Method for transferring fluorinated graphene

A technology of fluorinated graphene and graphene, which is applied in the field of new materials, can solve problems such as inapplicable fluorinated graphene, and achieve the effects of promoting application and mass production, high degree of fluorination, and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

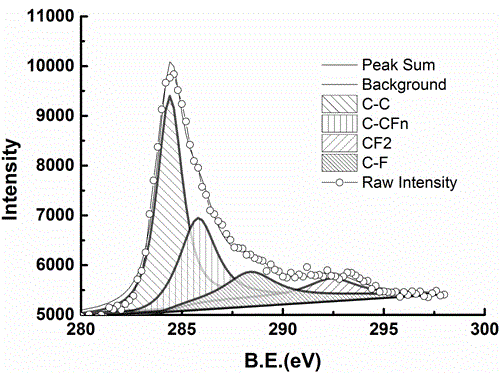

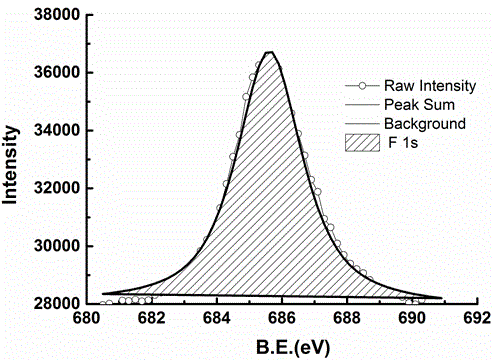

[0020] 1) The purchased graphene sample is a single-layer graphene grown on copper foil, taking a size of 1x1cm, using XeF 2 Fluorinating it as a fluorinating agent to obtain a fluorinated graphene sample;

[0021] 2) Put it on a 2-inch glass and fix it with PI tape. Spin-coat PMMA uniformly at a speed of 500r / min for 5 seconds and 4000r / min for 60 seconds. The thickness of PMMA is 270nm;

[0022] 3) Bake the sample at 105 degrees Celsius for 3 minutes;

[0023] 4) Remove the adhesive tape that fixes the fluorinated graphene, and cut off the tape to ensure that the fluorinated graphene is covered by PMMA. Adjust the regulated power supply to 1.37V, use the Pt electrode as the anode, the copper foil of fluorinated graphene as the cathode, and use the NaOH solution with a concentration of 2.5mol / L as the electrolyte. It can be seen that the fluorinated graphene and copper foil are slow Slowly peel off.

[0024] 5) After the complete peeling off, the fluorinated graphene falls...

Embodiment 2

[0027] 1) The purchased graphene sample is a single-layer graphene grown on copper foil, with a size of 5x5mm, using SF 6 Plasma fluorinated it to obtain a fluorinated graphene sample;

[0028] 2) Put it on a 2-inch glass and fix it with PI tape, spin-coat PMMA evenly at a speed of 500r / min for 5 seconds and 4000r / min for 60 seconds, and the thickness of PMMA is: 280nm;

[0029] 3) Bake the sample at 110 degrees Celsius for 3 minutes;

[0030] 4) Remove the adhesive tape that fixes the fluorinated graphene, and cut off the tape to ensure that the fluorinated graphene is covered by PMMA. Adjust the regulated power supply to 1.37V, use the Pt electrode as the anode, the copper foil of fluorinated graphene as the cathode, and use the NaOH solution with a concentration of 2.5mol / L as the electrolyte. It can be seen that the fluorinated graphene and copper foil are slow Slowly peel off.

[0031] 5) After the complete peeling off, the fluorinated graphene falls into the electroly...

Embodiment 3

[0034] 1) The purchased graphene sample is multilayer graphene grown on copper foil, with a size of 5x5mm, and fluorinated it with SF6 plasma to obtain a fluorinated graphene sample;

[0035] 2) Put it on a 2-inch glass and fix it with PI tape, spin-coat PMMA evenly at a speed of 500r / min for 5 seconds and 4000r / min for 60 seconds, and the thickness of PMMA is: 260nm;

[0036] 3) Bake the sample at 110 degrees Celsius for 3 minutes;

[0037] 4) Remove the adhesive tape that fixes the fluorinated graphene, and cut off the tape to ensure that the fluorinated graphene is covered by PMMA. Adjust the regulated power supply to 1.37V, use the Pt electrode as the anode, the copper foil of fluorinated graphene as the cathode, and use the NaOH solution with a concentration of 2.5mol / L as the electrolyte. It can be seen that the fluorinated graphene and copper foil are slow Slowly peel off.

[0038] 5) After the complete peeling off, the fluorinated graphene falls into the electrolyte,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com