Clutch and electric compound transmission type pneumatic screw press with bottom dead center

A composite transmission and clutch technology, which is applied in presses, forging/pressing/hammering machines, forging/pressing/hammer devices, etc., can solve the safety problems of equipment and staff, the separation of equipment screw and slider, and the short stroke. meet and other problems, to achieve the effect of reducing mechanical stress and thermal contact time, reducing weight and fast striking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

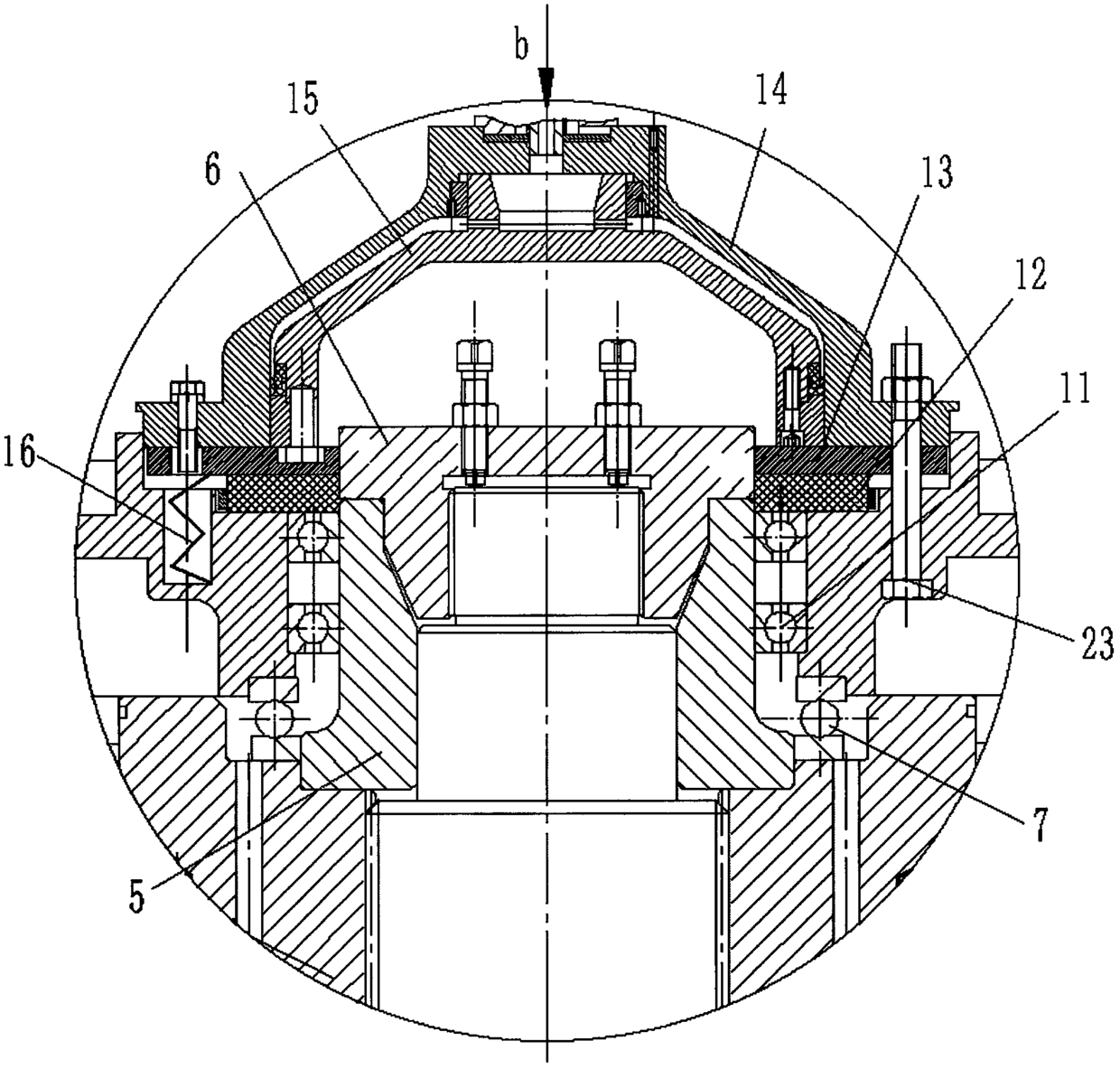

[0018] exist figure 1 , figure 2 Among them, the clutch and electric compound transmission type pneumatic screw press with bottom dead center of the present invention includes a fuselage 1, a screw rod 2 vertically installed through the inner hole of the upper beam of the fuselage, and installed on the upper plane groove of the upper beam of the fuselage The lower load-bearing bearing 3 in the groove is installed on the screw rod through threaded connection and pressed against the nut 4 on the upper end surface of the lower load-bearing bearing, the intermediate body 5 installed above the nut, and the nut gland 6 installed on the top of the screw rod above the intermediate body, The intermediate load bearing 7 installed in the plane groove on the nut, the main motor 8 installed on one side of the fuselage, the belt pulley 9 installed on the output shaft of the main motor, the large bearing installed on the upper part of the intermediate load bearing and driven by belt transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com