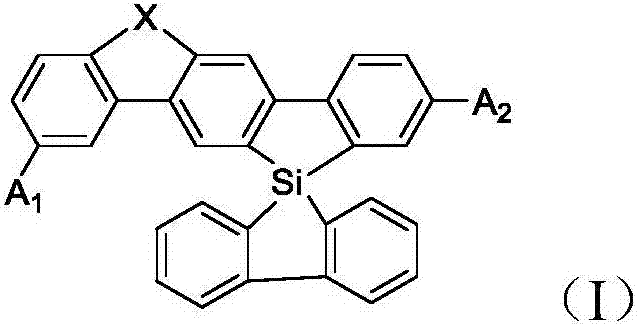

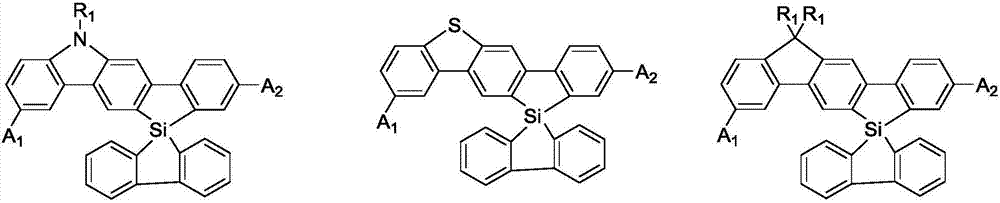

Spirosilafluorene derivative and organic light emitting device prepared therefrom

A technology of derivatives and silafluorene, which is applied in the field of spirosilafluorene derivatives and their organic light-emitting devices, can solve the problems of inability to break through the internal quantum efficiency and high cost, and achieve improved anti-crystallization ability, glass transition temperature, and thermal stability sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

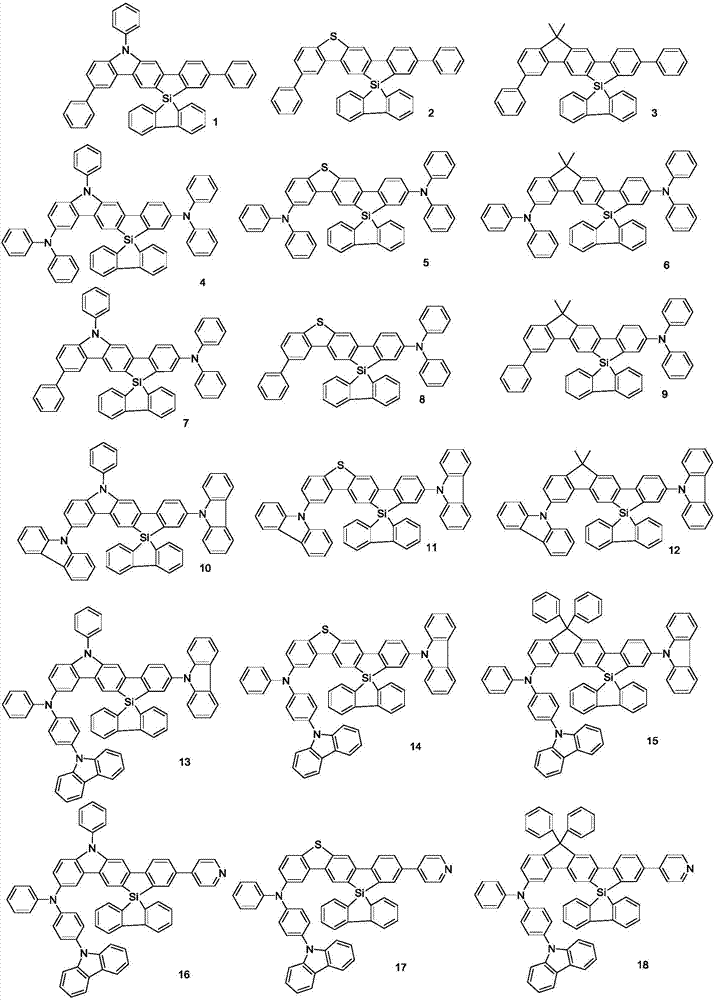

[0046] Embodiment 1: the preparation of compound 1

[0047]

[0048] Step1, take 100mmol of compound 1-1, add an appropriate amount of anhydrous THF to dissolve, cool down to -78°C, add 2.5 equivalents of n-butyllithium dropwise, keep the reaction for 0.5 hours, quickly add 1-2 100mmol dropwise, and slowly heat up to room temperature and react overnight. After the reaction was completed, the solvent was evaporated to dryness, and the crude product was passed through a silica gel column to obtain 1-3, 82 mmol.

[0049]Step2, 82mmol of compound 1-3, add an appropriate amount of anhydrous THF to dissolve, cool down to -78°C, add 3 equivalents of n-butyllithium dropwise, keep warm for 0.5 hours, quickly add trimethyl borate dropwise, and slowly warm up to room temperature , reacted overnight. After the reaction was completed, it was poured into water, and a solid substance was precipitated and filtered, and the crude product was passed through a silica gel column to obtain 1-...

Embodiment 2

[0057] Embodiment 2: the synthesis of compound 2

[0058]

[0059] Step1, take 100mmol of compound 2-1, add an appropriate amount of anhydrous THF to dissolve, cool down to -78°C, add 2.5 equivalents of n-butyllithium dropwise, keep warm for 0.5 hours, quickly add 2-2 100mmol dropwise, and slowly heat up to room temperature and react overnight. After the reaction was completed, the solvent was evaporated to dryness, and the crude product was passed through a silica gel column to obtain 2-3, 82 mmol.

[0060] Step2, 82mmol of compound 2-3, add an appropriate amount of anhydrous THF to dissolve, cool down to -78°C, add 3 equivalents of n-butyllithium dropwise, keep warm for 0.5 hours, quickly add trimethyl borate dropwise, and slowly warm up to room temperature , reacted overnight. After the reaction was completed, it was poured into water, and a solid substance was precipitated and filtered, and the crude product was passed through a silica gel column to obtain 2-4, 69 mmo...

Embodiment 3

[0067] Embodiment 3: the synthesis of compound 3

[0068]

[0069] Step1, take 100mmol of compound 3-1, add an appropriate amount of anhydrous THF to dissolve, cool down to -78°C, add 2.5 equivalents of n-butyllithium dropwise, keep warm for 0.5 hours, quickly drop 3-2 100mmol, and slowly heat up to room temperature, react overnight. After the reaction was completed, the solvent was evaporated to dryness, and the crude product was passed through a silica gel column to obtain 3-3, 82 mmol.

[0070] Step2, 82mmol of compound 3-3, add an appropriate amount of anhydrous THF to dissolve, cool down to -78°C, add 3 equivalents of n-butyllithium dropwise, keep the reaction for 0.5 hours, quickly add trimethyl borate dropwise, and slowly warm up to room temperature , reacted overnight. After the reaction was completed, it was poured into water, and a solid substance was precipitated and filtered, and the crude product was passed through a silica gel column to obtain 3-4, 69 mmol. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com