Power battery aluminum shell with damping function and high safety

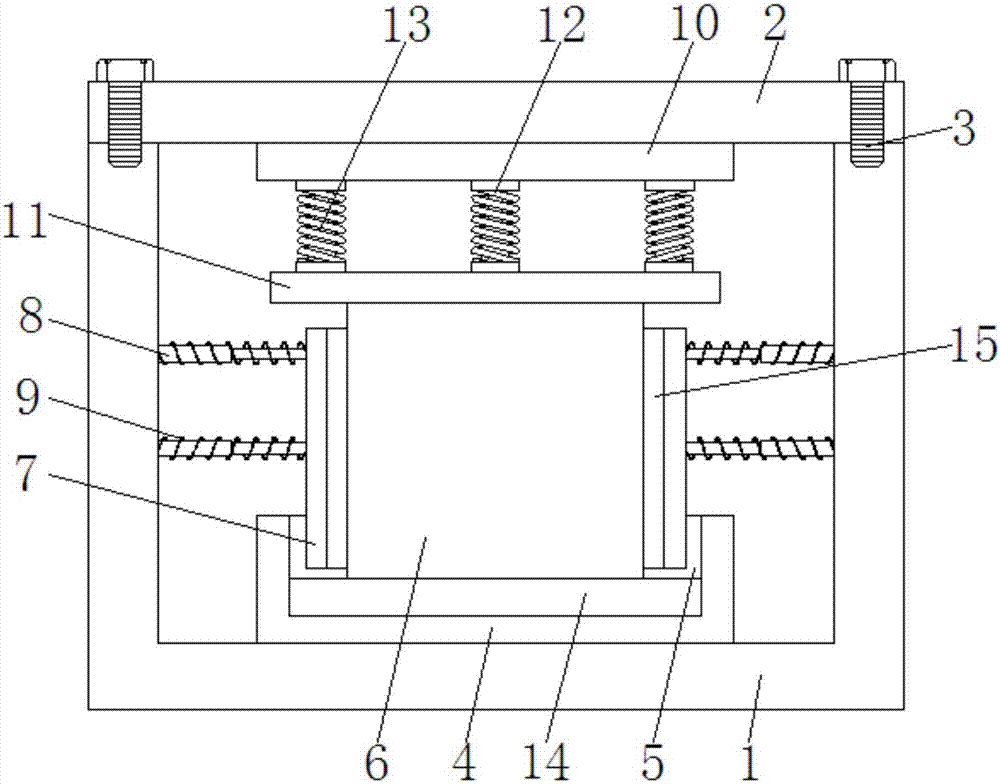

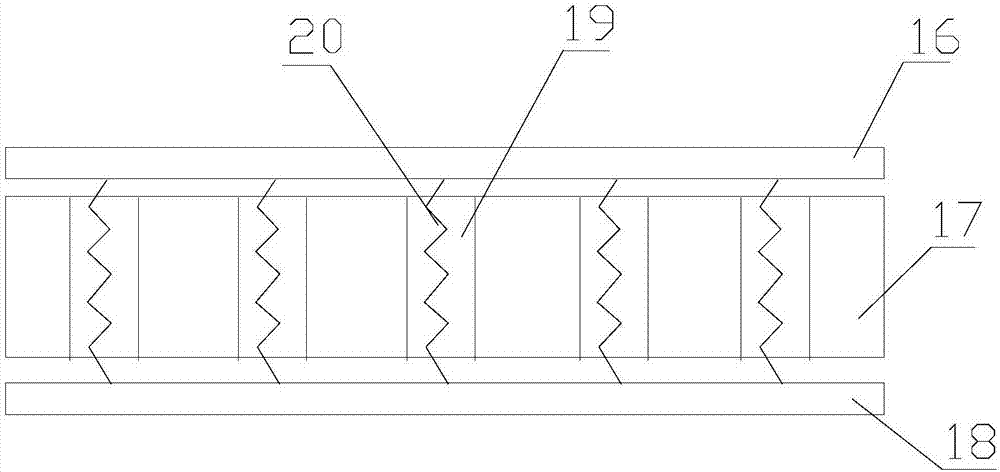

A power battery and safety technology, which is applied in the field of battery spare parts, can solve the problems of single shock absorption direction and incomplete shock absorption, and achieve the effects of complete shock absorption, buffer balance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

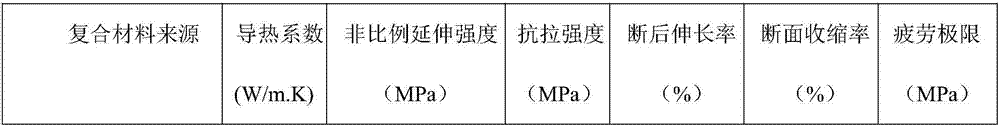

Embodiment 2

[0027] It is basically the same as Example 1, the only difference is:

[0028] The high thermal conductivity composite material is made of at least the following components by weight: 87 parts of aluminum, 0.67 parts of magnesium, 0.11 parts of manganese, 0.14 parts of iron, 0.03 parts of boron, 0.15 parts of titanium, 0.017 parts of zirconium, and 14.3 parts of silicon nitride , 1.57 parts of carbon nanotubes, 0.60 parts of nano-copper, and 0.41 parts of nano-silver;

[0029] The high elasticity and high thermal conductivity composite material is made of at least the following components by weight: 0.67 parts of carbon, 0.97 parts of manganese, 0.44 parts of chromium, 0.57 parts of nickel, 0.022 parts of phosphorus, 2.62 parts of silicon nitride, and 1.74 parts of carbon nanotubes , 0.22 parts of nano-copper, 0.14 parts of nano-silver.

Embodiment 3

[0031] It is basically the same as Example 1, the only difference is:

[0032] The high thermal conductivity composite material is made of at least the following components by weight: 83 parts of aluminum, 0.71 parts of magnesium, 0.13 parts of manganese, 0.18 parts of iron, 0.07 parts of boron, 0.11 parts of titanium, 0.013 parts of zirconium, and 13.9 parts of silicon nitride , 1.61 parts of carbon nanotubes, 0.64 parts of nano-copper, and 0.37 parts of nano-silver;

[0033] The high elasticity and high thermal conductivity composite material is made of at least the following components by weight: 0.63 parts of carbon, 0.93 parts of manganese, 0.48 parts of chromium, 0.58 parts of nickel, 0.018 parts of phosphorus, 2.58 parts of silicon nitride, and 1.70 parts of carbon nanotubes , 0.18 parts of nano-copper, and 0.11 parts of nano-silver.

Embodiment 4

[0035] It is basically the same as Example 1, the only difference is:

[0036] The high thermal conductivity composite material is made of at least the following components in parts by weight: 80 parts of aluminum, 0.75 parts of magnesium, 0.10 parts of manganese, 0.28 parts of iron, 0.03 parts of boron, 0.15 parts of titanium, 0.01 parts of zirconium, and 16.7 parts of silicon nitride , 1.43 parts of carbon nanotubes, 0.67 parts of nano-copper, and 0.48 parts of nano-silver;

[0037] The high elasticity and high thermal conductivity composite material is made of at least the following components by weight: 0.61 parts of carbon, 1.08 parts of manganese, 0.38 parts of chromium, 0.46 parts of nickel, 0.011 parts of phosphorus, 2.72 parts of silicon nitride, and 1.66 parts of carbon nanotubes , 0.25 parts of nano-copper, 0.16 parts of nano-silver.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com