System for confining and cooling melt from the core of a water cooled-water modified reactor

A core melt and closed system technology, applied in the field of nuclear power, to achieve the effect of improving structural reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

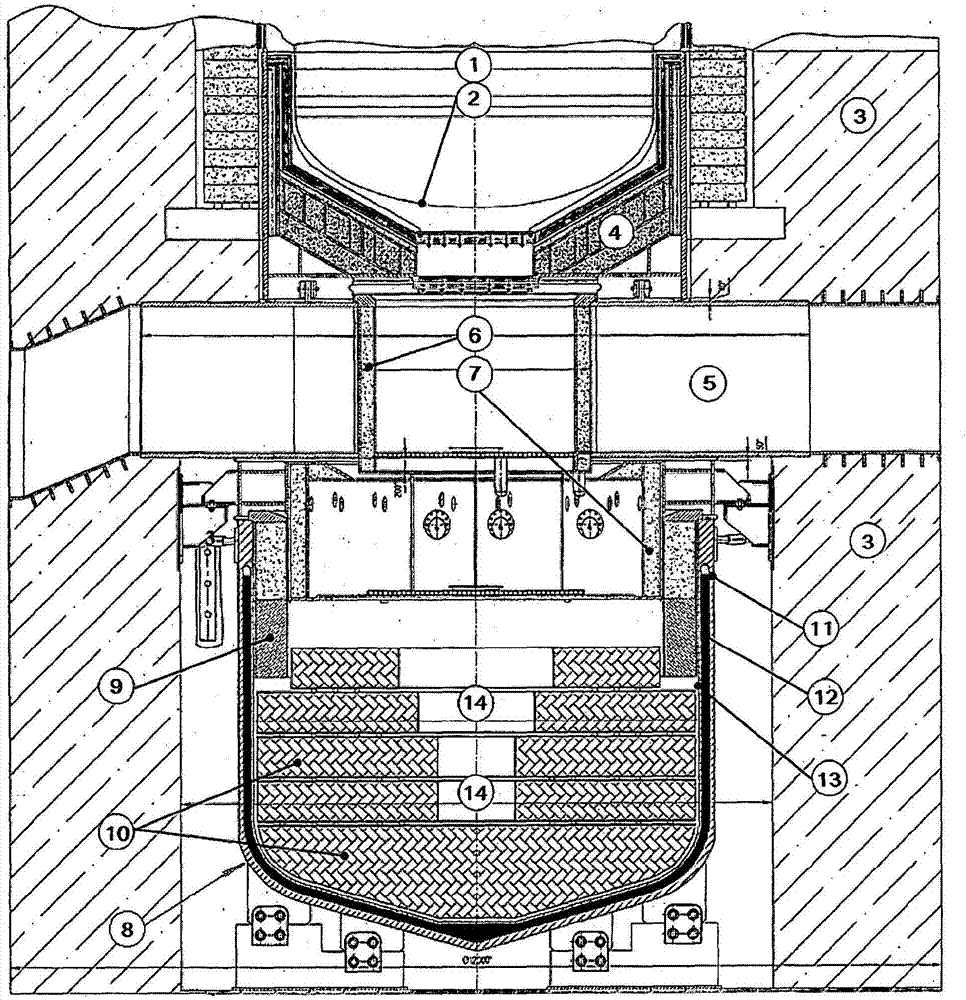

[0052] According to the claimed invention, a conical deflector (4) supported by a cantilever truss (5) with a thermal shield (6) is installed at the bottom of the reactor vessel (1) in a concrete dome (3) ( 2) Below.

