Novel zinc-based infrared coating

A zinc-based infrared and coating technology, applied in radiation-absorbing coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex preparation process of infrared coatings, and achieve low cost, wide application space and low raw material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

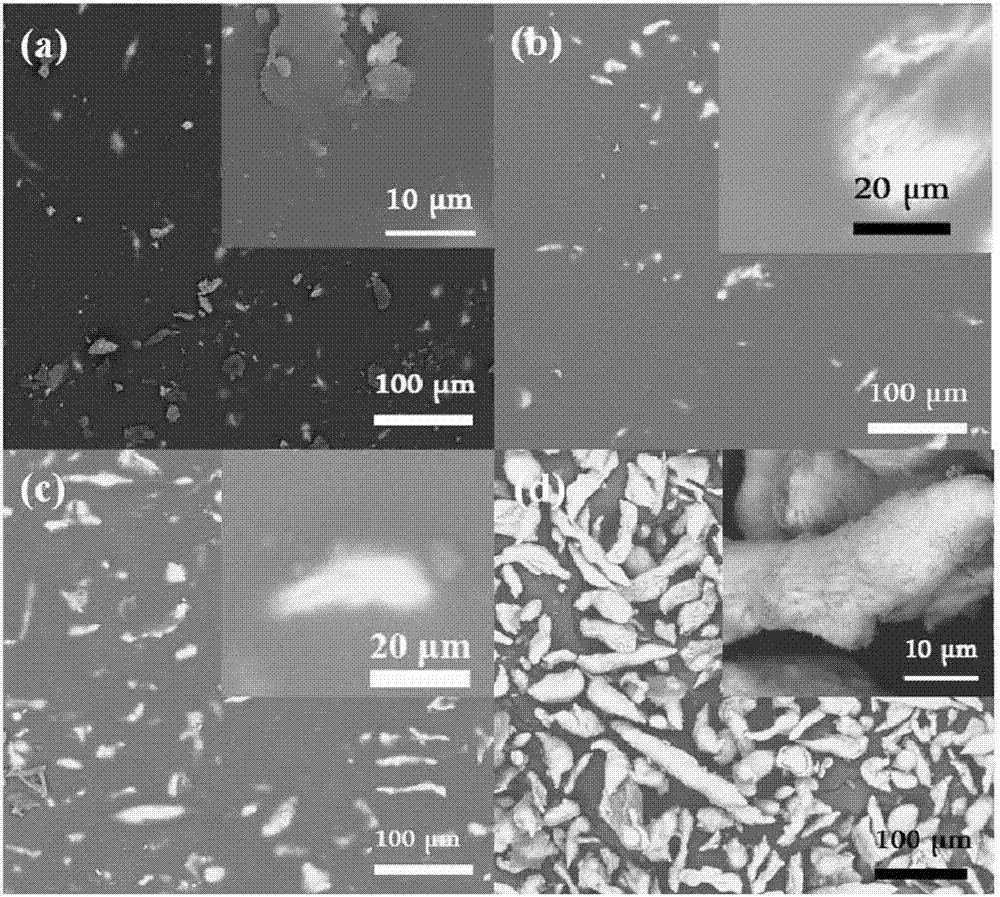

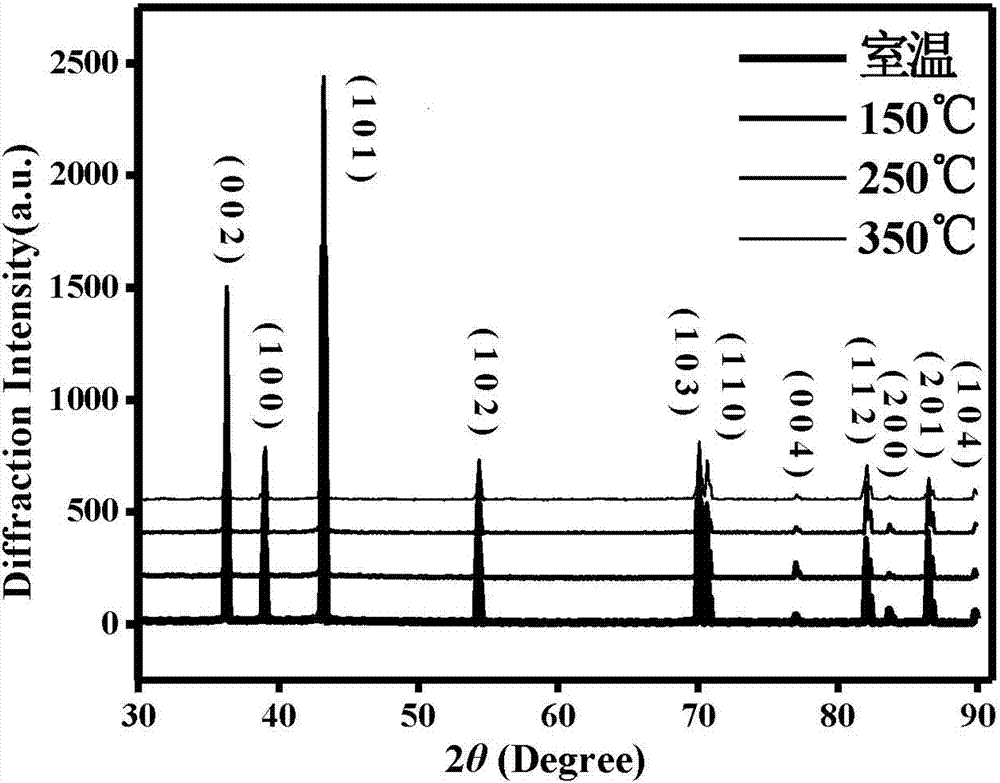

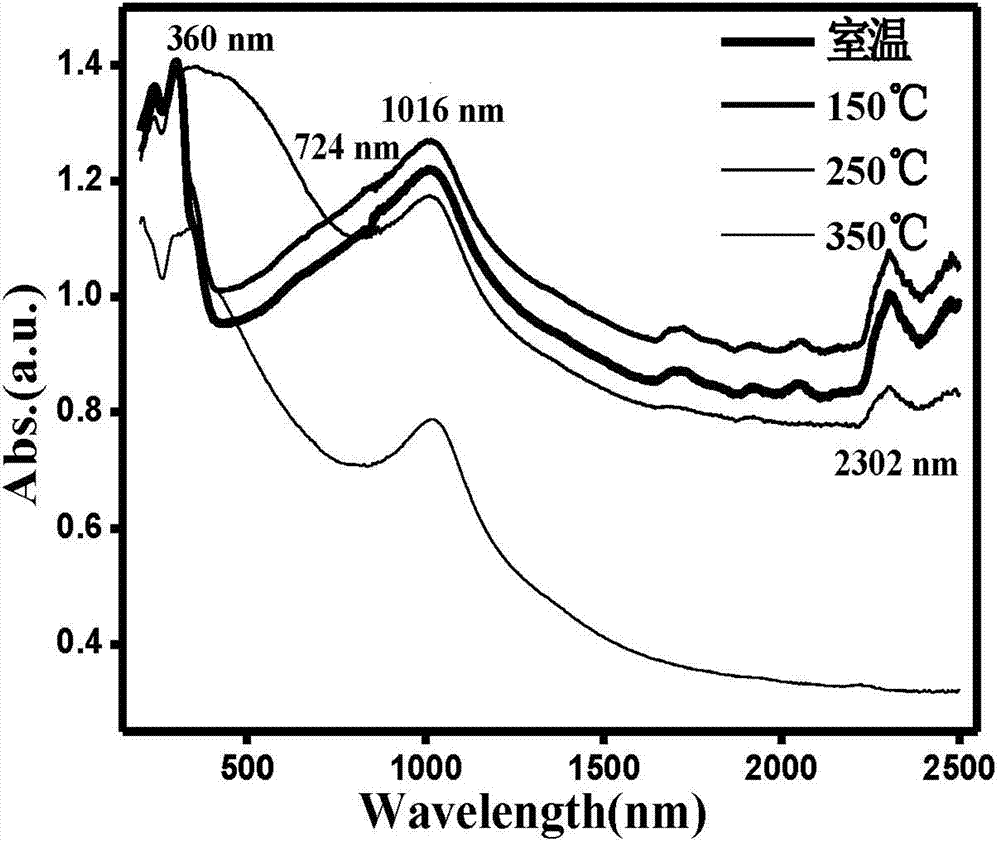

[0018] Embodiment 1: A novel zinc-based infrared coating with adjustable infrared emissivity. In the novel zinc-based infrared coating of the present invention, the zinc powder plays a catalytic role in the heating process, so that the carbonization of the compound in the coating occurs while the metal Oxidation, these nano-substances recombine to change the original state of the coating, and finally change the size of the infrared emissivity, and change the light absorption of a certain wavelength, especially for ultraviolet to near infrared, the absorption of light is significantly reduced. Specifically made through the following steps:

[0019] 1) Take 50 parts by mass of zinc powder, 20 parts by mass of component A of polyurethane AB material, and 20 parts by mass of component B of polyurethane AB material, put in 20 parts by mass of butyl acetate, mix and stir evenly;

[0020] 2) Take the mixed solution obtained in step 1), and use a pen to evenly coat the metal aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com