Cylindrical air intake and exhaust device and internal combustion engine cylinder cover

A technology for intake and exhaust and internal combustion engines, applied to valve devices, cylinder heads, engine sealing devices, etc., can solve problems such as reducing the stroke of work, and achieve the effects of reducing energy, reducing weight, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

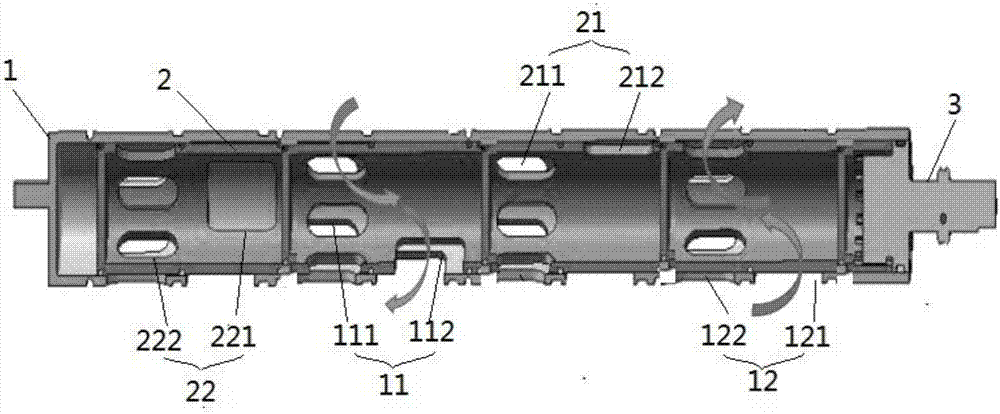

[0053] Such as figure 1 As shown, this embodiment provides a cylinder-type air intake and exhaust device, which includes an outer cylinder 1 , an inner cylinder 2 and a drive shaft 3 . The outer cylinder 1 is cylindrical with one end open, and the outer cylinder 1 is provided with an outer cylinder air intake hole group 11 and an outer cylinder exhaust hole group 12 . The inner cylinder 2 is cylindrical and is rotatably installed in the cavity of the outer cylinder 1. The inner cylinder 2 can be loaded into the outer cylinder 1 from the open end of the outer cylinder 1. The inner cylinder 2 is provided with an inner cylinder air inlet group 21 and an inner cylinder. Barrel vent group 22. The drive shaft 3 is connected to the inner cylinder 3 to drive the inner cylinder 3 to rotate. This structure can significantly reduce the size and weight of the entire internal combustion engine.

[0054] The sweeping surface of the air intake hole group 21 of the inner cylinder overlaps ...

Embodiment 2

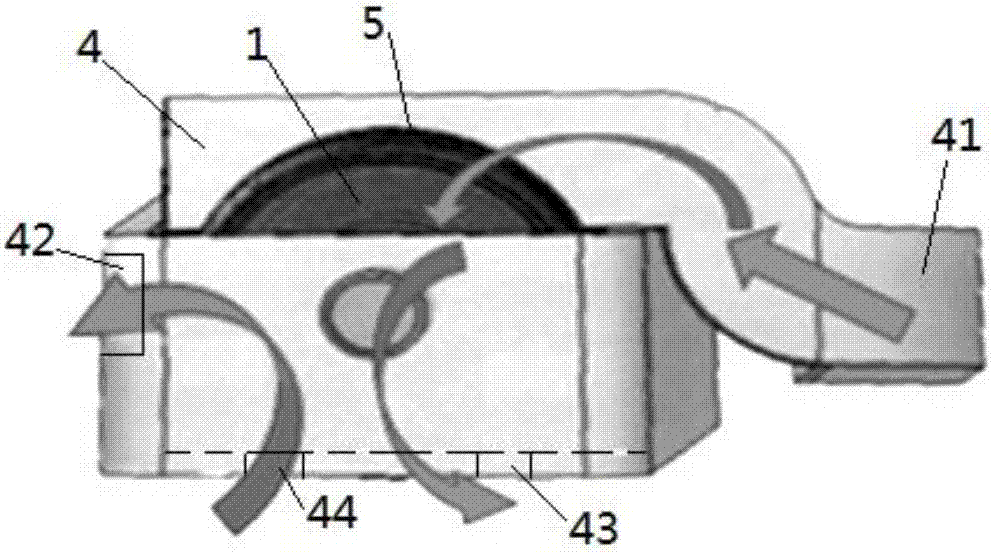

[0070] For larger internal combustion engines, such as diesel engines, in order to facilitate manufacturing and installation, such as Figure 8 As shown, the cover body 4 can be made separately, and the cover body is divided into an upper cover 45 and a lower cover 46. When assembling, the upper cover 45 and the lower cover 46 are fixedly connected by bolts. The intake part and the exhaust part of the internal combustion engine can also be provided separately, and the upper cover 45 is provided with the semicircular groove 511 of the intake and the semicircular groove 521 of the exhaust, and the lower cover 46 is provided with the semicircular groove 521 of the intake. Shaped groove 512 and semicircular groove 522 for exhaust. After the upper cover 45 and the lower cover 46 are combined, the semicircular groove 511 and the semicircular groove 512 form the intake cavity 51 , and the semicircular groove 512 and the semicircular groove 522 form the exhaust cavity 52 . The intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com