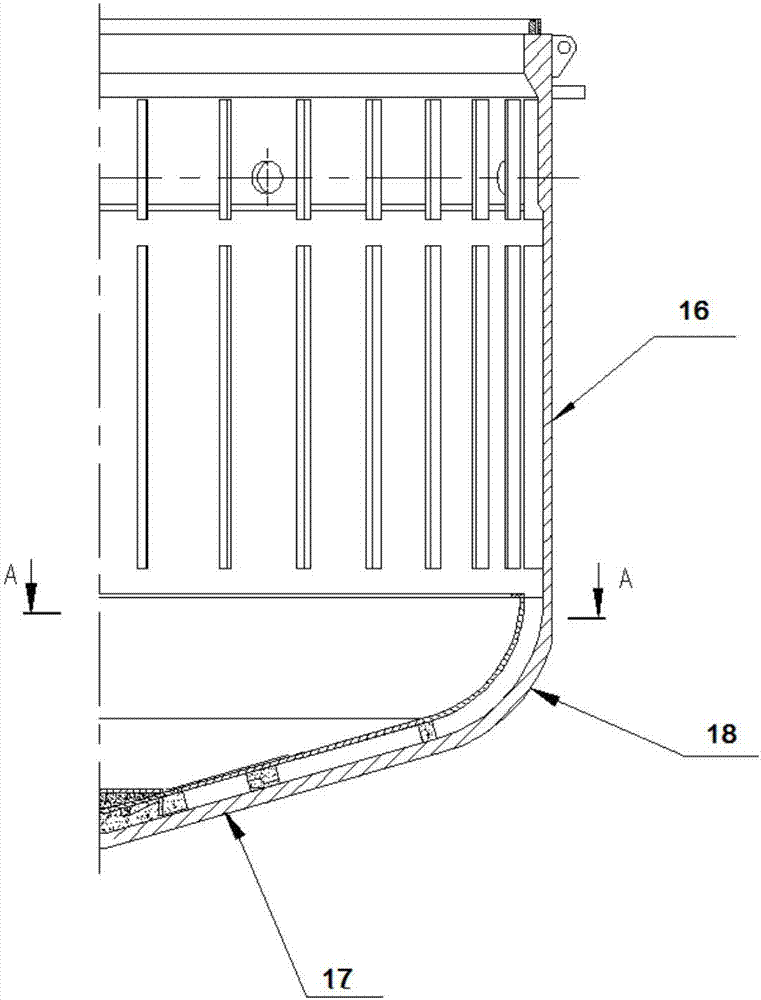

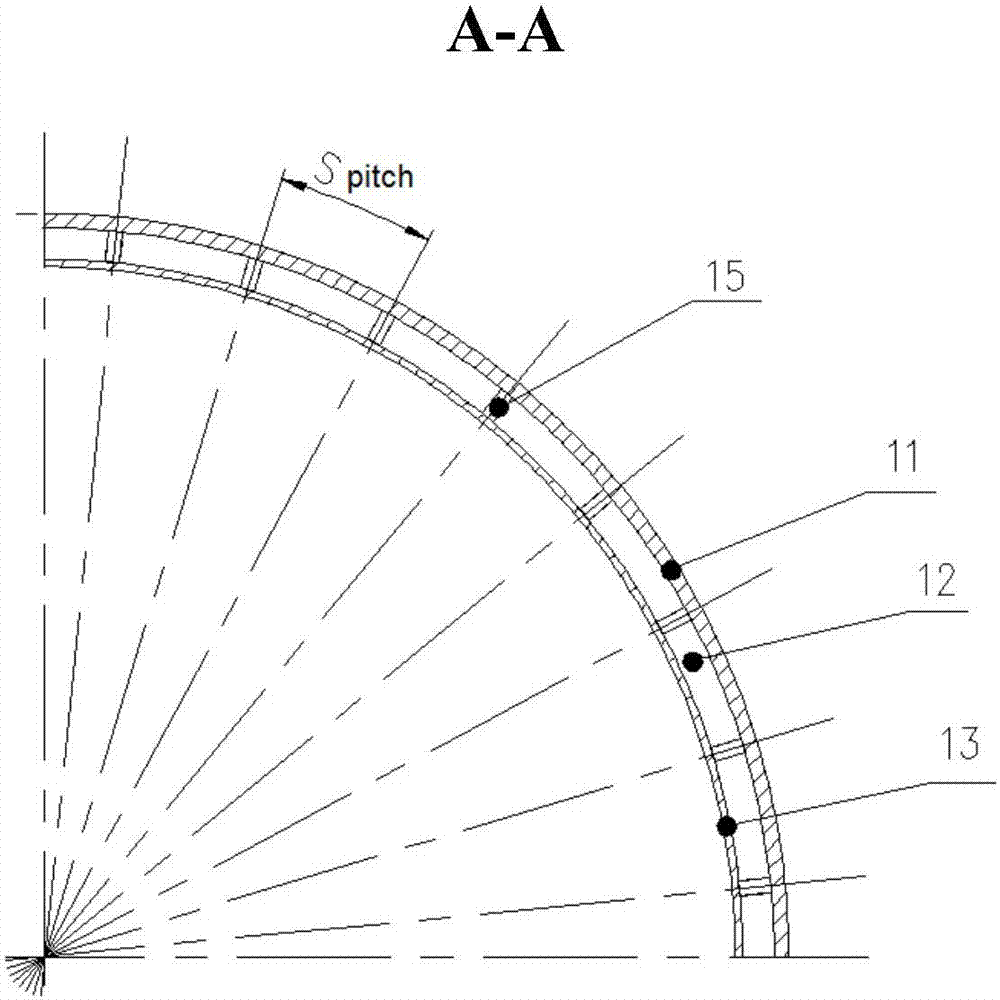

[0053] Below the cantilever truss (5) there is a core capture device (8) with a cooling cladding (vessel) in the form of a multi-layered vessel, comprising an outer metal layer (11) and an inner metal layer ( 13) (Wall) having a non-metallic filler (12) between said metallic outer layer and said metallic inner layer. Inside the core capture device (8) there is a sacrificial filler material (10) applied to dilute the core melt. In addition, the packing (11) is equipped with stepped conical or cylindrical pockets (14) for containing the core melt.

[0054] Furthermore, the core capture device vessel (8) is provided with a thermal protection layer (9) of the multilayer vessel flange.

[0055] The console (7) is located in the space between the cantilever truss (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com