Method for extracting collagen from giant salamander

A collagen and giant salamander technology, applied in the biological field, can solve the problems of affecting application value, waste of resources, low purification rate and purity of collagen, and achieve the effect of improving market application value, extraction rate and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

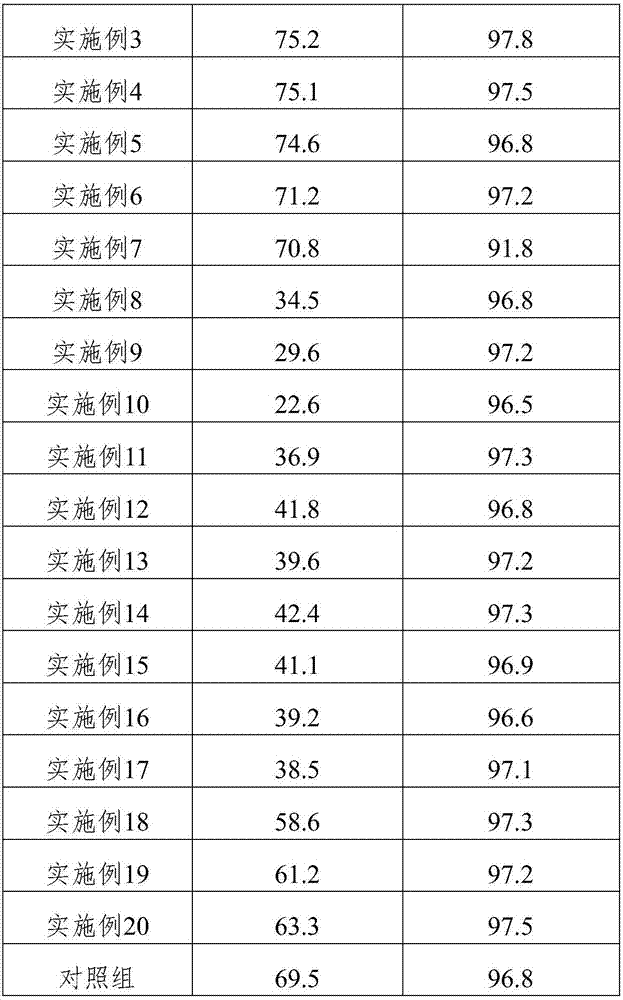

Examples

Embodiment 1

[0029] A method for extracting collagen from giant salamanders, comprising the following steps:

[0030] (1) Sterilization treatment: After the giant salamander raw material is pretreated, add 0.8 times the amount of sterilizing solution of the giant salamander raw material quality, adjust the temperature of the magnetic stirrer to 36 ° C, stir for 40 minutes, filter, and wash the filter residue with deionized water for 3 to 5 minutes. Second-rate;

[0031] The giant salamander raw material is mixed with giant salamander skin, giant salamander muscle and giant salamander bone in a mass ratio of 1:0.2:0.4;

[0032] The pretreatment is to remove impurities from the giant salamander raw material, dry and pulverize it, mix it with n-hexane and sterolase at a mass ratio of 1.8:0.3:0.1, add deionized water, and blend into a solution with a content of 50%. Heat to 38°C, stir for 100 minutes, and filter to get the filter residue;

[0033] The sterilizing solution is to mix dandelion...

Embodiment 2

[0045] A method for extracting collagen from giant salamanders, comprising the following steps:

[0046] (1) Sterilization treatment: After the giant salamander raw material is pretreated, add 1.2 times the sterilizing solution of the giant salamander raw material quality, adjust the temperature of the magnetic stirrer to 38°C, stir for 50 minutes, filter, and wash the filter residue with deionized water for 3 to 5 minutes. Second-rate;

[0047] The giant salamander raw material is mixed with giant salamander skin, giant salamander muscle and giant salamander bone in a mass ratio of 1:0.3:0.5;

[0048] The pretreatment is to remove impurities from the giant salamander raw material, dry and pulverize it, mix it with n-hexane and sterolase at a mass ratio of 2.2:0.5:0.2, add deionized water, and blend it into a solution with a content of 60%. Heat to 42°C, stir for 120 minutes, and filter to get the filter residue;

[0049] The sterilizing solution is to mix dandelion and worm...

Embodiment 3

[0061] A method for extracting collagen from giant salamanders, comprising the following steps:

[0062] (1) Sterilization treatment: After the giant salamander raw material is pretreated, add a sterilizing solution of 1 times the mass of the giant salamander raw material, adjust the temperature of the magnetic stirrer to 37°C, stir for 45 minutes, filter, and wash the filter residue with deionized water for 3 to 5 minutes. Second-rate;

[0063] The giant salamander raw material is mixed with giant salamander skin, giant salamander muscle and giant salamander bone in a mass ratio of 1:0.25:0.45;

[0064] The pretreatment is to remove impurities from the giant salamander raw material, dry and pulverize it, mix it with n-hexane and sterolase at a mass ratio of 2:0.4:0.15, add deionized water, and blend it into a solution with a content of 55%. Heat to 40°C, stir for 110 minutes, and filter to get the filter residue;

[0065] The sterilizing solution is to mix dandelion and wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com