Steel belt reel discharging device, using method of steel belt reel discharging device and grinding miller

A grinding machine and steel coil technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as difficult to complete scraper surface and cutting edge grinding, and achieve the effect of simple and convenient structure, convenient and reliable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

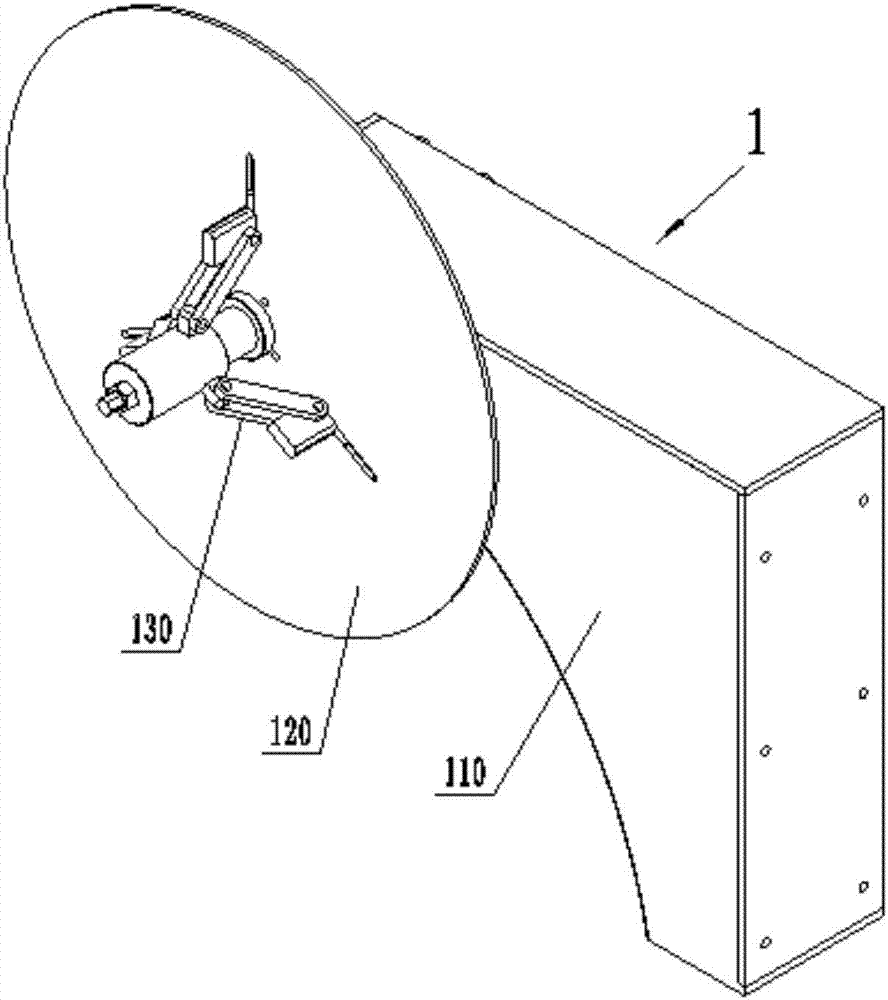

[0063] Such as image 3 , Figure 4 , Figure 5 As shown, a steel strip unwinding device in this embodiment is used for clamping ink scrapers or other soft steel strip coils for grinding with a grinder, which mainly includes a base 110, a rotating shaft 140, and a turntable 120 and clamping mechanism 130.

[0064] Wherein, the base 110 is an L-shaped box structure welded by plates, and the rotating shaft 140 is mainly composed of three sections, which are respectively a supporting section 141 , a limiting section 142 and a guide adjusting section 143 from one end to the other end. Two coaxial belt seat bearings 150 are installed on the front and back sides of the L-shaped box left end, and the support section 141 of the rotating shaft 140 is supported and installed in the two belt seat bearings 150, thereby the rotating shaft 140 rotating shaft can be supported to rotate. The limit section 142 is located in the middle of the rotating shaft 140, and its diameter is larger th...

