Kitchen garbage treatment device

A kitchen waste and processing device technology, applied in grain processing, solid separation, filtering and screening, etc., can solve problems such as resource waste, water and air pollution, and disease infection, and achieve resource saving, efficiency improvement, and uniform material size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

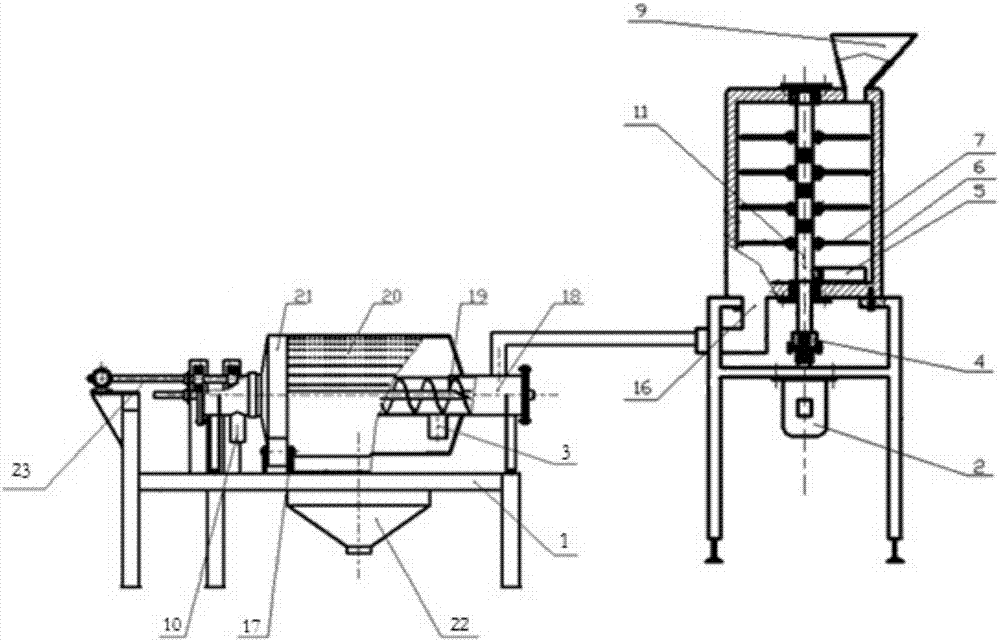

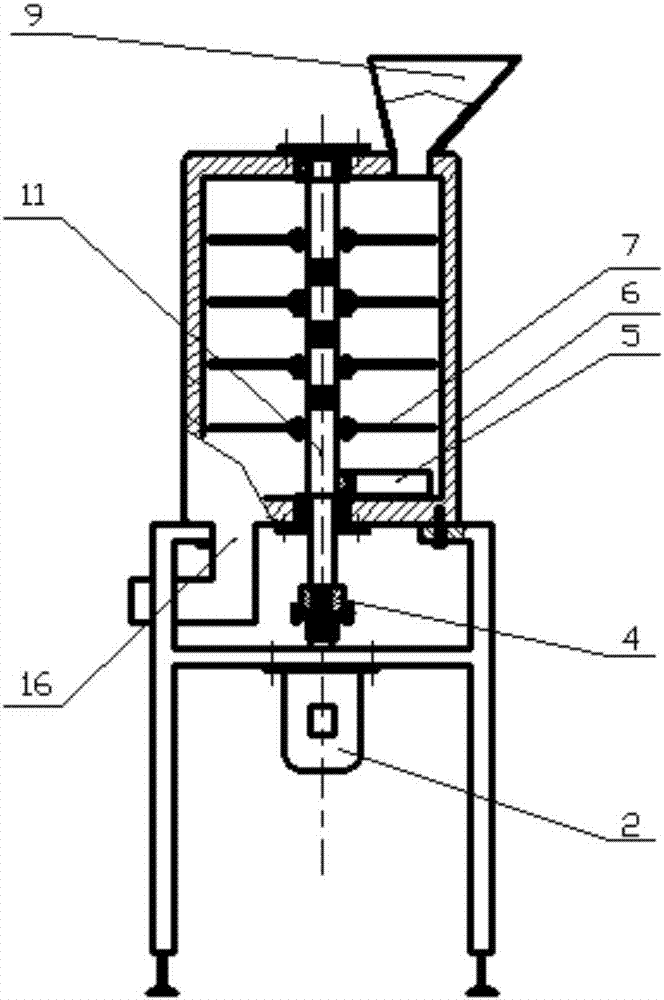

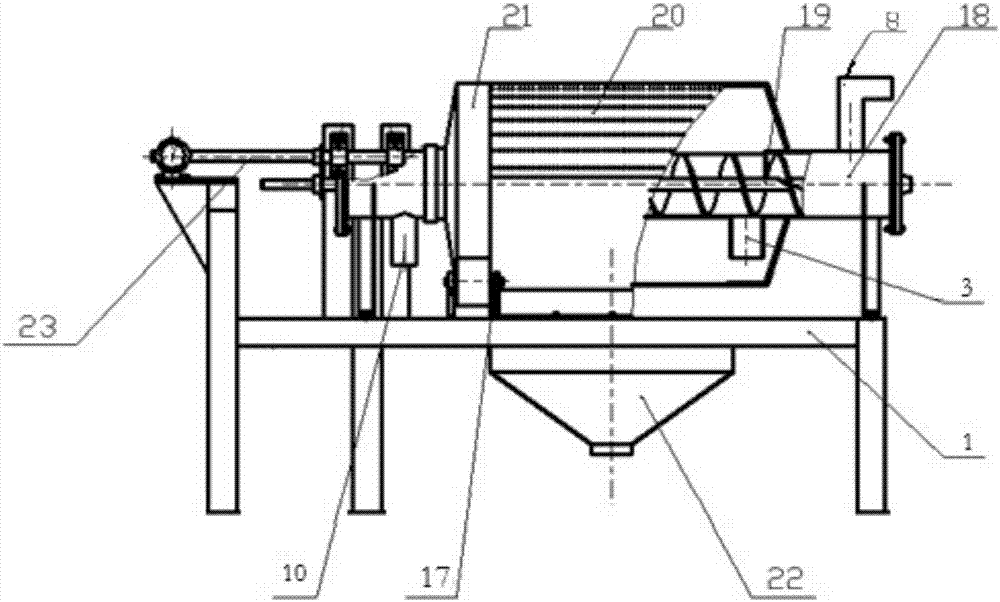

[0025] like figure 1 As shown, a kitchen waste treatment device includes a crushing system and a separation system; the crushing system includes a crushing chamber 6 and a crushing device, and the crushing chamber 6 is provided with a first discharge port 16 and a first inlet A feed port, a crushing device is provided at the first discharge port 16 and the first feed port 8 for chopping the kitchen waste in the crushing cavity 6; a feed hopper 9 is installed on the first feed port , the feed hopper 9 is an inverted cone, the purpose is to facilitate feeding. The separation system includes a cage conveyor 18 and a drum 21; the cage conveyor 18 is fixed on the mounting bracket 1, and the cage conveyor 18 is provided with a second feed port 8 and a second discharge Port 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com