Concentration and particle size measurement system of dust particles of coal mine

A dust particle and measurement system technology, which is applied in the direction of measurement devices, particle size analysis, particle suspension analysis, etc., can solve the problems of complicated operation, low reliability, and slow measurement speed, and achieve improved response sensitivity, fast real-time measurement, and high automation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

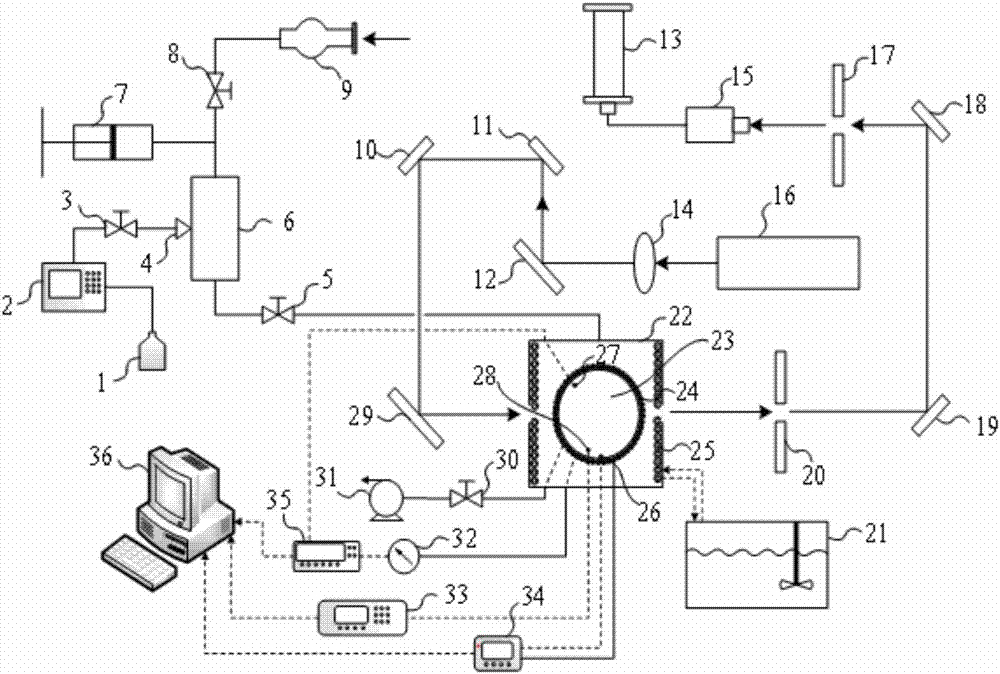

[0023] The invention discloses a coal mine dust particle concentration and particle size measurement system, which is composed of a sample collection system, an optical system, a humidity control system, and a temperature and pressure control test system.

[0024] The sample collection system includes: a second valve 5 , a sample collector 6 , a manual pump 7 , a third valve 8 , a drying tube 9 , a sample pool 23 , a fourth valve 30 , and a vacuum pump 31 .

[0025] Close the second valve 5 and the third valve 8, open the vacuum pump 31 and open the fourth valve 30 to vacuumize the sample pool 23, close the fourth valve 30 and open the third valve 8 at the same time, the dusty gas passes through the drying pipe 9 to dry, open After the second valve 5 enters the sample collector 6 , the second valve 5 is closed, and the hand pump 7 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com