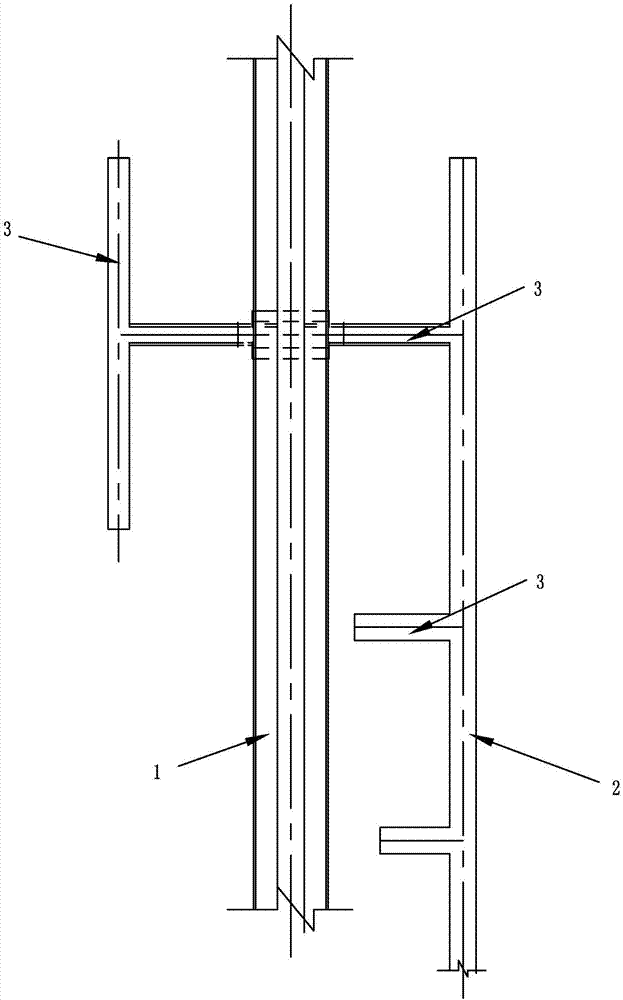

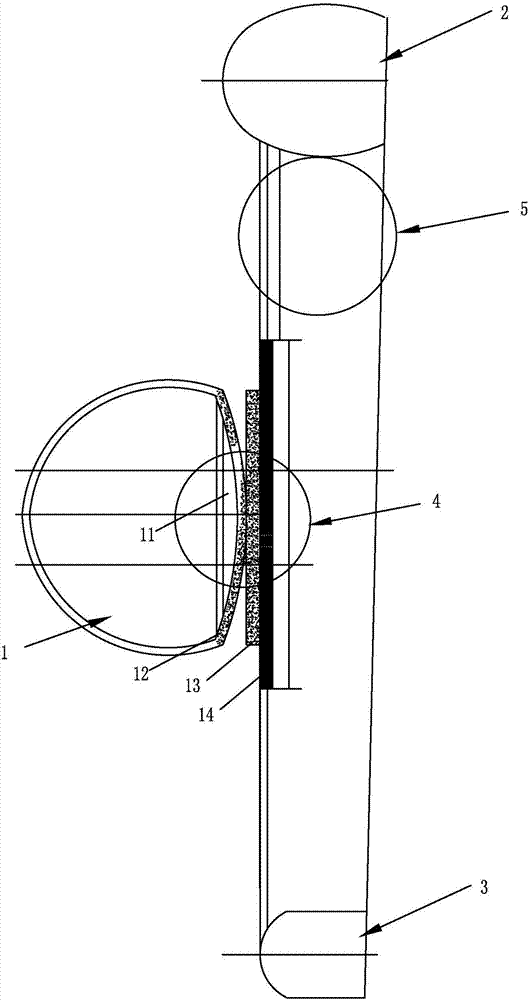

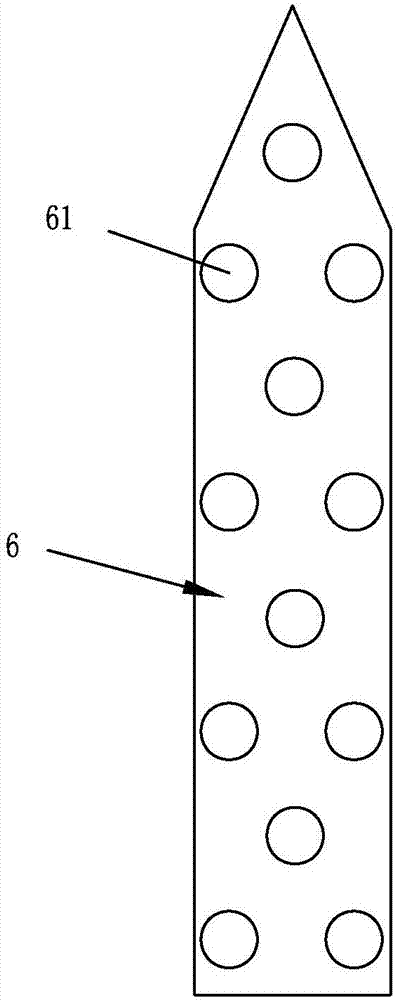

Fine cross-over tunnel vibration-reducing blasting construction method

A construction method and sophisticated technology, applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problem of less access to the tunnel at upper and lower intersections, and achieve the effects of less safety risk, easy quality assurance, and short construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific location of this embodiment is the small alpine tunnel from Kunming to Changsha. The starting and ending pile numbers of this small alpine tunnel are: DK565+060~DK567+917, with a total length of 2857m. It is a single-hole and double-track structure tunnel with a designed longitudinal slope of -25‰. The Xiaoalaoshan Tunnel is located in the middle and low mountainous area of the erosion structure of the Yunnan-Guizhou Plateau. The terrain in the area is generally high in the east and low in the west. The highest point in the tunnel site area is located at the top of the mountain on the south side of the tunnel axis, with an altitude of 1054.9m, and the lowest point is located at the river ditch on the side of the tunnel exit. Center, with an altitude of 677.5m and a relative height difference of 377.4m. The area through which the tunnel body passes is mainly characterized by the widespread distribution of carbonate rocks, and has the landform characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com