Aromatic heterocyclic derivative, and organic electroluminescent element, illumination device, and display device using aromatic heterocyclic derivative

An electroluminescence element and aromatic heterocycle technology, applied in the field of aromatic heterocycle derivatives, can solve the problems of incompleteness and poor thermal stability of organic EL elements, etc., and achieve the effect of long luminous life and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0632] "Manufacturing of Organic EL Devices"

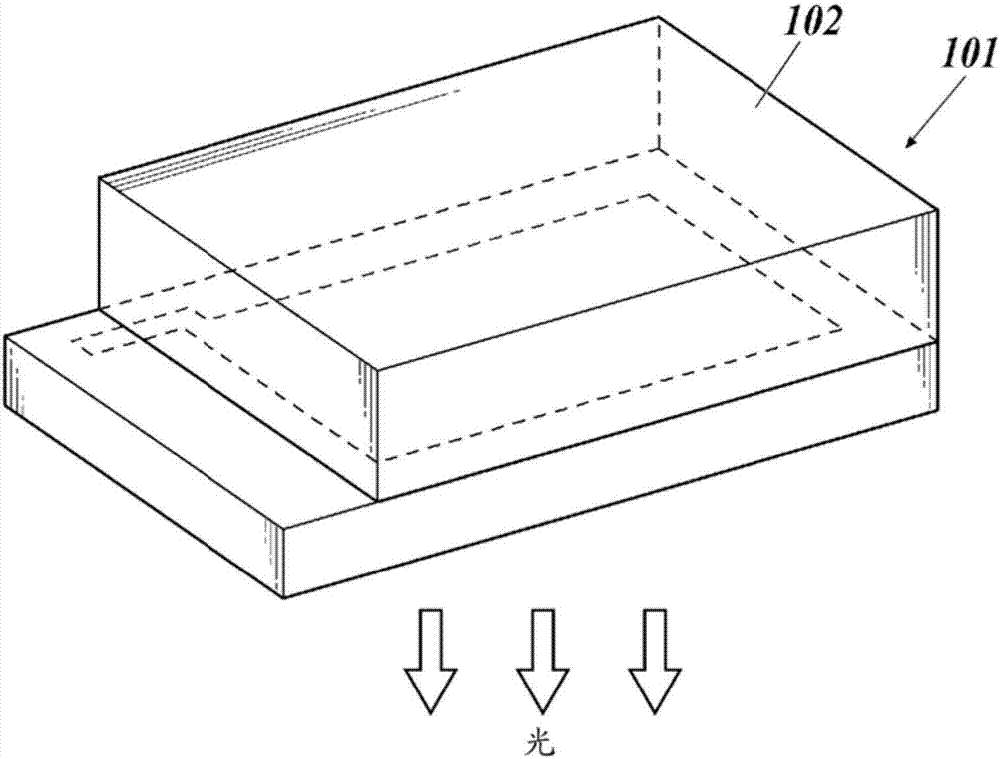

[0633] (1) Fabrication of the organic EL element 101

[0634] Form a film of ITO (indium tin oxide) with a thickness of 150 nm as an anode on a glass substrate of 50 mm × 50 mm and a thickness of 0.7 mm, and pattern it, and then use isopropyl alcohol to treat the transparent substrate with the ITO transparent electrode. After ultrasonic cleaning, drying with dry nitrogen gas, and UV ozone cleaning for 5 minutes, the transparent substrate was fixed on a substrate holder of a commercially available vacuum evaporation device.

[0635] Each resistive heating boat for vapor deposition in the vacuum vapor deposition apparatus is filled with the constituent materials of each layer in an optimum amount for manufacturing each element. The resistance heating boat is made of molybdenum or tungsten.

[0636] Decompress to vacuum degree 1×10 -4 After Pa, the resistance heating boat containing HI-1 was energized and heated, and deposited on ...

Embodiment 2

[0663] "Manufacturing of Organic EL Devices"

[0664] (1) Fabrication of the organic EL element 201

[0665] Form an ITO (indium tin oxide) film with a thickness of 150 nm on a glass substrate of 50 mm x 50 mm and a thickness of 0.7 mm as an anode, and after patterning, clean the transparent substrate with the ITO transparent electrode with isopropanol ultrasonically , dried with dry nitrogen, and after UV ozone cleaning was performed for 5 minutes, the transparent substrate was fixed on a substrate holder of a commercially available vacuum evaporation device.

[0666] Each resistive heating boat for vapor deposition in the vacuum vapor deposition apparatus is filled with the constituent materials of each layer in an optimum amount for manufacturing each element. The resistance heating boat is made of molybdenum or tungsten.

[0667] Decompress to vacuum degree 1×10 -4 After Pa, the resistance heating boat containing HI-2 was energized and heated, and deposited on the ITO t...

Embodiment 3

[0684] "Manufacturing of Organic EL Devices"

[0685] (1) Fabrication of the organic EL element 301

[0686] Form an ITO (indium tin oxide) film with a thickness of 150 nm on a glass substrate of 50 mm x 50 mm and a thickness of 0.7 mm as an anode, and after patterning, clean the transparent substrate with the ITO transparent electrode with isopropanol ultrasonically , dried with dry nitrogen, and after UV ozone cleaning was performed for 5 minutes, the transparent substrate was fixed on a substrate holder of a commercially available vacuum evaporation device.

[0687] Each resistive heating boat for vapor deposition in the vacuum vapor deposition apparatus is filled with the constituent materials of each layer in an optimum amount for manufacturing each element. The resistance heating boat is made of molybdenum or tungsten.

[0688] Decompress to vacuum degree 1×10 -4 After Pa, the resistance heating boat containing HI-2 was energized and heated, and deposited on the ITO t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| optical properties | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com