Method for melting and solidifying heavy metal in waste burning fly ash

A technology of waste burning, melting and solidification, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as non-reporting, and achieve the effect of good control of heavy metal leaching effect and obvious effect of heavy metal solidification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

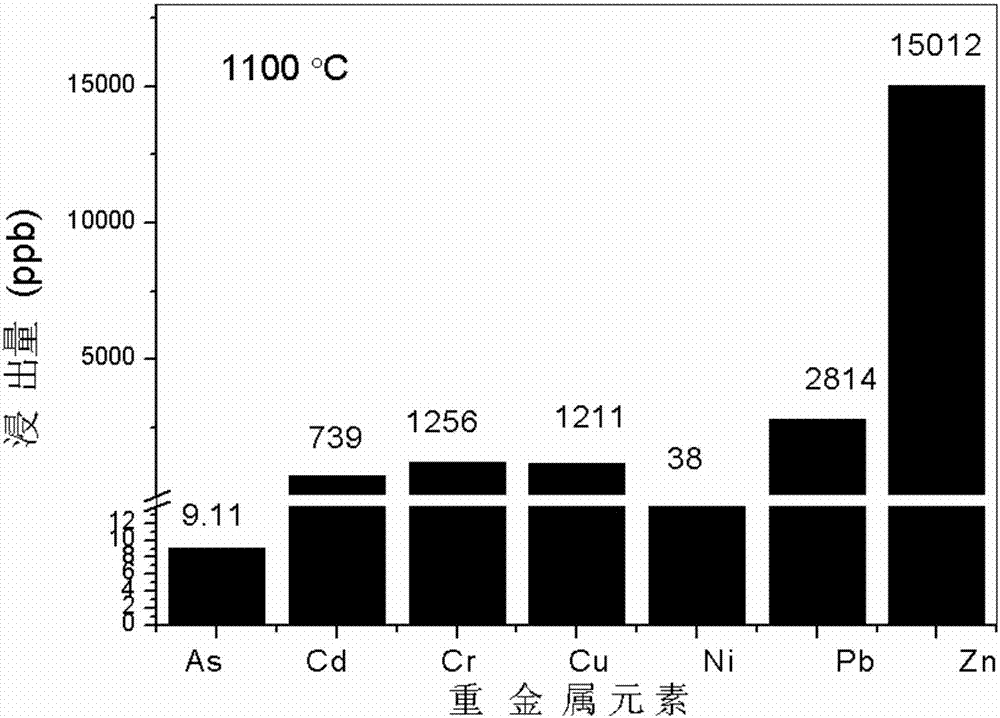

[0018] Take 10g of blast furnace gas mud and 90g of waste combustion fly ash for grinding to achieve thorough mixing, then put it into a tube furnace, raise the temperature to 800°C, and keep it warm for 0.5 hours. Finally, for the solidified product, As, Cd, Cr, Cu , Ni, Pd and Zn heavy metal leaching detection.

Embodiment 2

[0020] Take 20g of blast furnace gas mud and 80g of waste combustion fly ash and grind them to achieve thorough mixing, then put them into a tube furnace, raise the temperature to 900°C, and keep it warm for 1 hour. , Ni, Pd and Zn heavy metal leaching detection.

Embodiment 3

[0022] Take 30g of blast furnace gas mud and 70g of waste combustion fly ash for grinding to achieve full mixing, then put it into a tube furnace, raise the temperature to 1000°C, keep it warm for 1.5 hours, and finally carry out As, Cd, Cr, Cu for the solidified product according to national standards , Ni, Pd and Zn heavy metal leaching detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com