Dust-removal foaming agent

A foam generation, weight percentage technology, applied in the direction of dust prevention, use of liquid separation agent, prevention of fire, etc., can solve the problems of high investment, secondary water pollution, large water consumption, etc., and achieves low surface tension, stable performance, high efficiency Strong foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] This dust-removing foam generator includes the following components in weight percentage: 0.3% sodium dioctyl sulfosuccinate, 0.1% sodium dioctyl sulfosuccinate, 0.1% nonylphenol polyoxyethylene ether, coconut oil diethanol Amide 0.1%, triethanolamine 0.1%, fatty acid polyoxyethylene ester 0.02%, pentaerythritol oleate 0.1%, and the balance is water.

[0014] For on-site application, it needs to be configured as an aqueous solution, the concentration of the solution is diluted to 1% (wt%), it is added to the foam generator, and the generated foam is transported to the cutting head of the roadheader to cover the cutting head, and the cutting head is placed to generate The dust diffuses outwards and makes it settle. The specific on-site dust concentration measurement results are shown in Table 1 below:

[0015]

[0016] It can be seen from Table 1 that the formula has a good dust reduction effect, the dust reduction rate of the whole dust can reach 95.78%, and the dust...

Embodiment 2

[0018] This dust-removing foam generator includes the following components in weight percentage: 0.5% sodium dioctyl sulfoplatinate, 1% sodium dioctyl sulfosuccinate, 1% nonylphenol polyoxyethylene ether, coconut oil diethanol Amide 0.5%, triethanolamine 0.5%, fatty acid polyoxyethylene ester 0.1%, pentaerythritol oleate 0.2%, and the balance is water.

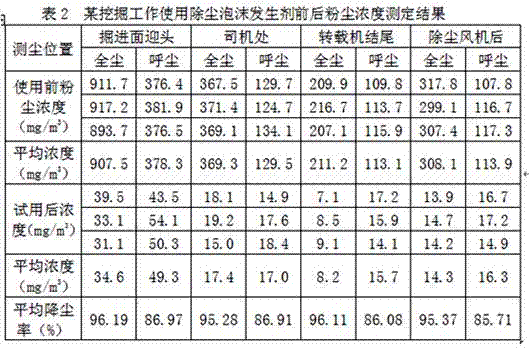

[0019] For on-site application, it needs to be configured as an aqueous solution, the concentration of the solution is diluted to 0.2% (wt%), it is added to the foam generator, and the generated foam is transported to the vicinity of the cutting head of the roadheader to cover the cutting head, and the cutting head is placed to generate The dust diffuses outwards and makes it settle. The specific on-site dust concentration measurement results are shown in Table 2 below:

[0020]

[0021] It can be seen from Table 2 that the formula has a good dust reduction effect, the dust reduction rate of the whole dust can reach 96.19%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com