A kind of manufacturing method of flexible 3D grinding tool

A manufacturing method, 3D technology, applied in the direction of manufacturing tools, abrasives, coatings, etc., can solve the problems of deep scratches, burns, and easy clogging of workpieces, and achieve improved bond strength and stability, high stability and adhesion knot strength, improve the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] An adhesive composition for flexible 3D grinding tools, comprising the following raw materials in parts by weight:

[0066] Adhesive A 2 parts

[0067] Leveling resin B 5 parts

[0068] Adhesive C 50 parts;

[0069] Described adhesive A comprises the raw material of following weight portion:

[0070] Photocurable resin a 15 parts

[0071] 85 parts of thermosetting resin a;

[0072] The leveling resin B is photocurable resin b;

[0073] The adhesive C includes the following raw materials in parts by weight:

[0074] Photocurable resin a 30 parts

[0075] Thermosetting resin a 70 parts.

[0076] The photocurable resin a is epoxy acrylate; the photocurable resin b is a mixture of organic acid modified epoxy acrylate and polyester acrylate in a weight ratio of 3:1; the thermal Cured resin a is at least one of glycidyl ester epoxy resin and glycidyl ether epoxy resin.

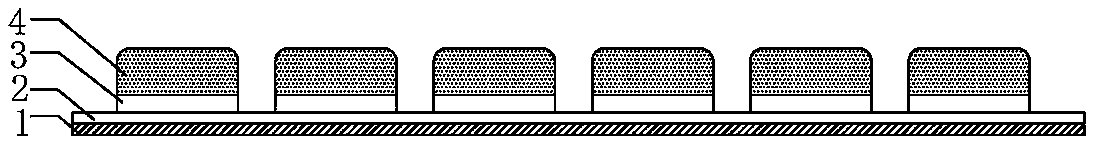

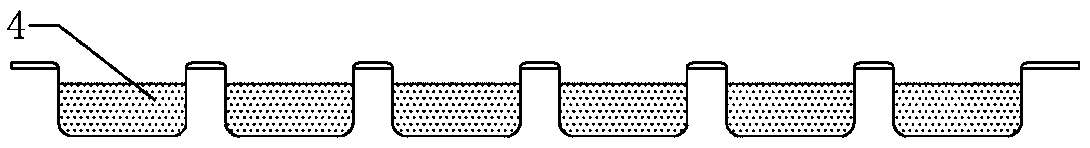

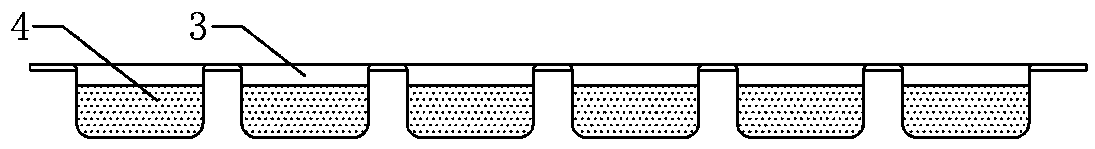

[0077] A flexible 3D abrasive made from the above-mentioned adhesive composition for flexible 3D ab...

Embodiment 2

[0110] The difference between this embodiment and above-mentioned embodiment 1 is:

[0111] An adhesive composition for flexible 3D grinding tools, comprising the following raw materials in parts by weight:

[0112] Adhesive A 3 parts

[0113] Leveling resin B 10 parts

[0114] Adhesive C 80 parts;

[0115] Described adhesive A comprises the raw material of following weight portion:

[0116] Photocurable resin a 18 parts

[0117] 82 parts of thermosetting resin a;

[0118] The leveling resin B is photocurable resin b;

[0119] The adhesive C includes the following raw materials in parts by weight:

[0120] Photocurable resin a 27 parts

[0121] Thermosetting resin a 73 parts.

[0122] The photocurable resin a is epoxy acrylate; the photocurable resin b is a mixture of organic acid modified epoxy acrylate and polyester acrylate in a weight ratio of 6:1; the thermal Cured resin a is at least one of glycidyl ester epoxy resin and glycidyl ether epoxy resin.

[0123] A f...

Embodiment 3

[0155] The difference between this embodiment and above-mentioned embodiment 1 is:

[0156] An adhesive composition for flexible 3D grinding tools, comprising the following raw materials in parts by weight:

[0157] Adhesive A 4 parts

[0158] Leveling resin B 15 parts

[0159] Adhesive C 120 parts;

[0160] Described adhesive A comprises the raw material of following weight portion:

[0161] Photocurable resin a 23 parts

[0162] 77 parts of thermosetting resin a;

[0163] The leveling resin B is photocurable resin b;

[0164] The adhesive C includes the following raw materials in parts by weight:

[0165] Photocurable resin a 23 parts

[0166] Thermosetting resin a 77 parts.

[0167] The photocurable resin a is epoxy acrylate; the photocurable resin b is a mixture of organic acid modified epoxy acrylate and polyester acrylate in a weight ratio of 9:1; the thermal Cured resin a is at least one of glycidyl ester epoxy resin and glycidyl ether epoxy resin.

[0168] A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com