Multi-station automatic bag centrifugal dehydrator

A centrifugal dehydrator and centrifugal dehydration technology, applied in the direction of manufacturing tools, metal processing equipment, cleaning/processing machinery of casting materials, etc., can solve the problems of expensive resin sand, pungent smell, etc., achieve short dehydration time, The effect of reducing labor intensity and low moisture content of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

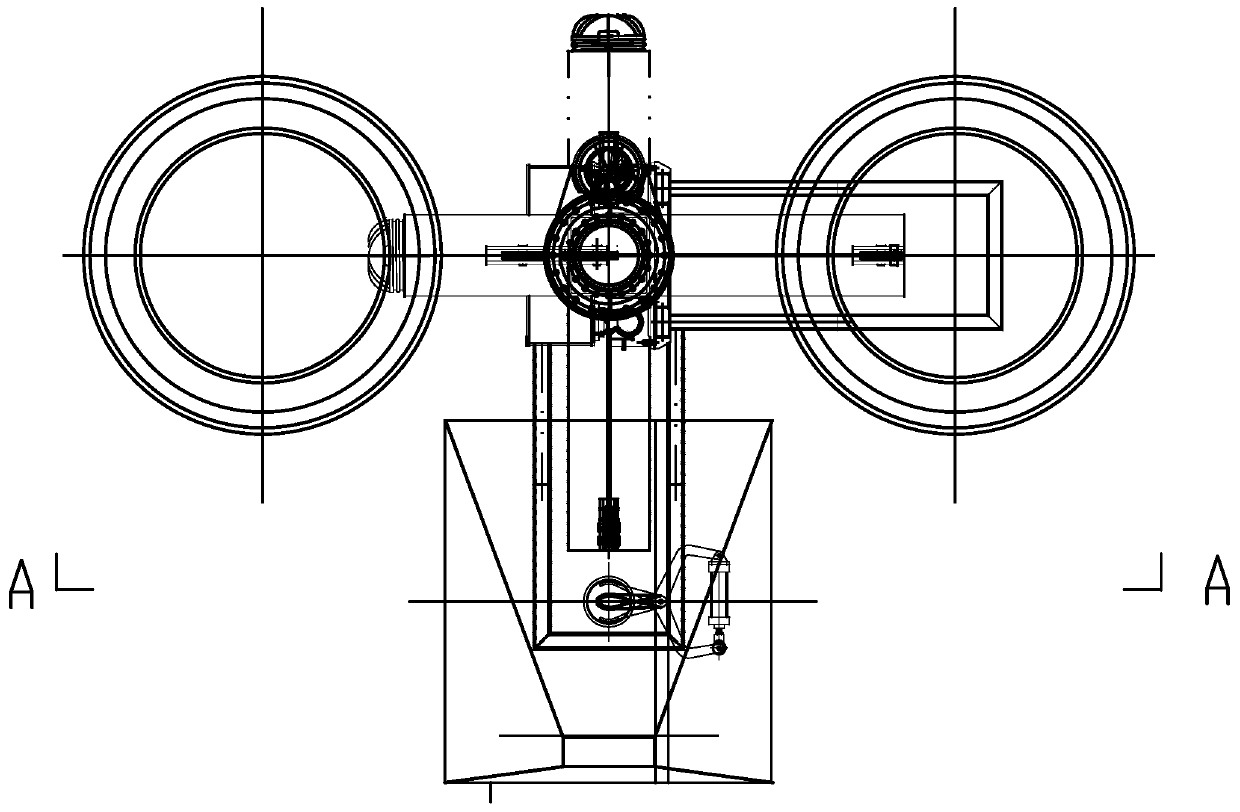