Embodiment 2

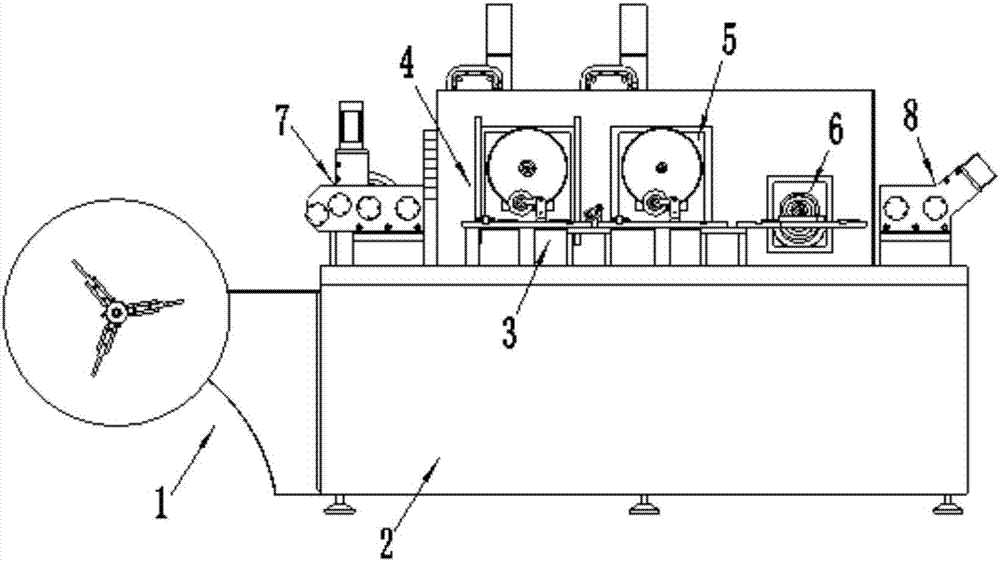

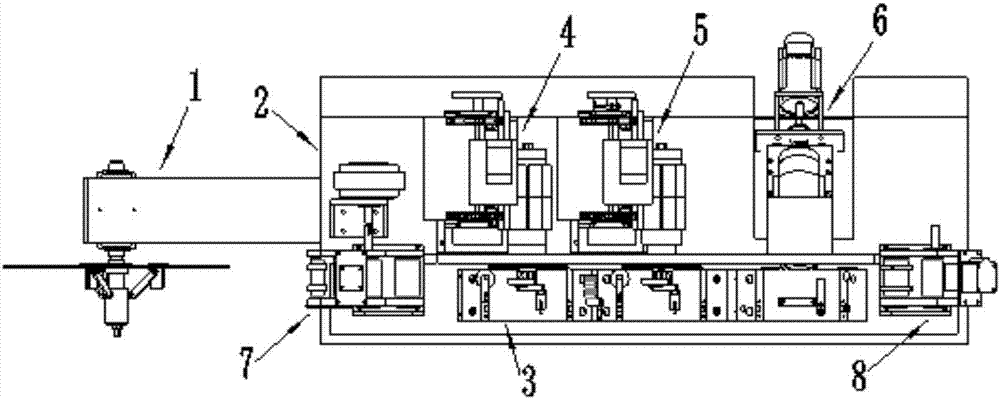

[0072] Such as figure 1 and figure 2 As shown, a grinding machine in this embodiment mainly includes a frame 2, a workbench assembly 3, a steel strip unwinding device 1, a brake assembly 7, a surface grinding assembly, an edge grinding assembly 6 and a drive assembly 8; wherein , the steel strip unwinding device 1 adopts the steel strip unwinding device in Embodiment 1, which is installed on the left side of the frame 2 through the base 110, the brake assembly 7, the surface grinding assembly, and the edge grinding assembly 6 and the driving assembly 8 are arranged sequentially on the frame 2 along the processing direction, that is, from left to right, and the workbench assembly 3 is installed on the frame 2 corresponding to the positions of the surface grinding assembly and the edge grinding assembly 6 . Specifically in this machine tool, the functions of each part are: the workbench assembly 3 is used to support the steel belt of the ink scraper, the surface grinding asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com