Piezoelectric-driven self-charged battery diaphragm and preparation method thereof

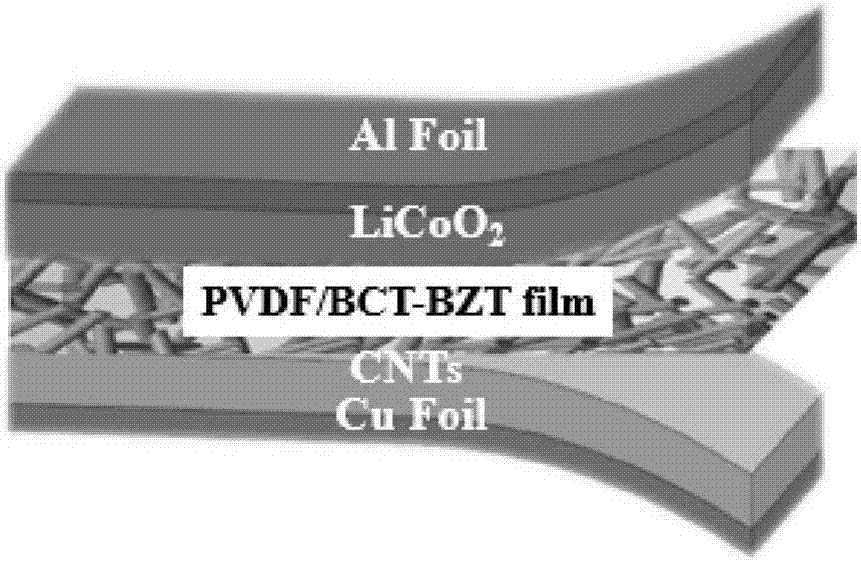

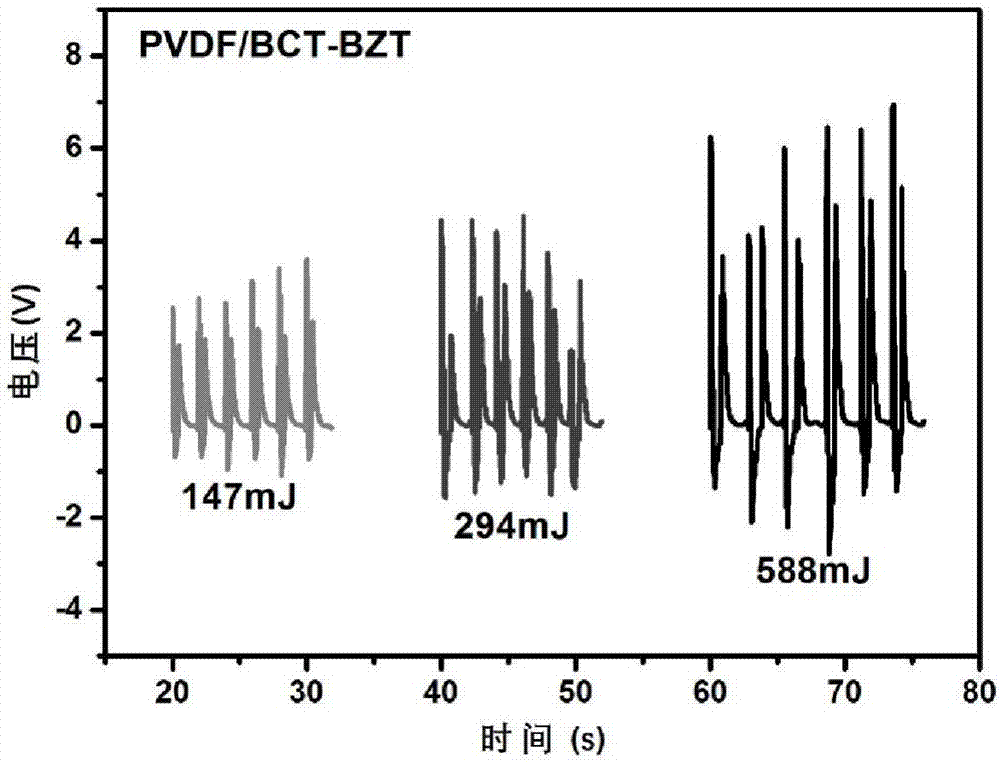

A piezoelectric drive, battery diaphragm technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of low porosity of composite films and hinder lithium ion transmission, so as to facilitate transmission and enhance piezoelectricity. Response to electric potential, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Embodiment 1: In this embodiment, the method for preparing the PVDF / BCT-BZT piezoelectric composite film used for piezoelectrically driven self-rechargeable batteries is carried out according to the following steps:

[0033] Step 1, adopt conventional sol-gel method to prepare composition and be 0.5 (Ba 0.7 Ca 0.3 ) TiO 3 -0.5Ba(Ti 0.8 Zr 0.2 )O 3 (abbreviated as BCT-BZT) sol;

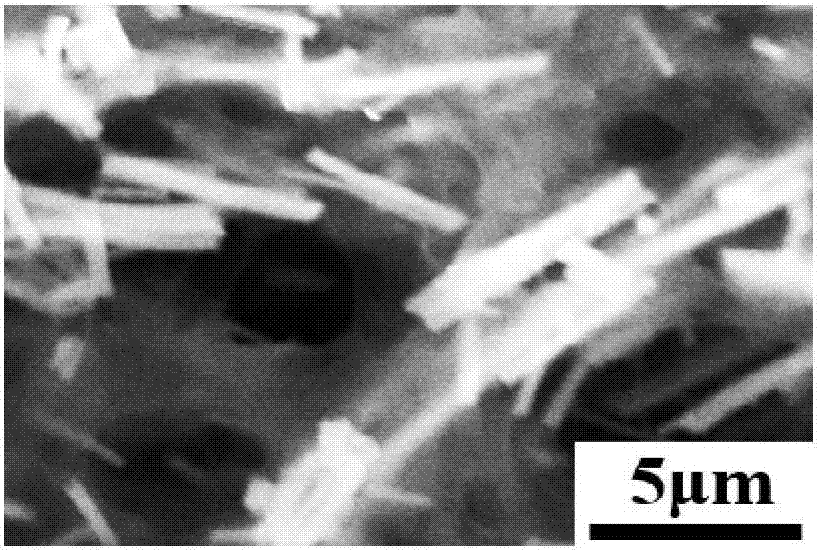

[0034] Step 2, performing electrospinning and heat treatment operations on the sol obtained in step 1 to make it a BCT-BZT piezoelectric fiber;

[0035] Step 3. Manually crush the piezoelectric fiber obtained in step 2, and then grind it for 0.5-1.5 hours, so that the length of the fiber rod is 5-6um;

[0036] Step 4, dissolve the BCT-BZT piezoelectric short fiber and PVDF powder obtained in step 3 in DMF solvent, control the mass percentage of piezoelectric material BCT-BZT in the mixed solution to 10-30%, and stir 0.5-1.5% by magnetic force h, make the solution mix uniformly;

[0037] ...

specific Embodiment approach 2

[0043] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the piezoelectric fiber is ground for 1 hour in step 3, and the others are the same as Embodiment 1.

specific Embodiment approach 3

[0044] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 4, the mass percentage of the piezoelectric material BCT-BZT in the mixed solution is controlled to be 20%. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com