Low-pressure driven shift shaft Vickers curve type low-frequency ultrasonic three-time atomization spray head

An atomizing nozzle and low-voltage drive technology, which is applied in the direction of spraying devices and liquid spraying devices, can solve the problems of small spraying angle of the nozzle, unsuitability for agricultural cultivation and ultrasonic spraying, and low spraying efficiency, so as to reduce heat generation and improve electricity consumption. Acoustic conversion efficiency and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

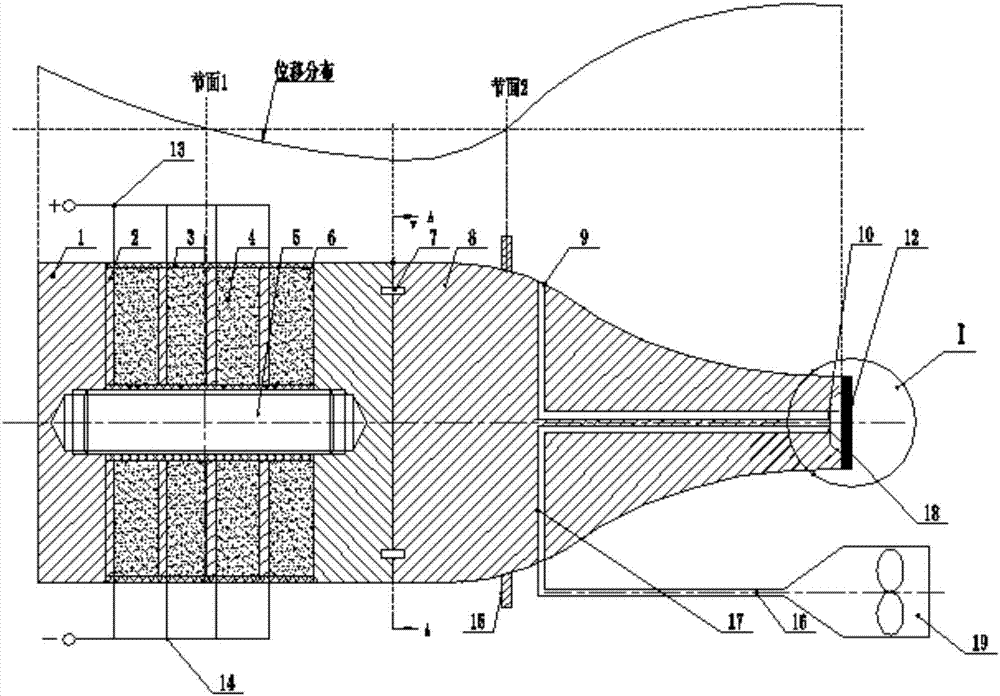

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0037] Such as figure 1 As shown, the low-voltage drive shaft-shifting Vickers curve type low-frequency ultrasonic three-time atomizing nozzle described in the present invention includes a rear cover 1, a thin electrode 2, an insulating ring 3 piezoelectric ceramics 4, and a front cover 6, all of which are fastened Bolt 5, shaft shifting Vickers curve type horn 8, metal sheet 12.

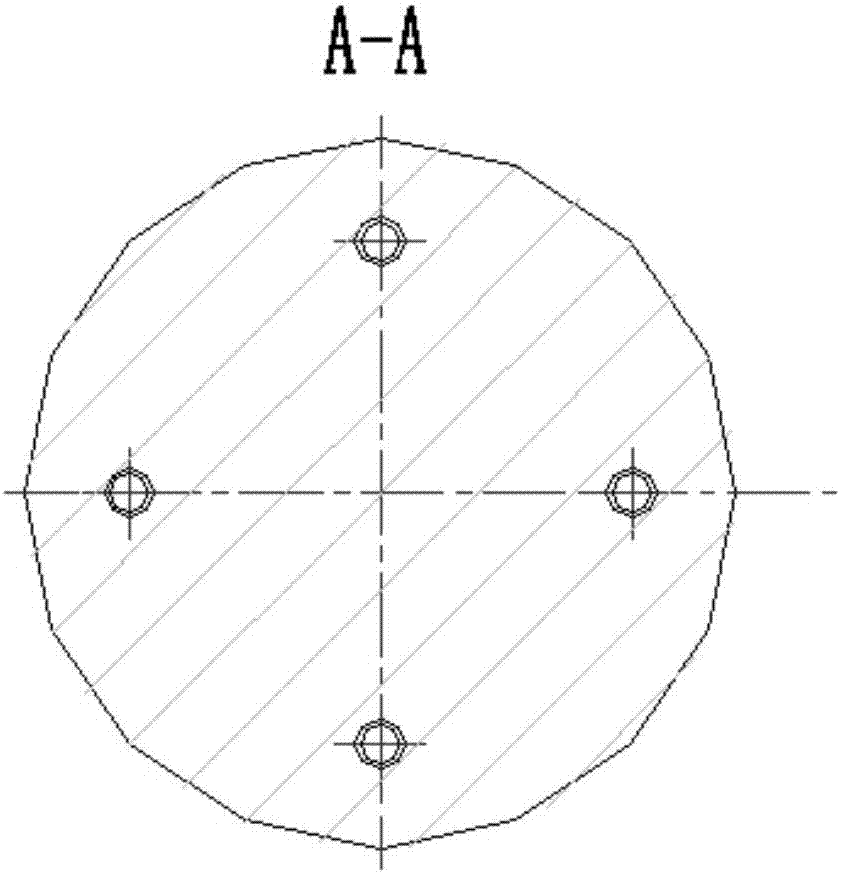

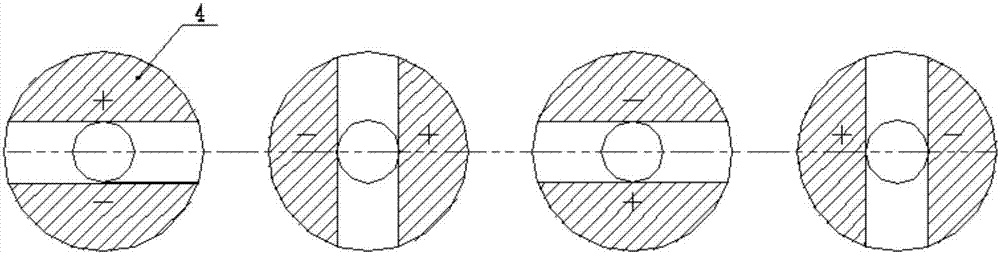

[0038] The number of thin electrodes 2 and piezoelectric ceramics 4 is four, and the thin electrodes 2 and piezoelectric ceramics 4 are arranged alternately and set on fastening bolts 5 . The rear cover plate 1 and the front cover plate 6 are respectively mounted on both ends of the fastening bolt 5, clamping the thin electrode 2 and the piezoelectric ceramic 4, and an insulating ring 3 is arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com