Universal fuel engine

An engine and fuel technology, used in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of high moisture content, poor stability, and particulate impurities, and achieve the reduction of harmful substances, the improvement of combustion rate, and the improvement of combustion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

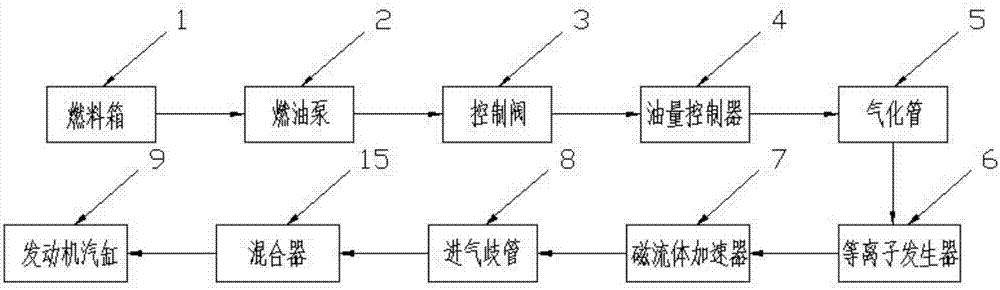

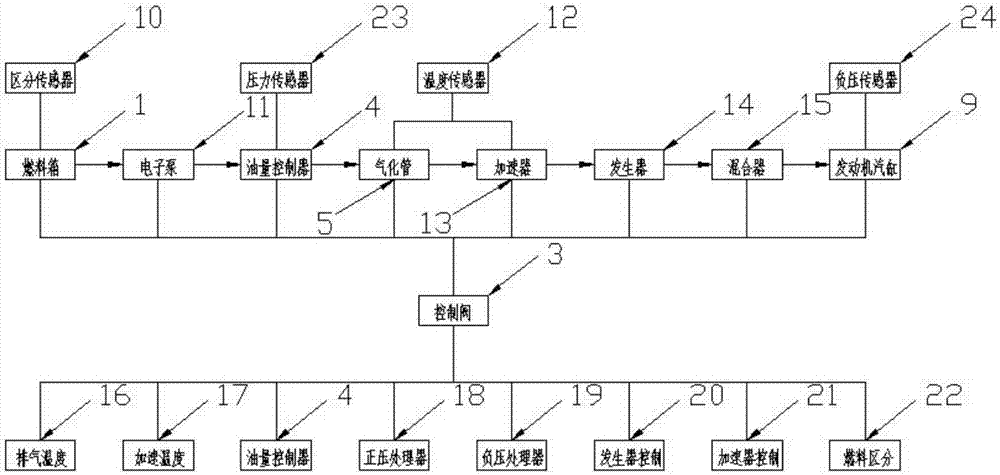

[0024] Such as Figure 1-2 As shown, a universal fuel engine includes a fuel tank 1 and a fuel pump 2 connected to the fuel tank 1 through an oil pipe, the fuel pump 2 is connected to the control valve 3 through a line, and the control valve 3 is connected to the gasification pipe 5 through the fuel quantity controller 4, The fuel pump 2 is connected to the gasification pipe 5 through the oil pipe, and the gasification pipe 5 is connected with a plasma generator 6 and an intake manifold 8, and the plasma generator 6 is connected with a magnetic fluid accelerator 7, and the plasma generator 6 and the intake manifold 8 Both are connected to the mixer 15 through pipelines, and the mixer 15 is connected to the engine cylinder 9;

[0025] The signal input end of the control valve 3 is respectively connected with the fuel tank 1, the gasification pipe 5, the engine cylinder 9, the electronic pump 11, the fuel quantity controller 4, the accelerator 13, the generator 14 and the mixer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com