A production process of a car seat steel frame

A production process and seat frame technology, which is used in manufacturing tools, metal processing equipment, auxiliary welding equipment, etc. The frame processing technology is cumbersome, and the seat frame has poor compressive and tensile properties, so as to ensure the quality of the solder joints and the aesthetics of the solder joints, improve the welding quality, and improve the loading quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

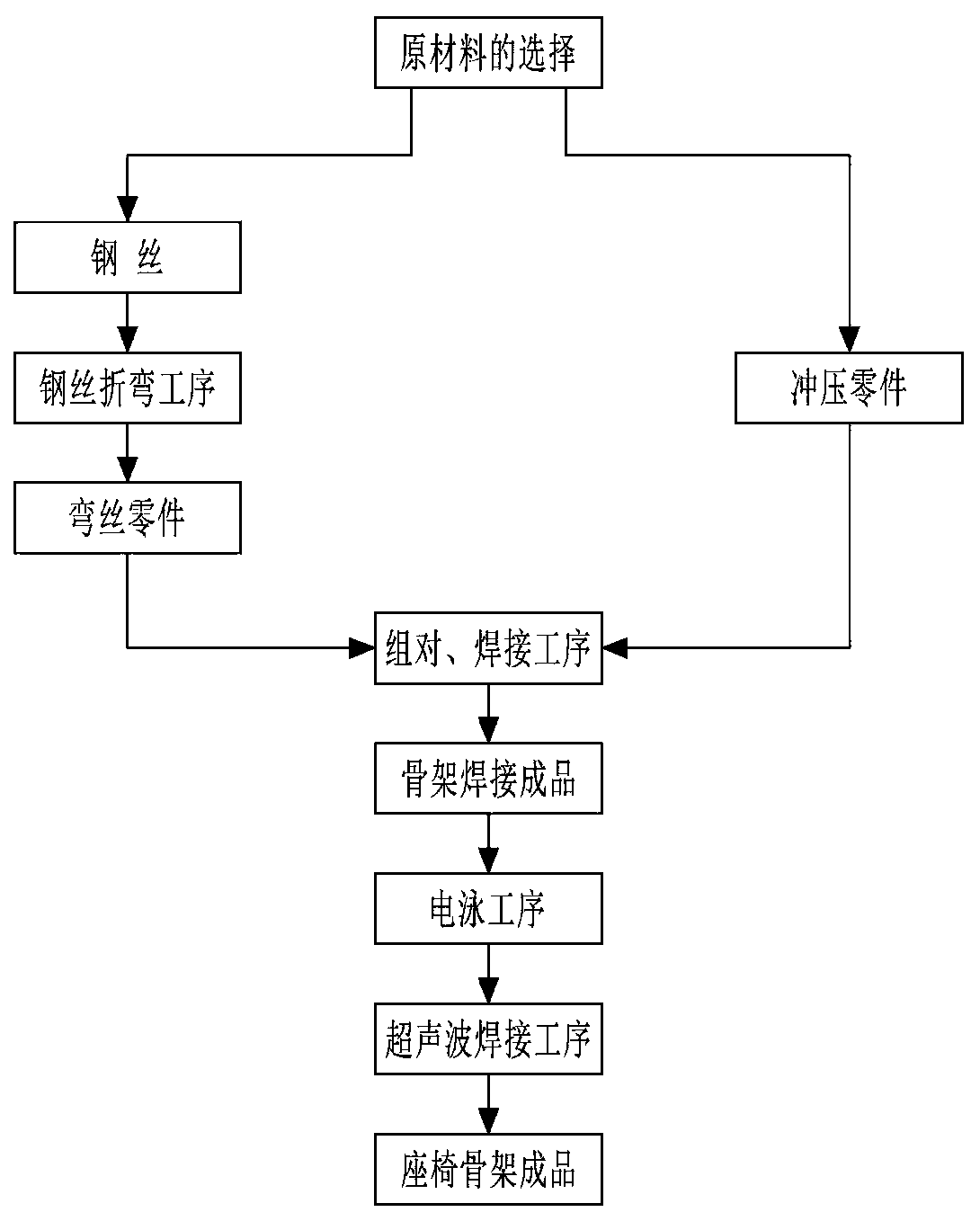

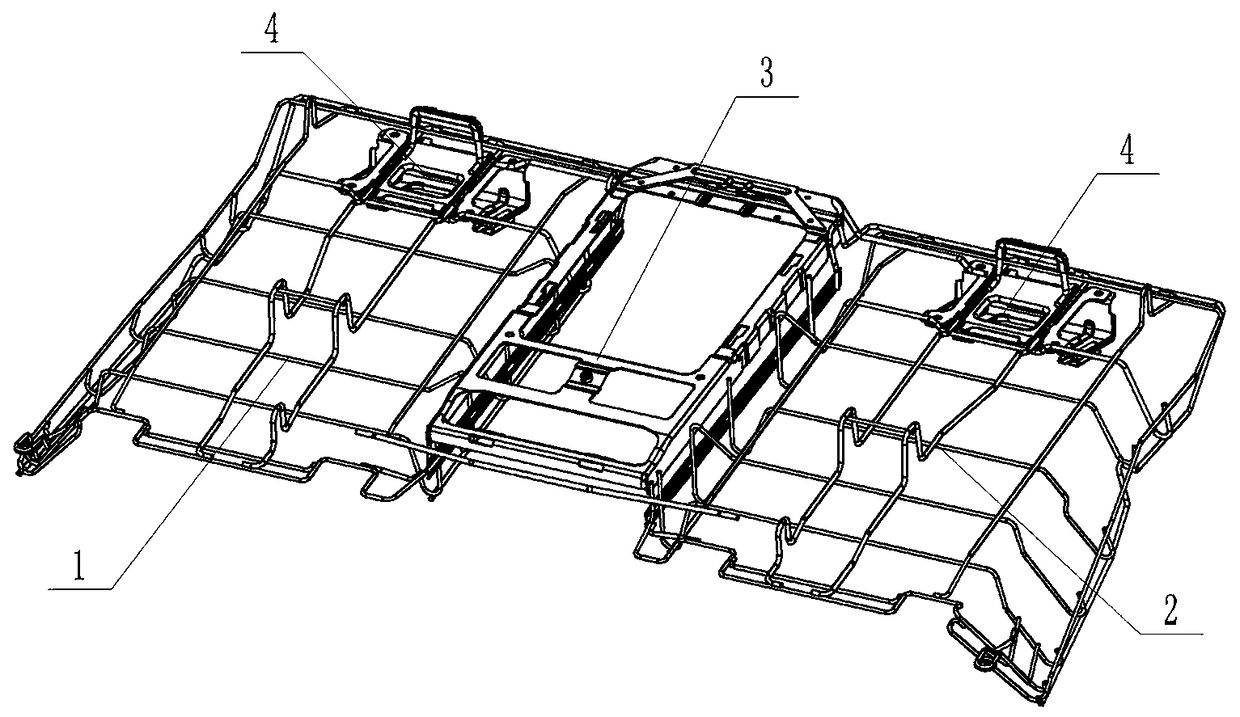

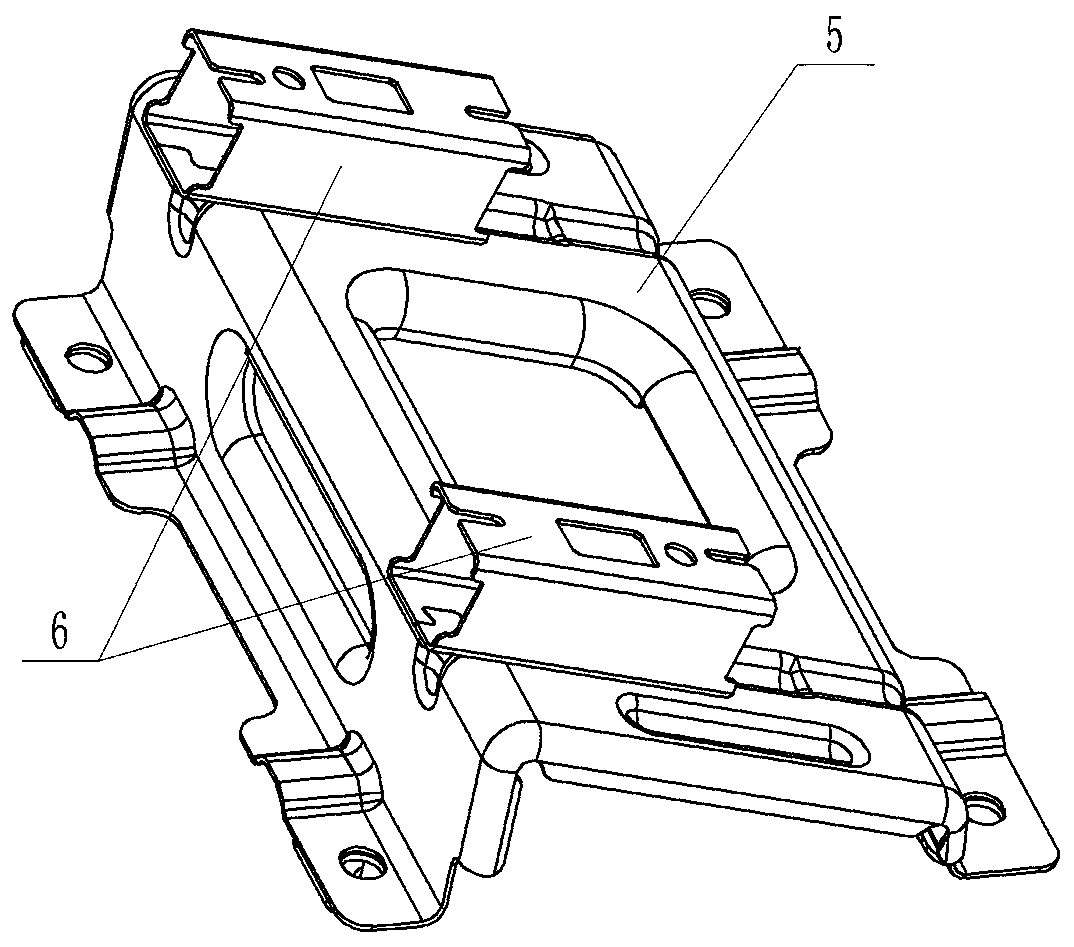

[0034] according to Figure 1-12 The specific steps of the present invention are described in detail. The production process of the automobile seat steel frame includes the following steps: Step 1, selection of steel wire material. The steel wire raw materials for making the steel frame of the seat are high-quality steel wires with diameters of φ4, φ5 and φ6 and high-grade tensile properties (the tensile strength can be as high as 2160MPa). According to specific process requirements, the composition content of the steel wire material can be C: 0.040%, Mn: 0.320%, Si: 0.080%, P: 0.009%, S: 0.004%.

[0035] Step 2. Processing of various wire bending parts. On the B3 and BM30 wire bending machines of Wafos, the steel wire is bent according to the bending shape of the wire bending parts to be produced; to produce various semi-finished wire bending products required for welding the steel frame of the seat. After the first wire bending part is produced, use Aicon's P8 inspection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com