Preparation method of fluorinated graphene foam

A technology of fluorinated graphene and graphene foam, which is applied in the field of new materials, can solve problems such as the inability to prepare fluorinated graphene foam, and achieve the effects of high fluorination degree, good fluorination properties, and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take a cylindrical graphene foam with a diameter of 1 cm and a height of 0.5 cm, place it on a 4-inch liner, put it into the sample delivery chamber of the deep reaction etching machine, and pump the air pressure of the sample delivery chamber to 10 -3 Below Torr, it is sent into the reaction chamber; after the sample is fixed, the air pressure in the reaction chamber is pumped to 10 -6 Below Torr, then pass into SF 6 Gas, flow rate is 100 sccm; for SF 6 Perform plasma excitation with a power of 200W, and the reaction time is 1 minute; after the reaction is completed, fill with nitrogen, and when the pressure in the reaction chamber is the same as that of the sample delivery chamber, transfer the sample to the sample delivery room, and continue to fill with nitrogen until it reaches atmospheric pressure Remove the sample on the liner. At this point, the graphene foam has reacted to generate fluorinated graphene foam.

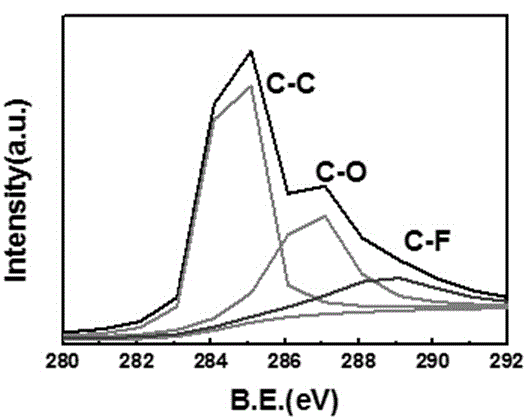

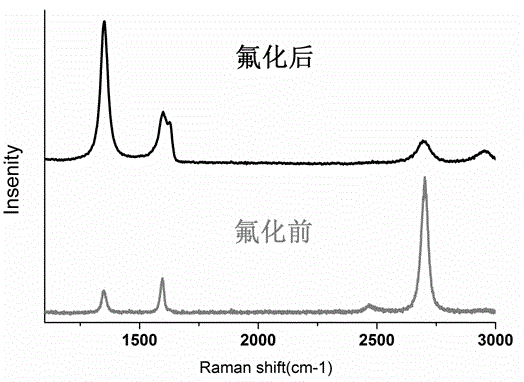

[0018] Carry out XPS characterization to the flu...

Embodiment 2

[0020] Take 1x1x1cm 3 Large and small cubic graphene foam samples are placed on a 4-inch liner, put into the sample delivery chamber, and the air pressure in the sample delivery chamber is pumped to 10 -3 Below Torr, it is sent into the reaction chamber; after the sample is fixed, the air pressure in the reaction chamber is pumped to 10 -6 Below Torr, then pass into SF 6 Gas, flow rate is 100 sccm; for SF 6 Perform plasma excitation with a power of 25W, and the reaction time is 20 minutes; after the reaction is completed, fill with nitrogen gas, and when the pressure of the reaction chamber is the same as that of the sample delivery chamber, transfer the sample to the sample delivery chamber, and continue to fill with nitrogen gas until it reaches atmospheric pressure The sample on the liner was taken out to obtain the fluorinated graphene foam.

Embodiment 3

[0022] Get diameter and be 4 inches, the disc-shaped graphene foam that height is 0.5cm, and it is placed on the liner of 4 inches of size, puts into the sample delivery chamber of deep reaction etching machine, the air pressure of sample delivery chamber is pumped to 10 -3 Below Torr, it is sent into the reaction chamber; after the sample is fixed, the air pressure in the reaction chamber is pumped to 10 -6 Below Torr, then pass into SF 6 Gas, flow rate is 100 sccm; for SF 6 Perform plasma excitation with a power of 300W, and the reaction time is 30s; after the reaction is completed, fill in nitrogen gas, and when the pressure in the reaction chamber is the same as that in the sample delivery room, transfer the sample to the sample delivery room, and continue to fill in nitrogen gas until it reaches atmospheric pressure Remove the sample on the liner. At this point, the graphene foam on the copper grid has reacted to form fluorinated graphene foam.

[0023] According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com