A Combined Die for Making Carbon Fiber Reinforced Wrinkled Sandwich Cylindrical Shell

A combined mold and cylindrical shell technology, which is applied to home appliances, other home appliances, applications, etc., to achieve the effect of controllable quality, simple molding process, and mass industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

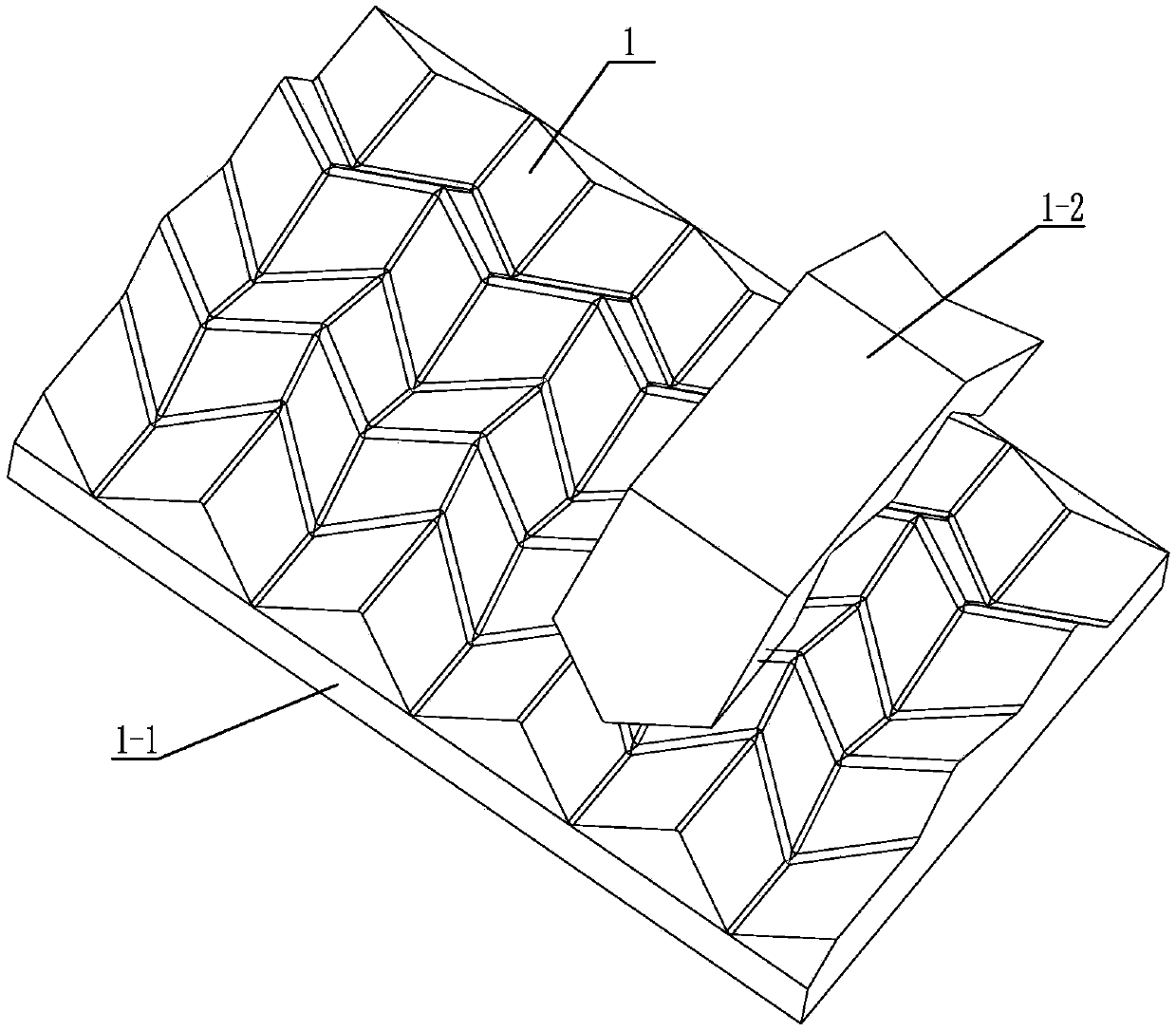

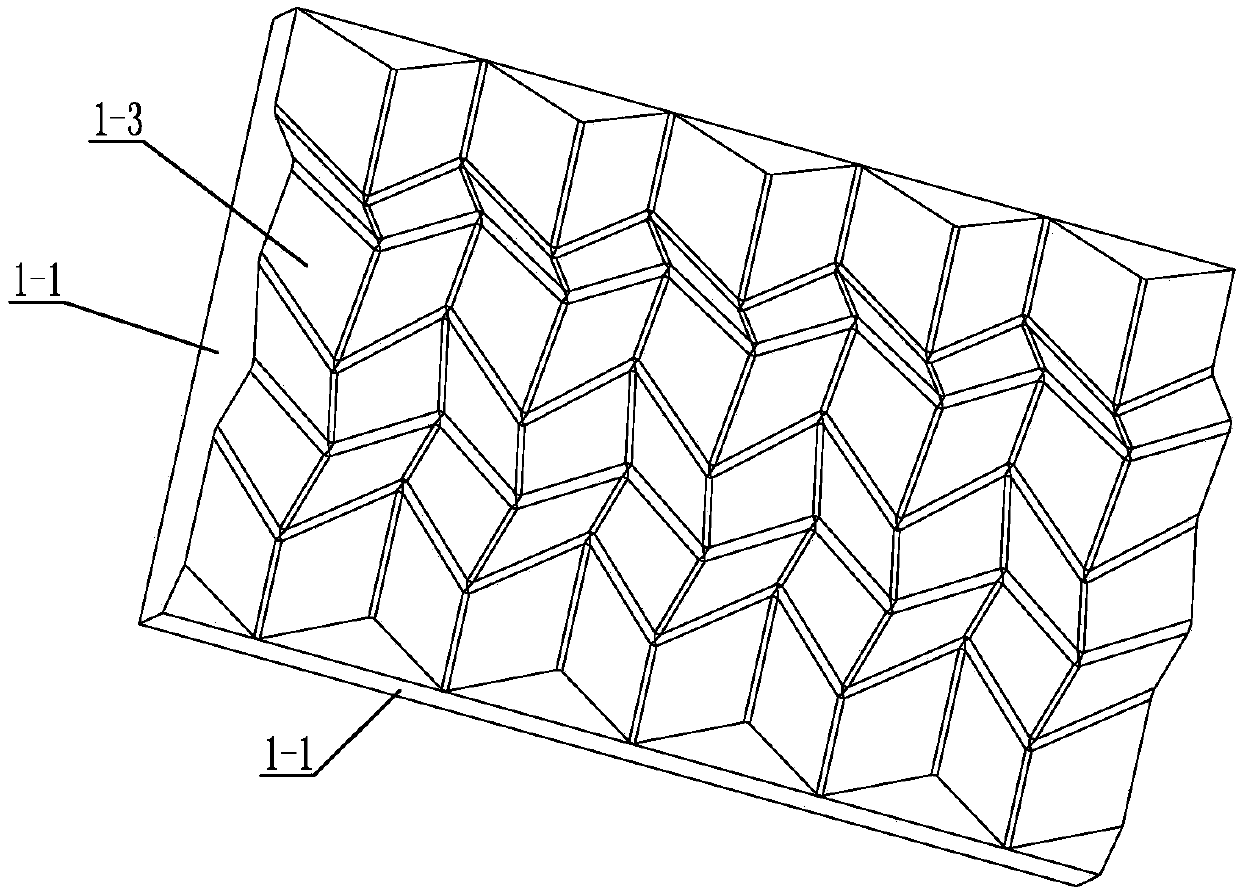

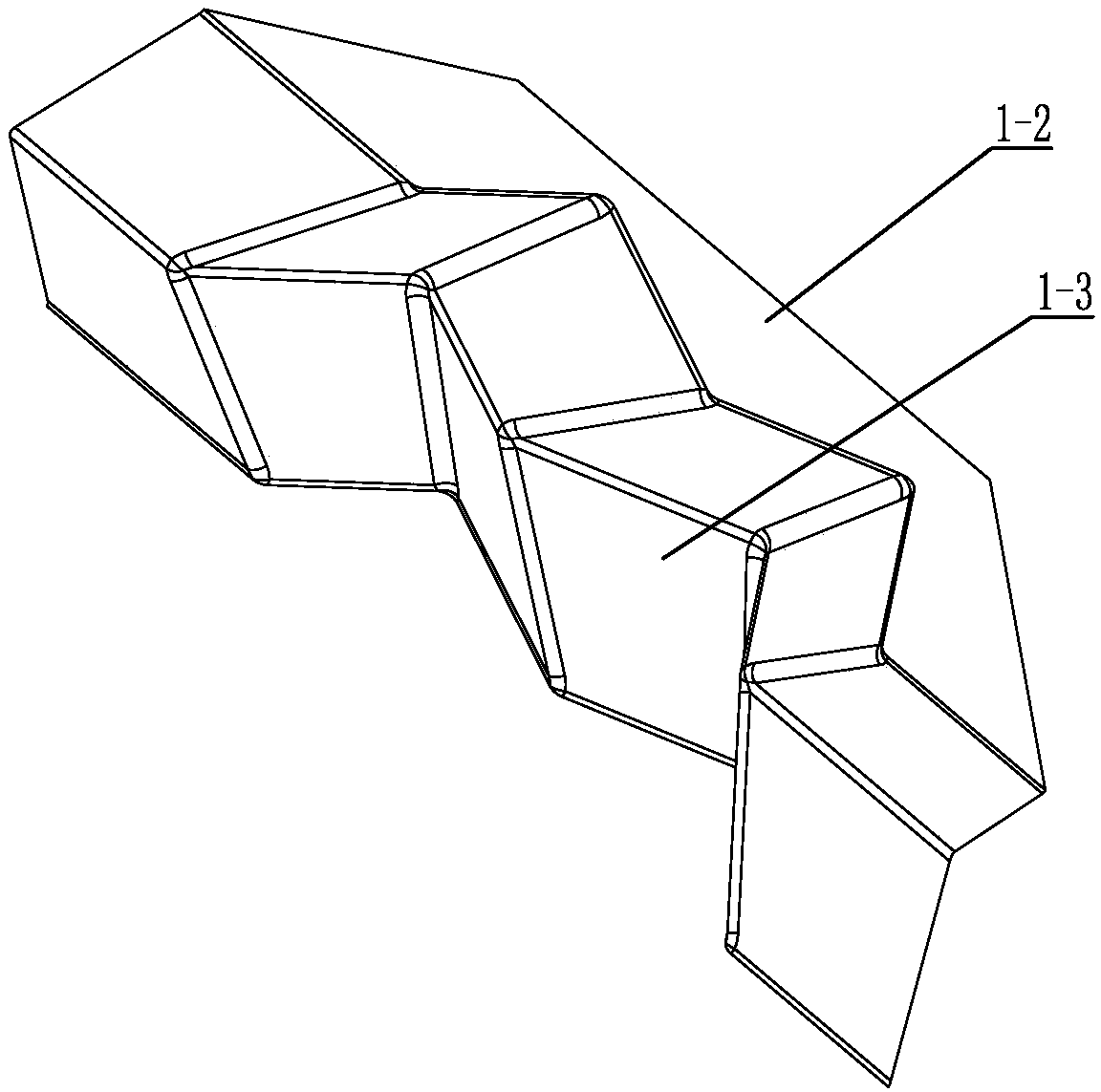

[0027] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this embodiment, this embodiment is to prepare the combination mold of carbon fiber reinforced corrugated sandwich cylindrical shell, this combination mold comprises core molding mold 1, panel molding mold 2 and curing mold 3;

[0028] The core molding die 1 includes a male mold 1-1 and five female molds 1-2, the male mold 1-1 is a quarter ring, and the inner wall of the male mold 1-1 is provided with a plurality of equal quadrilateral units 1-3, multiple quadrilateral units 1-3 are arranged in an array, and multiple quadrilateral units 1-3 are arranged in five along the axial direction of the male mold 1-1, and multiple quadrilateral units 1-3 are arranged along the ring of the male mold 1-1 Set three in the direction, one quadrilateral unit 1-3 in the axial direction of each female mold 1-2, three quadrilateral units 1-3 in the circumferential direction of each female mold 1-2, and five female m...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination figure 2 and Figure 5 This embodiment will be described. In this embodiment, the radius of the inner mold 2-1 is the same as the radius of the inner wall of the male mold 1-1. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 4 Describe this embodiment, this embodiment is that the radius of the inner wall of the middle mold 2-2 is the radius of the inner mold 2-1 plus the thickness of the inner panel prepreg 4, and the radius of the outer wall of the middle mold 2-2 is the same as that of the male mold 1-1. The outer walls have the same radius. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com