Permeable pavement with semi-rigid permeable cushion and construction method thereof

A technology of permeable pavement and construction method, which is applied to the condensable pavement, roads, roads and other directions paved on site, can solve the problems of inconvenience of driving and pedestrians, inclination and dislocation of permeable pavement, achieve good anti-scour performance and avoid erosion and loss , the effect of good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

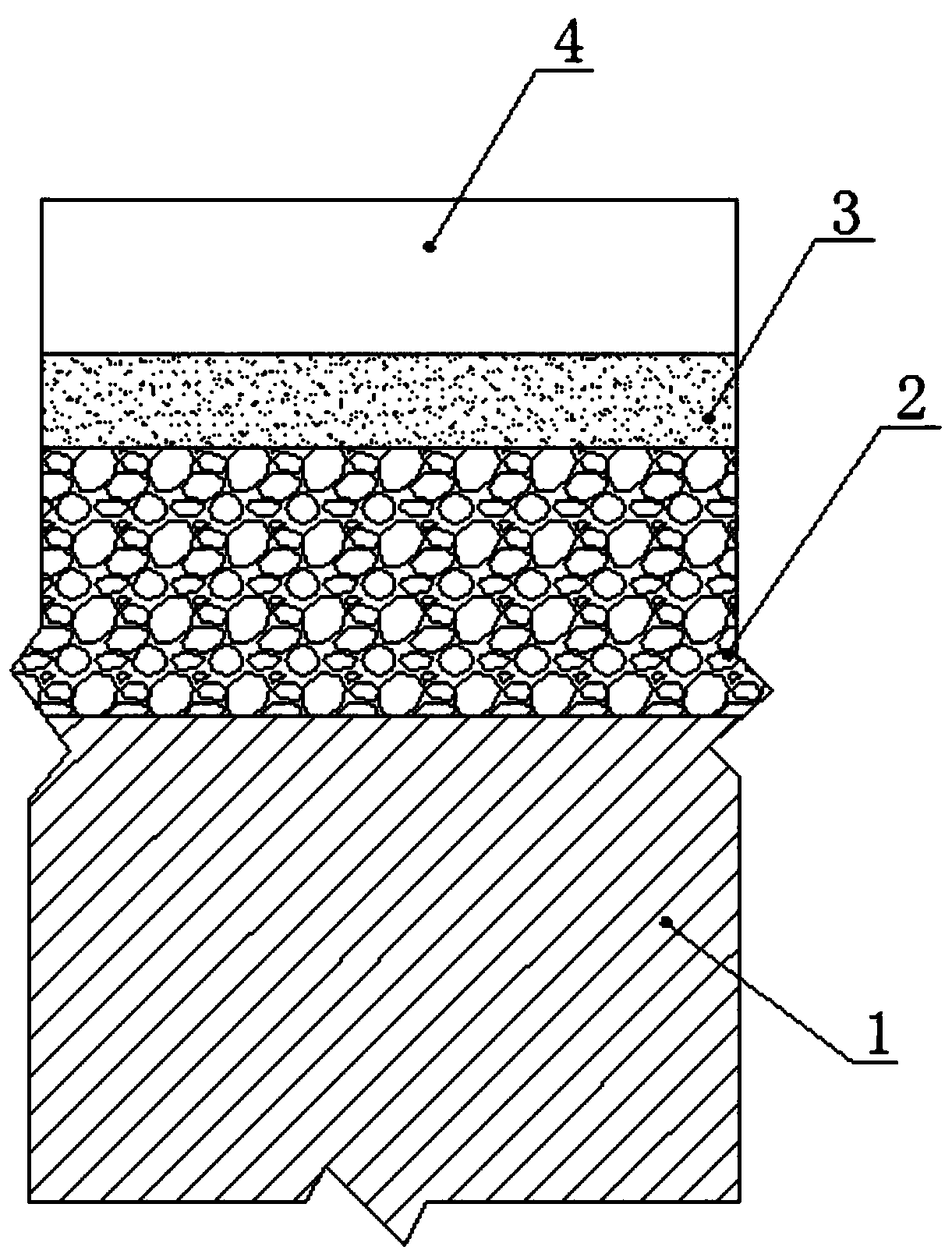

[0034] A construction method for a permeable pavement containing a semi-rigid permeable cushion, combining figure 1 shown, including the following steps:

[0035] 1) Construction of graded crushed stone foundation cushion: according to the construction requirements of ordinary permeable concrete pavement, pave graded crushed stone foundation cushion 2 on road bed 1;

[0036] 2) Preparation of curing agent: in parts by mass, weigh 100 parts of cement, 0.5 part of attapulgite, 0.5 part of polyacrylamide, and 100 parts of water, and mix them uniformly to obtain a liquid curing agent;

[0037] 3) Preparation of permeable mortar: Spray the liquid curing agent prepared in step 2) into the medium sand after sieving the particles with a particle size less than 1 mm, and spray the liquid curing agent prepared in step 2), and stir until the sand is evenly and fully contacted with the curing agent to obtain water permeability Mortar; Wherein, the consumption of liquid curing agent is 1 / ...

Embodiment 2

[0042] A construction method for a permeable pavement containing a semi-rigid permeable cushion, combining figure 1 shown, including the following steps:

[0043] 1) Construction of graded crushed stone foundation cushion: according to the construction requirements of ordinary permeable concrete pavement, pave graded crushed stone foundation cushion 2 on road bed 1;

[0044] 2) Preparation of curing agent: by mass parts, weigh 100 parts of cement, nano-SiO 2 1.5 parts, 0.8 parts of polyacrylamide, 100 parts of water, mix well to obtain a liquid curing agent;

[0045]3) Preparation of permeable mortar: Spray the liquid curing agent prepared in step 2) into the medium sand after sieving the particles with a particle size less than 1 mm, and spray the liquid curing agent prepared in step 2), and stir until the sand is evenly and fully contacted with the curing agent to obtain water permeability Mortar; Wherein, the consumption of liquid curing agent is 1 / 8 of sand quality;

[...

Embodiment 3

[0049] A construction method for a permeable pavement containing a semi-rigid permeable cushion, combining figure 1 shown, including the following steps:

[0050] 1) Construction of graded crushed stone foundation cushion: according to the construction requirements of ordinary permeable concrete pavement, pave graded crushed stone foundation cushion 2 on road bed 1;

[0051] 2) Preparation of curing agent: by mass parts, weigh 100 parts of cement, nano-CaCO 3 1 part, 1 part of hydroxypropyl methylcellulose, 100 parts of water, mix well to obtain a liquid curing agent;

[0052] 3) Preparation of permeable mortar: Spray the liquid curing agent prepared in step 2) into the coarse sand after the particles with a particle size of less than 1mm have been sieved, and spray the liquid curing agent prepared in step 2), and stir until the sand is evenly and fully contacted with the curing agent to obtain water permeability Mortar; Wherein, the consumption of liquid curing agent is 1 / 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com