Material mixing device for injection moulding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

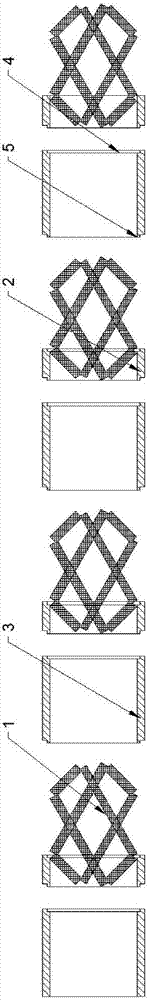

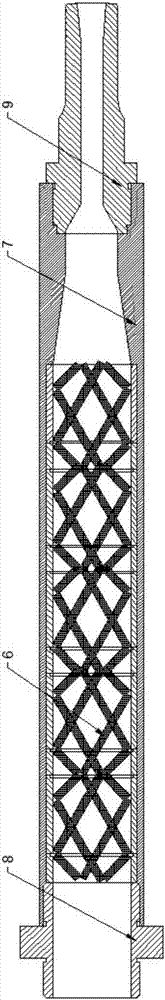

[0031] When installing, put the fixed block 2 and the connecting block 3 into the feed pipe 7 at intervals, and ensure that the connecting flange 8 has been installed on the front side. Hit the fixed block 2 and the connecting block 3 so that the embedding groove 4 fits closely with the collar 5, and finally the discharge port 9 is installed at the end of the feed pipe 7, and the stirring block 1 and the fixed block 2 are welded Connection, the installation of multiple stirring units 6 is completed during the process of installing the fixing block 2 and the connecting block 3 .

Embodiment 2

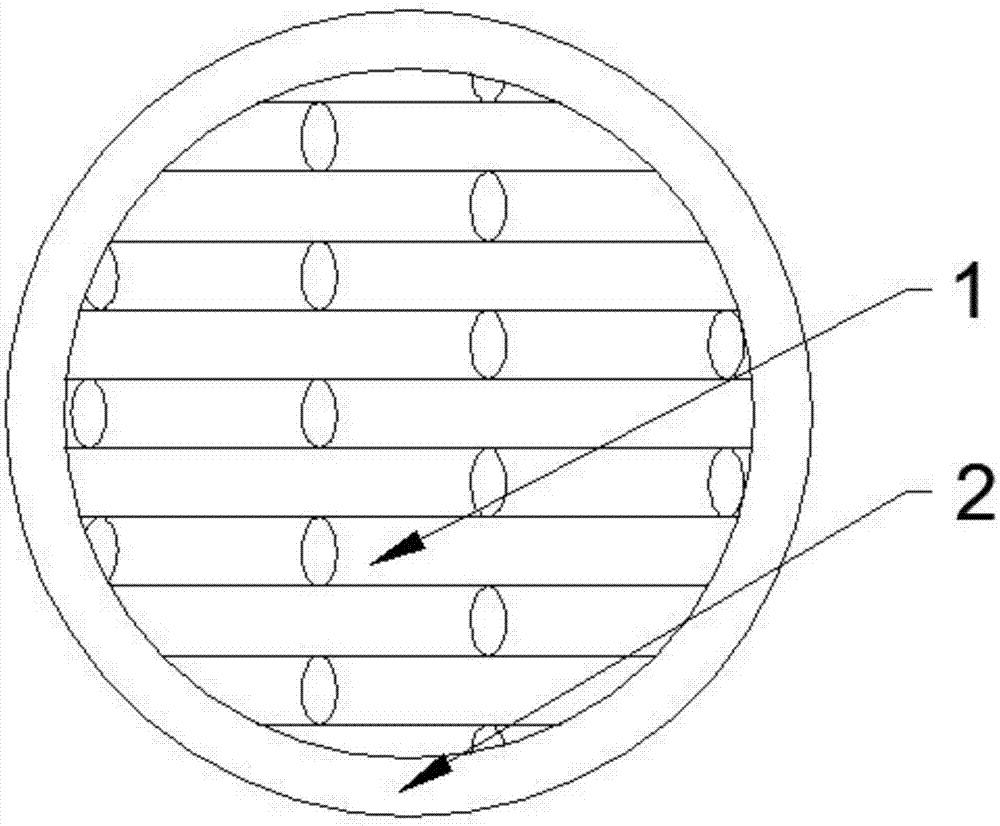

[0033] During production, the input pipes of various ingredients are connected with the connecting flange 8 and sealed and fixed, and various raw materials are input into the feed pipe 7 in proportion, and when the raw materials pass through the stirring block 1, they will follow the The interlaced metal frames, metal strips and metal sheets of the stirring blocks are fused together to realize stirring, and the stirred raw materials flow out from the discharge port 9 after passing through the feed pipe 7 with a reduced inner diameter of the casting to realize injection molding.

Embodiment 3

[0035] According to different raw materials, different types of stirring blocks 1 can be selected to adjust the stirring efficiency and the load on the raw material driving components during stirring. At the same time, the number of stirring units 6 installed can also be selected to adjust the stirring efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com