Gluing method facilitating plastic film or sheet adhesion exhaustion and application

A technology of plastic film and plastic sheet, applied in the direction of chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of affecting the use effect, low gas release rate, poor air permeability, etc., and achieve the effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

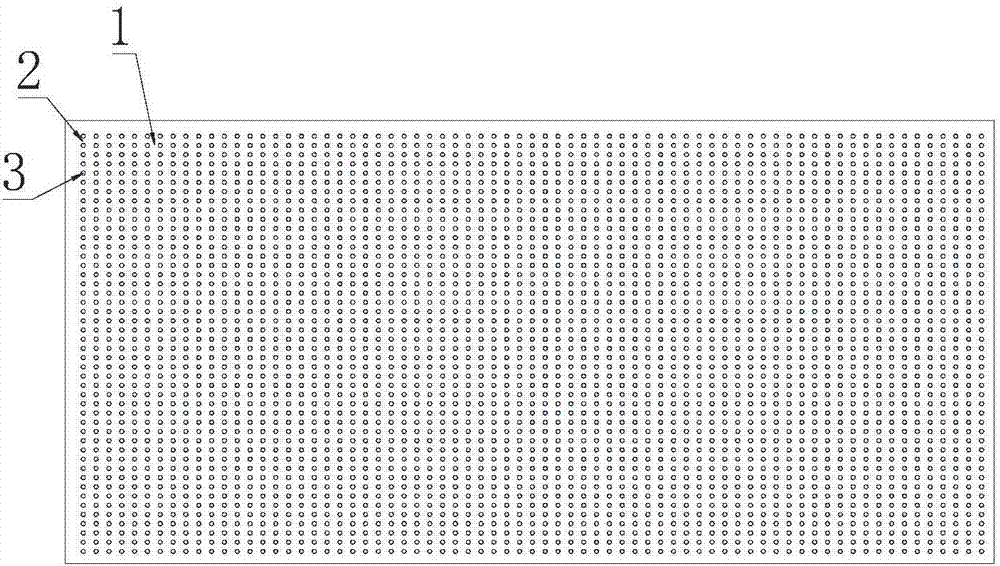

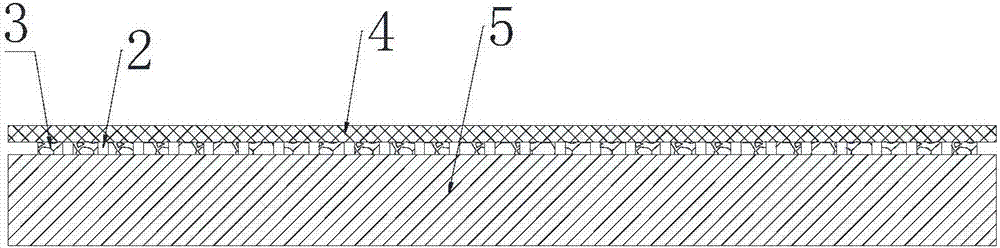

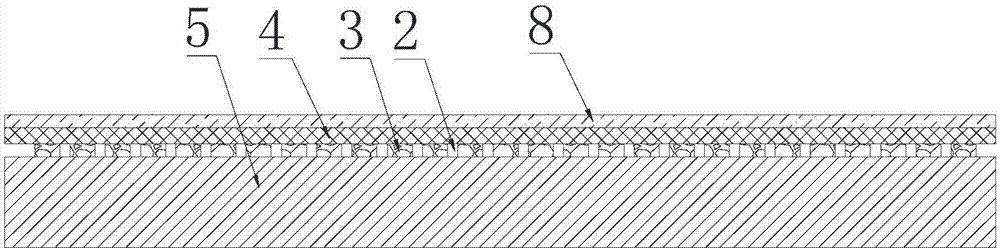

[0027] Such as Figure 1-Figure 3 As shown, the present invention is a kind of gluing method that is beneficial to plastic film or sheet adhesive degassing, and it adopts the mode of dispersed gluing, and viscose is dotted and / or massive and / or linear distribution, makes viscose The joint surface forms a joint-free glue-free channel 1, and the glue-free channel has at least one exhaust port 2; so that during bonding, excess gas is discharged along the glue-free channel under extrusion, and the exhaust port of the channel Keep it open, even if the plastic sheet or plastic film is laminated with PS foam board, PVC foam board, EVA foam board, PE foam board and other boards that release gas for a long time with a large gas content, the board and plastic sheet or plastic The gas between the membranes cannot accumulate, and it can be discharged in time to completely solve the problem of bubbling, which greatly facilitates the production. In this embodiment, the viscose adopts the f...

Embodiment 2

[0029] Such as Figure 4 As shown, in this embodiment, the viscose is coated in a block-like manner, and there is a gap between two adjacent blocks of viscose, so that multiple layers are formed between the plastic film or plastic sheet and the ply as the base material. The gas channels 6 that connect with each other. The blocky viscose 7 is a tapered structure with a narrow top and a wide bottom, which increases the area of the gas passage and makes the exhaust more fluent.

Embodiment 3

[0031] In this embodiment, the viscose is compounded by point coating and block coating, between two adjacent point viscose, between two block viscose or between point viscose and block viscose There are gaps, so that a plurality of intersecting and communicating gas passages are formed between the plastic film or plastic sheet and the plate layer as the base material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com