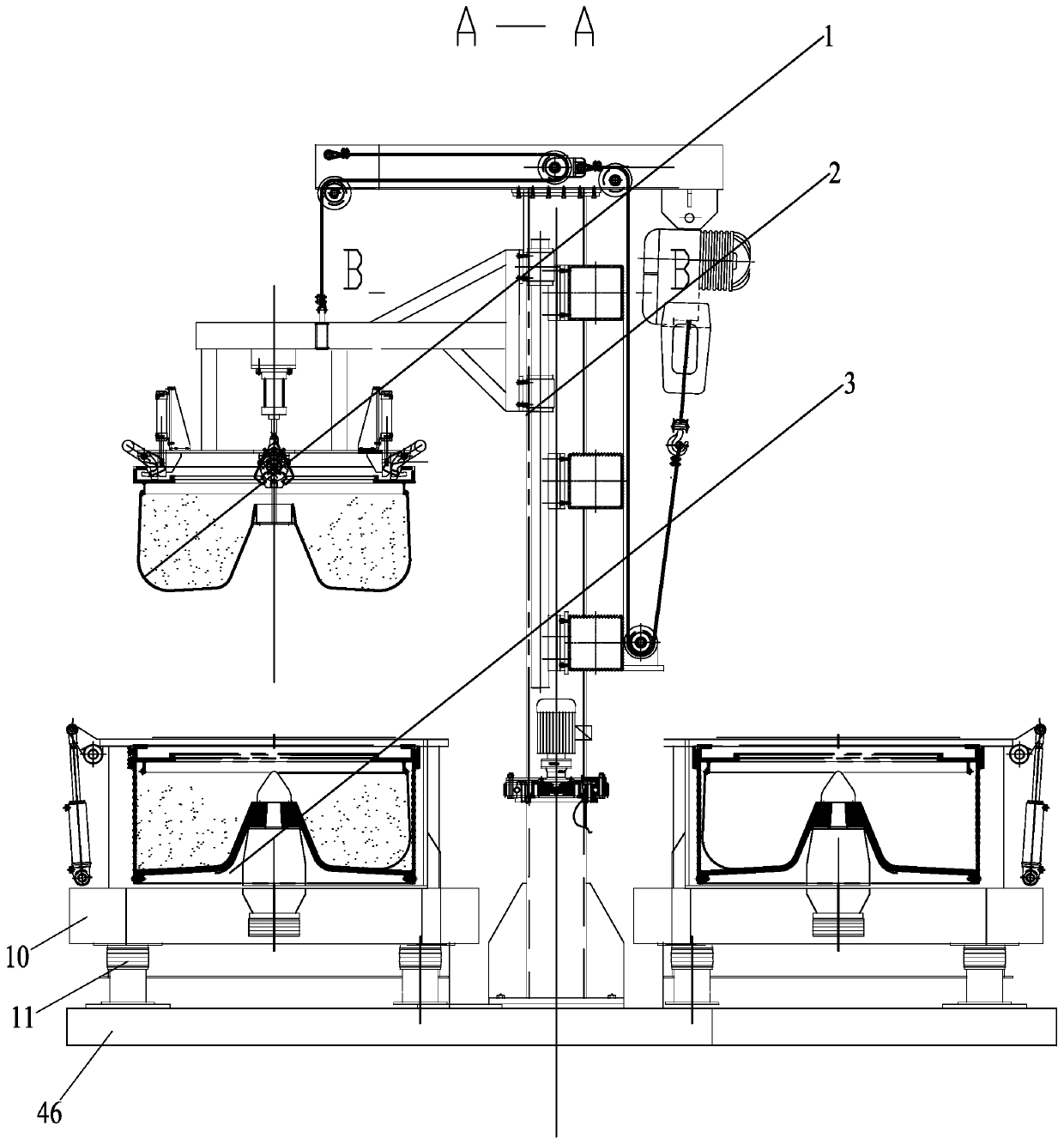

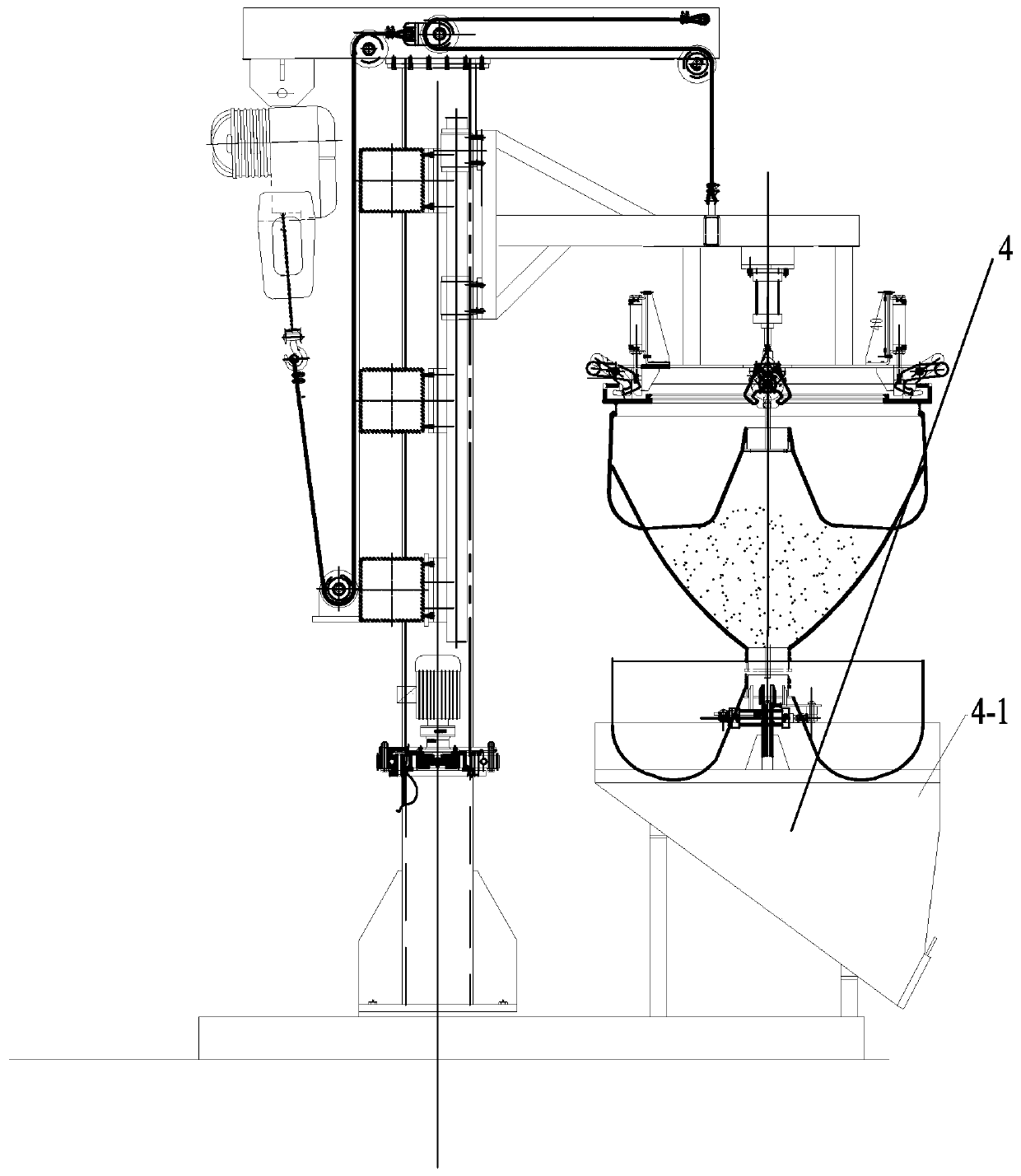

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Figure 1~15 Including filter bag 1, lifting ring 1-1, lifting plate 1-2, rotary compression bayonet 1-3, filter bag automatic pick-and-place manipulator device 2, bag centrifugal dehydration device 3, sand unloading device 4, barrel cover 5. Outer barrel 6, feeding hopper 7, inner barrel 8, drum rotating device 9, machine base 10, shock absorber 11, traction pulley 12, lifting frame 13, electric chain hoist 14, lifting mechanical claw device 15, pick and place Device 16, rotating bracket 17, cylindrical guide rail 18, rotating mechanism 19, open-type linear rolling bearing 20, bag mouth expansion manipulator device 21, hinged connecting rod 22, jaw 23, second cylinder 24, cylinder mounting seat 25, self-locking Lifting hook 26, lock block 27, pocket ring 28, pocket opening finger 29, finger hinge shaft 30, round nut 31, fourth cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com