Buffer convenient to machine

A buffer and cylinder block technology, which is applied in the direction of shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve the problems of difficulty in machining slots for bearing sleeves, complex structure of buffers, and complicated processes, so as to achieve protection from The effect of bumping, reducing process manufacturing costs, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

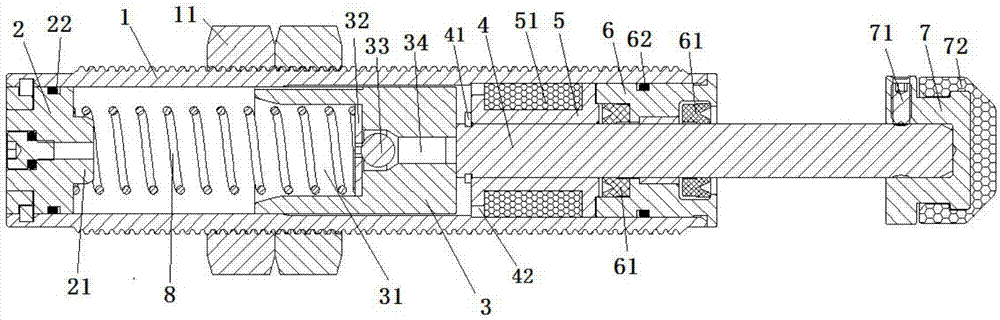

[0012] figure 1 As shown, it relates to a buffer that is easy to process, including a cylinder block 1, a cylinder head 2 is installed at one end of the cylinder body, and a bearing sleeve 5 and a dust seal sheath 6 are installed at the other end in sequence, and the upper end of the bearing sleeve 5 is set A sponge 51 is placed; grooves are respectively opened on both sides of the dust seal sheath 6, and an oil seal 61 is arranged in the groove; a piston 3 and a piston rod 4 are installed in the middle of the cylinder body 1; the inner side of the cylinder head 2 A protruding part 21 is arranged in the axial direction, and a spring installation cavity 31 is provided in the piston 3; a part of the spring 8 arranged in the cylinder 1 is set on the protruding part 21, and the other part is set on the spring mounting cavity. In the cavity 31; the right end of the piston 3 is provided with an oil return hole 34 which runs through the piston 3 and connects the left and right caviti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com