Mandrel fixing device for cold disassembly of scraper hoist and mandrel cold disassembly method

A technology of electric rake winches and fixing devices, which is applied in hoisting devices and clockwork mechanisms, etc., which can solve problems such as broken teeth, broken mandrels and tripods, and increased gas welding work, so as to prevent the rotation of the mandrel and shorten the length of the machine. Overhaul time, effect of eliminating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

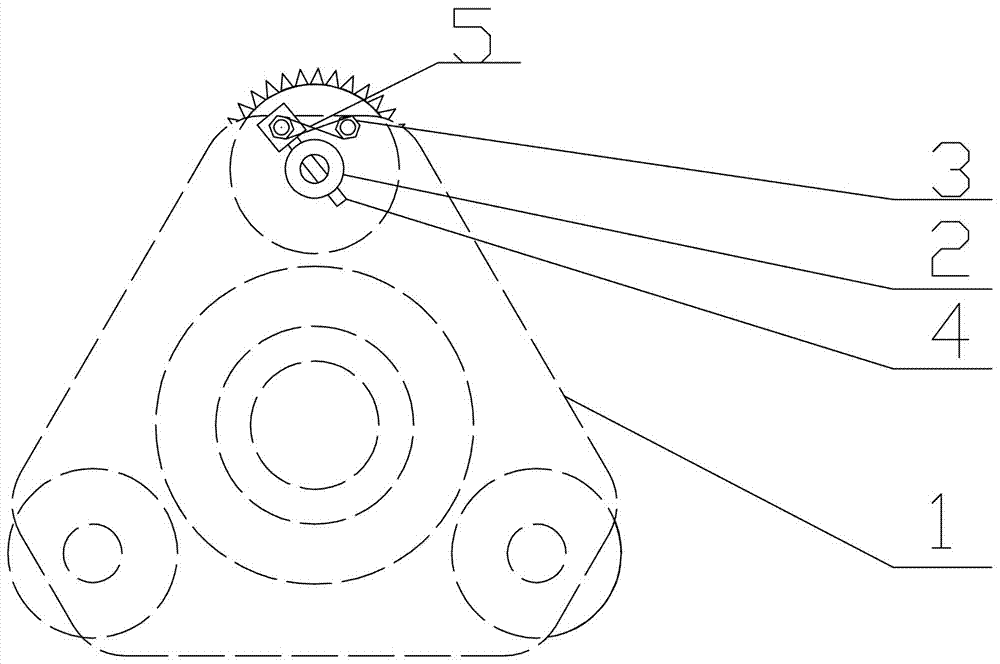

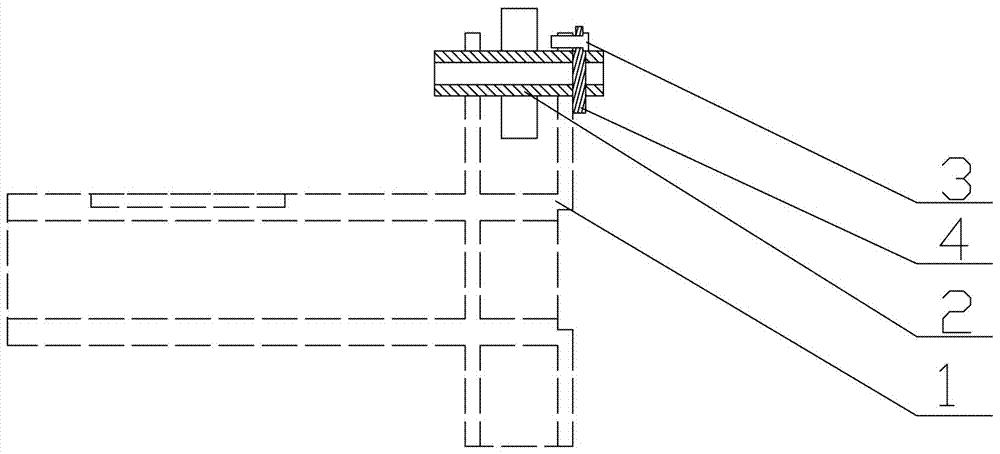

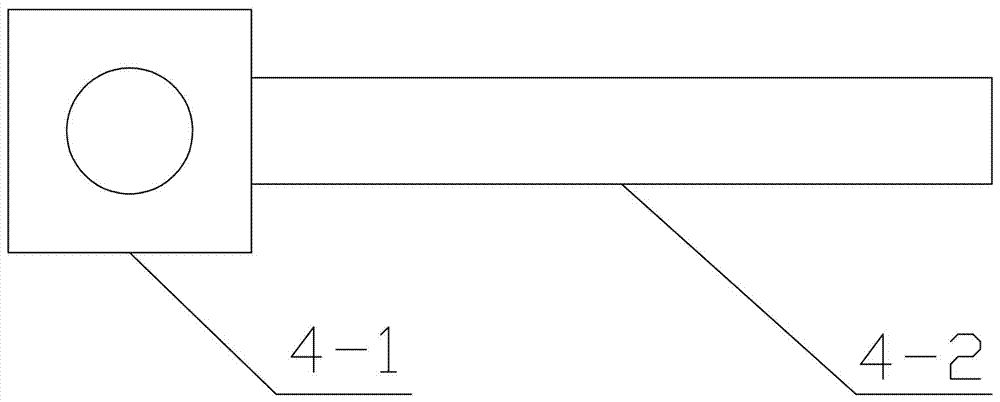

[0033] Such as Figure 1-10 As shown, the mandrel fixing device for the cold disassembly of the electric rake winch of the present invention includes a tripod 1, and two fixing bolts 3 arranged on the top of the tripod 1 are characterized in that one fixing bolt 3 is provided with a mandrel fixing pin 4. A fixed steel wire 5 is connected between the two fixed bolts 3. The mandrel fixed pin 4 includes a fixed end 4-1 and a cylindrical pin 4-2. The fixed end 4-1 is sleeved on the On the one fixing bolt 3, the cylindrical pin 4-2 is inserted into the opening at the end of the mandrel 2.

[0034] The fixed end 4-1 of the mandrel fixed pin 4 is a square fixed end, and the center of the square fixed end is provided with a central hole matching the fixed bolt 3, and the fixed bolt 3 is arranged in the center inside the hole.

[0035] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com