Plant and method for recovering metals and/or metal oxides from industrial process waste, in particular refinery waste

An industrial process, oxide technology, applied in lighting and heating equipment, solid waste removal, combustion methods, etc., can solve the problems of difficult recovery and separation, expensive, difficult separation in the recovery process, and achieve the effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

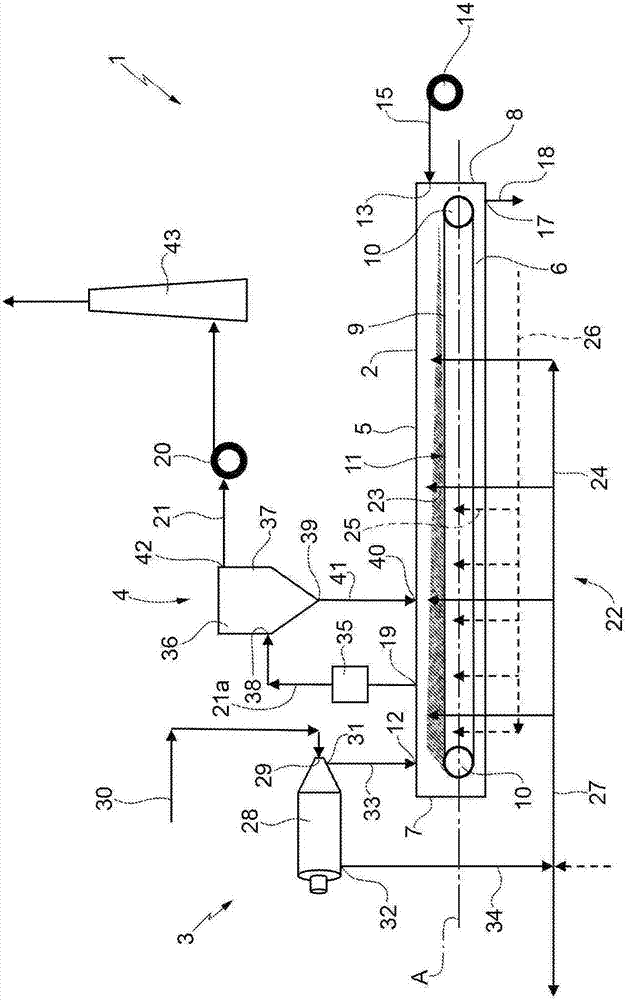

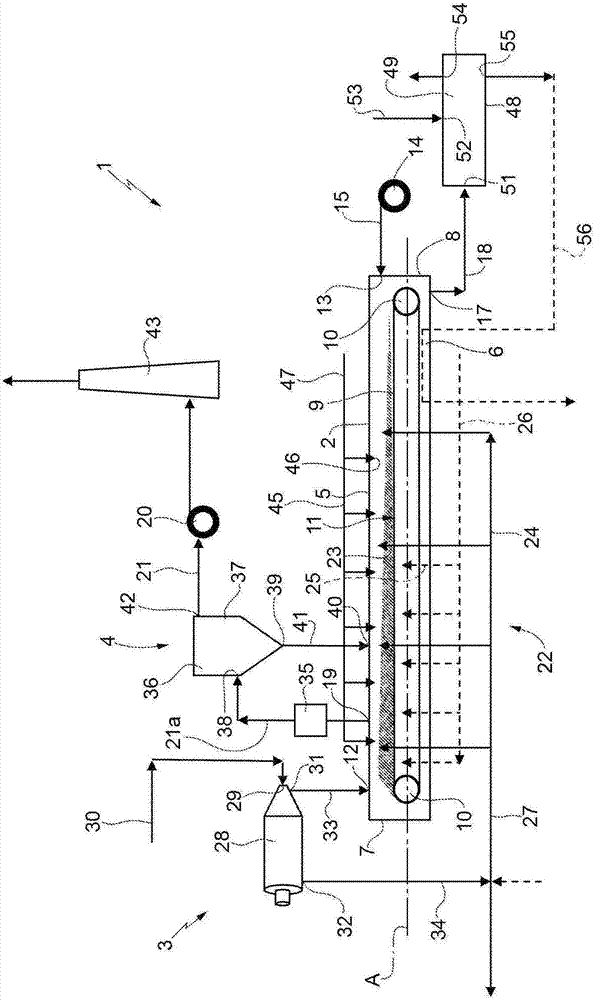

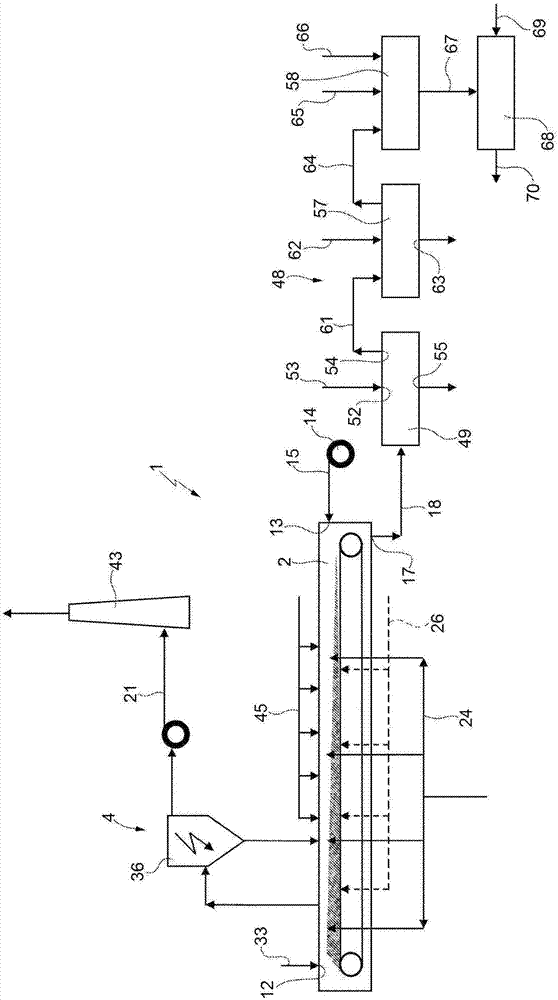

[0040] figure 1 A plant and a method for recovering metals and / or metal oxides from industrial process wastes, in particular wastes generated when refining oil products (refinery wastes), are shown in schematic form.

[0041] For example, the waste material to be treated in the plant 1 is ash produced by the gasification process and contains in particular nickel oxide, vanadium and molybdenum.

[0042] exist figure 1 In an embodiment of the present invention, the plant 1 makes it possible to recover from industrial waste a solid phase rich in metals, mainly in the form of oxides; said oxides can then be fed to a subsequent metal separation step (hereinafter by way of example describe).

[0043] The plant 1 mainly comprises a belt conveyor furnace 2, a pretreatment unit 3 located upstream of the belt conveyor furnace 2 along the path of the waste material to be treated, and receiving and processing the flue gas generated in the belt conveyor furnace 2 The flue gas treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com