Sound insulation screen capable of achieving self-generating electricity

A sound insulation barrier and self-generating technology, applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of increasing investment and operating costs, failure of sound insulation barriers, etc. To reduce the cost of operation and maintenance, eliminate hidden dangers, and reduce cyclic loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

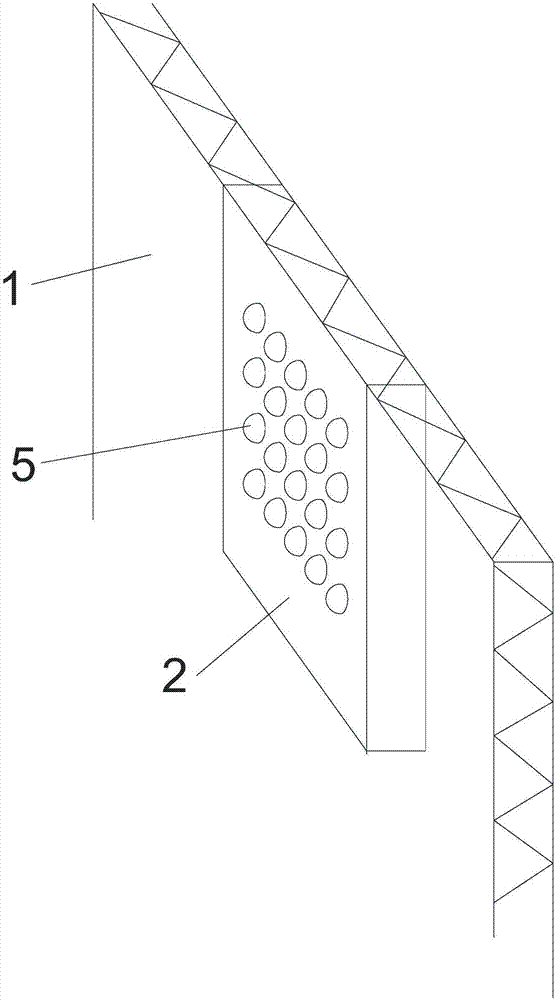

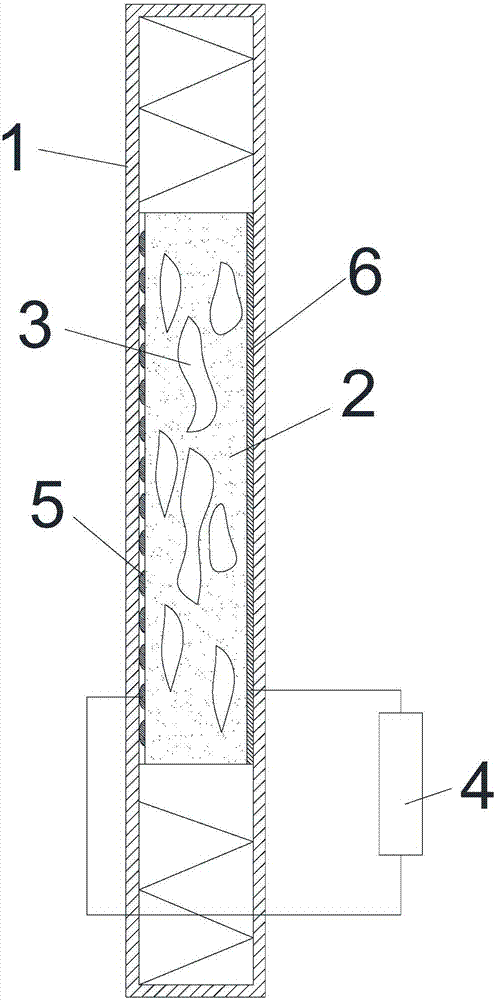

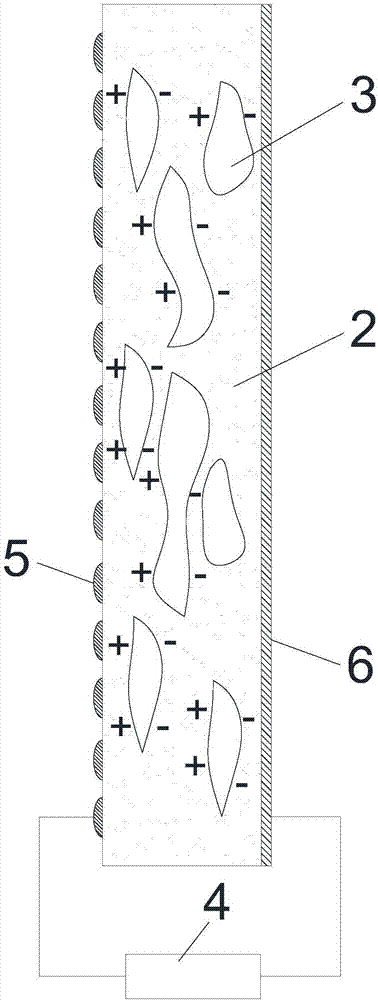

[0030] Refer to the attached figure 1 to the attached Figure 4 , a self-generating sound insulation barrier in this embodiment, which includes a sound insulation wall 1, a foam film 2 with electrostatic charge through polarization treatment inside the sound insulation wall 1, a foam film 2 connected to the foam film 2 A flexible sensing electrode 5 on the surface of one side of the road and capable of inducing charges, a back sensing electrode 6 located on the side of the foam film 2 away from the road and capable of inducing charges, the foam film 2 is an electret material or / and a ferroelectric material, The foam film 2 is flexible so that it can be deformed when subjected to external force. The foam film 2 has several pores 3 inside. When the foam film 2 is deformed, the size of the pores 3 changes to generate electric charge output.

[0031] The flexible sensing electrode 5 is electrically connected to the external load 4 , and the other end of the external load 4 opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com