Seepage and collapse prevention structure for foundation filling of drainage pipeline and construction method of seepage and collapse prevention structure

A technology for drainage pipes and construction methods, applied in infrastructure engineering, construction, etc., can solve problems such as interface deformation, pipe cracking, land subsidence, etc., and achieve the effects of preventing soil erosion and loss, preventing rainwater and sewage leakage, and lowering the groundwater level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

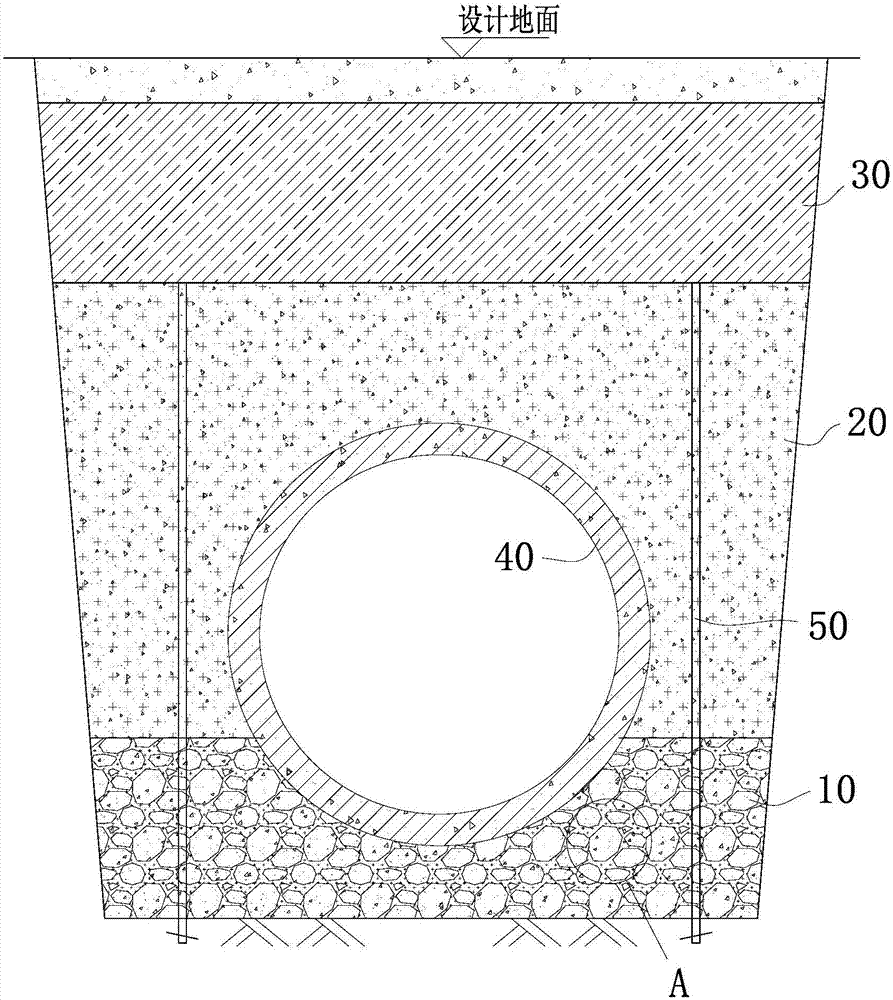

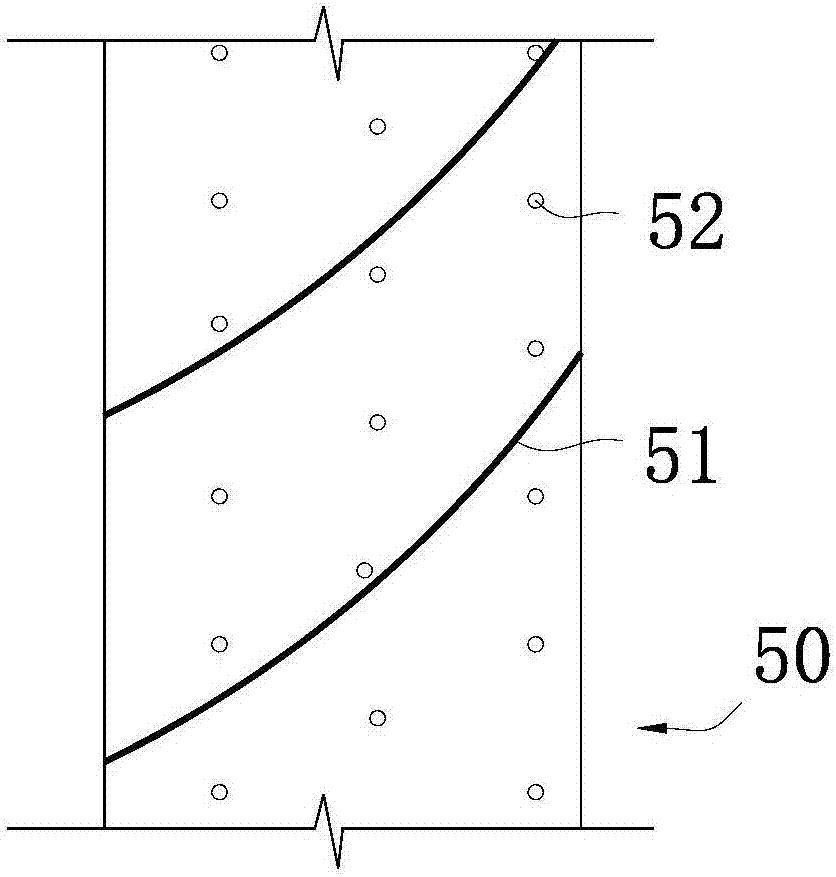

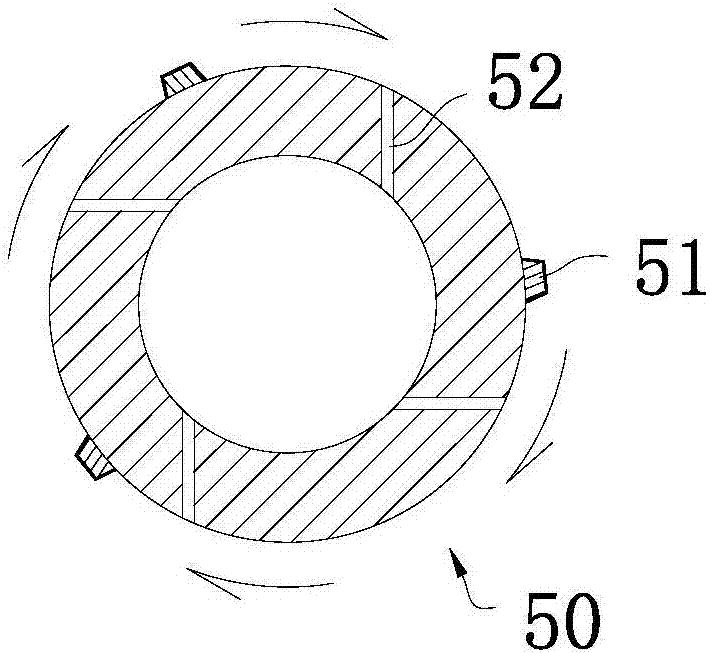

[0022] refer to Figure 1 to Figure 4 , an anti-seepage and anti-collapse structure for drainage pipeline foundation filling in the present invention, comprising a sandstone base layer 10, a sandstone base groove layer 20 and a clay layer 30 formed by filling sequentially from bottom to top, and the drainage pipeline is laid on the sandstone base layer 10 40, the grouting pipe 50 is anchored in the sandstone base groove layer 20, the outer wall of the grouting pipe 50 is provided with an immersed pipe thread 51, the wall of the grouting pipe 50 is distributed with grouting holes 52 in a staggered array, and the opening of the grouting holes 52 The hole position needs to avoid the immersed pipe thread 51.

[0023] Wherein, the opening direction of the grouting hole 52 is staggered from the tangential direction of the rotation of the grouting pipe 50 , so as to prevent sand and gravel particles from blocking the grouting hole 52 when the grouting pipe 50 is anchored into the soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com