Method for producing molten iron using electric furnace

A technology of molten iron and electric furnace, applied in the direction of electric furnace, furnace, charge control, etc., can solve the problem of the distance change between the auxiliary burner and iron scrap, achieve efficient heating or melting, reduce power consumption, and shorten the operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

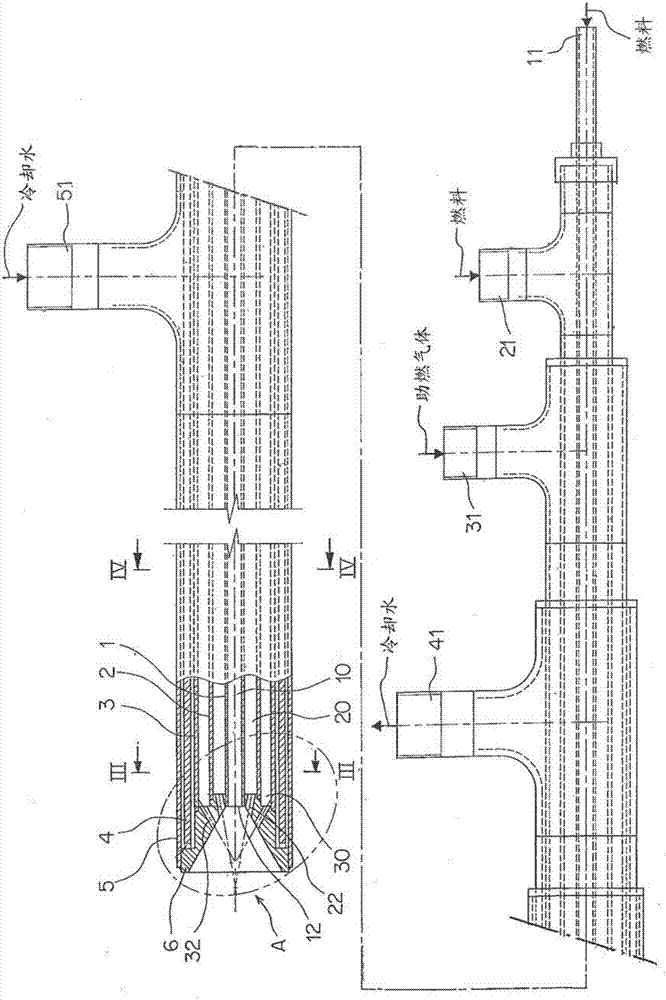

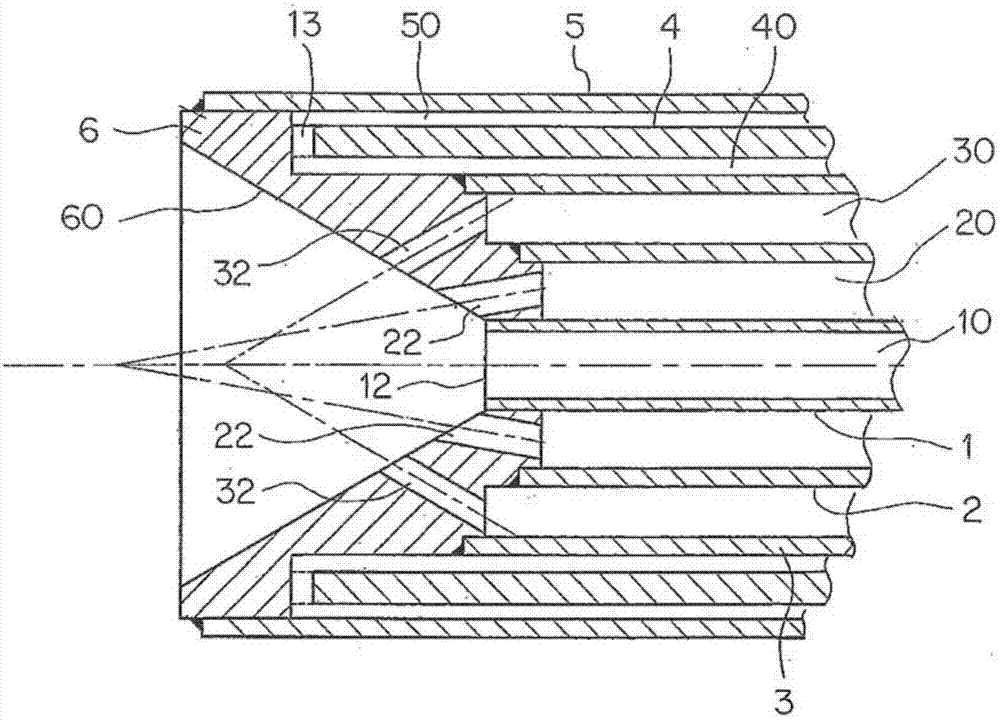

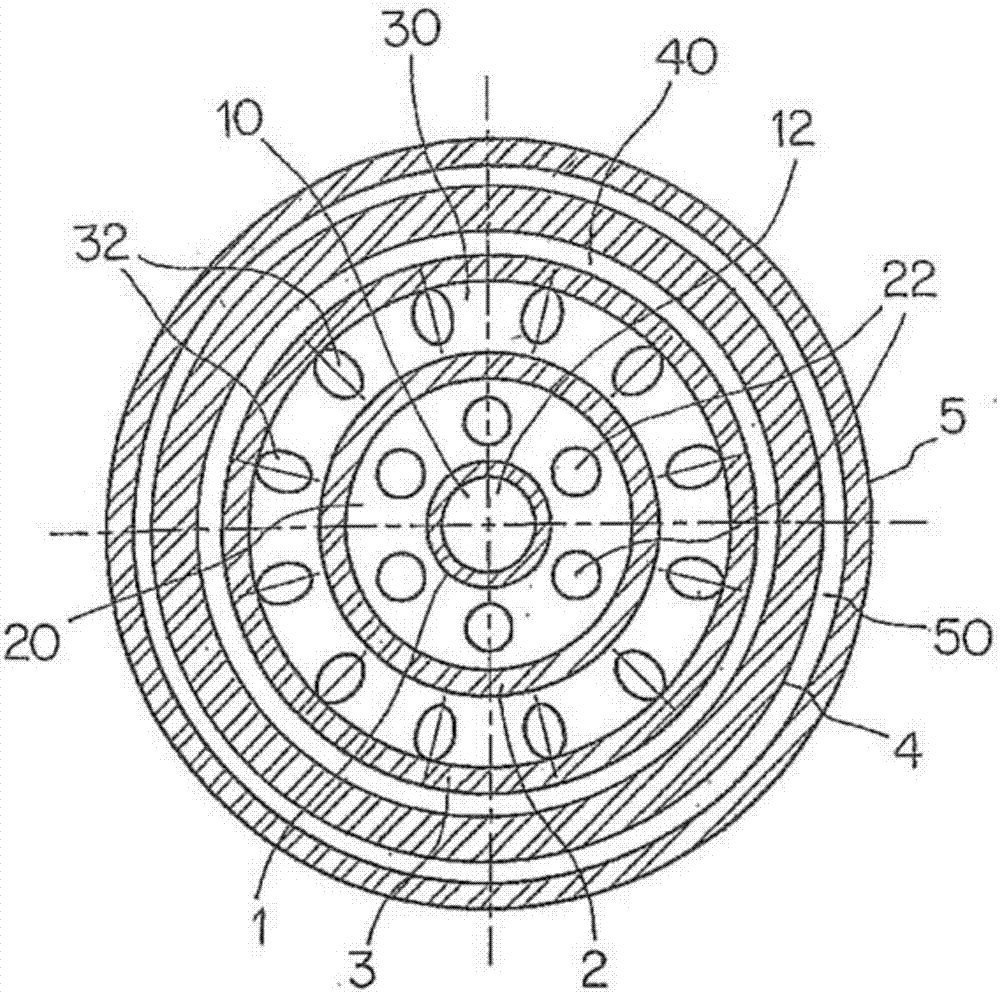

[0065] exist Figure 1 ~ Figure 4 In the auxiliary burner of the structure shown, the flame temperature of the burner was measured using two kinds of fuels having different ignition temperatures. The output of the burner is 30 Mcal / h.

[0066]As fuel, LPG (gas fuel) and fine powder carbon (solid fuel) are used. As fine powder carbon, lignite with a calorific value of 6200kcal / kg and a particle size of d(90)=100μm is used, and the flow rate of nitrogen gas for fine powder carbon transportation is 1.2Nm 3 / h.

[0067] In the test, the solid fuel ratio was set to 10% and 50%, and the flame temperatures at 0.2 m and 0.4 m from the front end of the burner were measured using an optical fiber thermometer and an R-type thermocouple.

[0068] Express the relationship between the proportion of solid fuel in the fuel and the flame temperature in Figure 6 middle. Under the condition that the gas fuel (LPG) ratio was high, the flame temperature at the position of 0.2 m near the burn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com