Rubber dynamic extrusion molding device and method

An extrusion molding and rubber technology, applied in the field of rubber processing, can solve the problems of poor rubber fluidity and difficulty in molding, and achieve the effects of decreasing flow resistance, decreasing extrusion pressure, and changing relaxation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

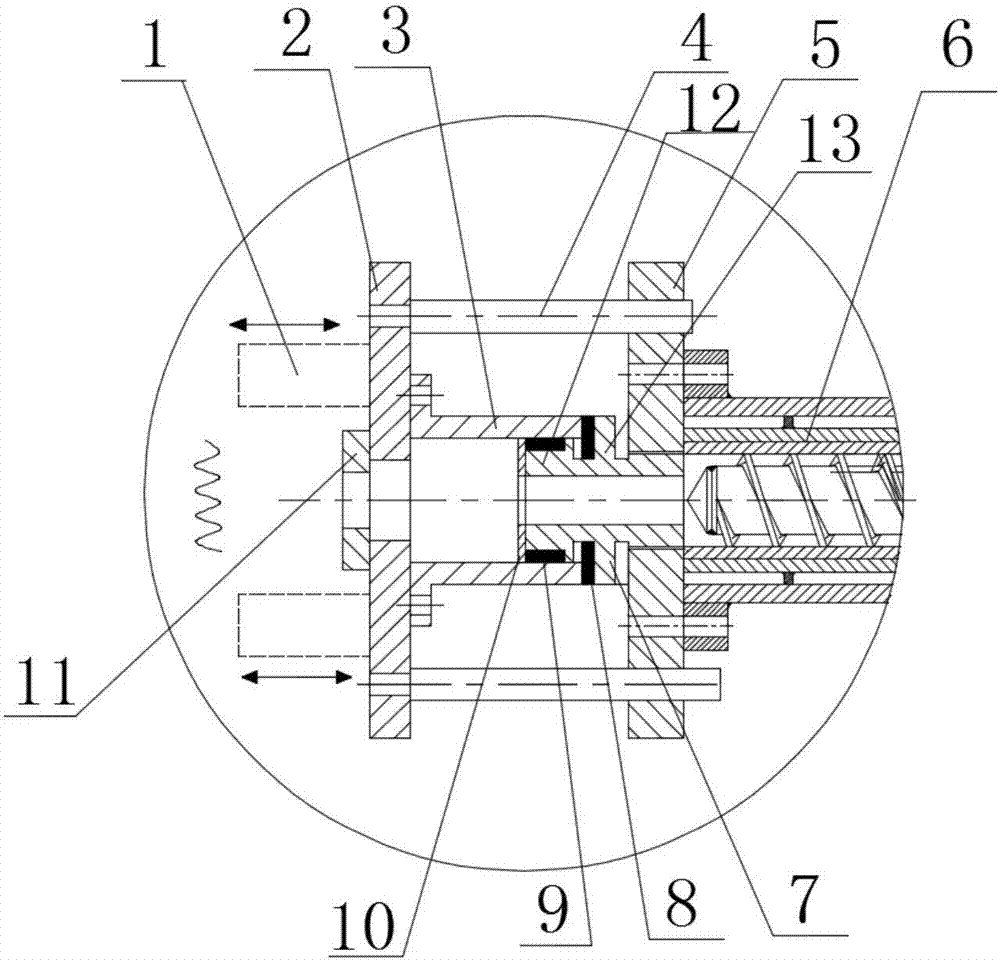

[0025]A rubber dynamic extrusion molding device, including a rubber cold feed extruder 6, a slip ring 7, a vibrating sleeve 3, a vibrating connecting plate 2, a die 11, a vibrating system 1 and a guiding mechanism 4, wherein the vibrating system 1 Connected with the vibration connection plate 2, the die 11 is fixedly installed on the vibration connection plate 2, the vibration sleeve 3 has a cavity in the middle, and a hollow channel is opened in the slip ring 7, and one end of the slip ring 7 is fed with the rubber cold through the connection ring 5 The screw extruder 6 is fixedly connected, and a first flange 12 is provided on the circumference of the other end, and a second flange 13 is provided on the outer circumference. The size of the gap is 0.03mm, the elastic ring 8 is installed on the second flange 13, the thickness of the elastic ring is 15-18mm, the elastic ring 8 is in contact with the front end face of the vibration sleeve 3, and the first flange 12 is opened Gro...

Embodiment 2

[0027] (1) 70 parts by weight of raw rubber TSR20 and 30 parts by weight of raw rubber BR9000, 2 parts by weight of raw rubber small material SAD, 4 parts by weight of ZnO and 1 part by weight of 4010NA, 40 parts by weight of carbon black N375, 25 Aromatic hydrocarbon oil in parts by weight, carbon black remaining 20 parts by weight are heated and mixed in the internal mixer to make it uniform, the heating temperature is 100-120 ° C, the mixing time is ≤ 9min, and then 1.8 parts by weight are added to the open mixer Additive S and 0.9 parts by weight of CZ, continue mixing, the total mixing time ≤ 20min, and park the mixed rubber for at least 24h;

[0028] (2) The temperature of the feeding section, plasticizing section and extrusion section of the rubber cold-feeding screw extruder is controlled at 50°C, 65°C and 75°C in sequence, the screw temperature is set at 80°C, and the head section is set at 85°C. Start the rubber cold-feed screw extruder, put the rubber compound glue ...

Embodiment 3

[0031] (1) 70 parts by weight of raw rubber TSR20 and 30 parts by weight of raw rubber BR9000, 2 parts by weight of raw rubber small material SAD, 4 parts by weight of ZnO and 1 part by weight of 4010NA, 40 parts by weight of carbon black N375, 25 Aromatic hydrocarbon oil in parts by weight, carbon black remaining 20 parts by weight are heated and mixed in the internal mixer to make it uniform, the heating temperature is 100-120 ° C, the mixing time is ≤ 9min, and then 1.8 parts by weight are added to the open mixer Additive S and 0.9 parts by weight of CZ, continue mixing, the total mixing time ≤ 20min, and park the mixed rubber for at least 24h;

[0032] (2) The temperature of the feeding section, plasticizing section and extrusion section of the rubber cold-feeding screw extruder is controlled at 50°C, 65°C and 75°C in sequence, the screw temperature is set at 80°C, and the head section is set at 85°C. Start the rubber cold-feeding screw extruder, put the rubber compound gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com