heat sink 105 includes a first end wall 115 and a second end wall (in figure 1not visible in ), both are arranged radially on the axis of rotation 110 . The heat sink 105 also includes side walls 120 that cooperate with the first end wall 115 and the second end wall to define the heat sink 105 . The radiator 105 is configured to enclose a cooling fluid. Device 100 also includes fins 125a , 125b , 125c , 125d , and 125e (collectively fins 125 ) extending radially from the outer surface of sidewall 120 . An annular layer of light wavelength converting material 130 is disposed on the outer surface of the first end wall 115 . A shaft 135 extends from the second end wall along the axis of rotation 110 . Shaft 135 may be used to couple device 100 to a source of mechanical actuation, such as an electric motor.

[0042] When the excitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com