Compound trussed movable overload casting robot

A truss-type, robotic technology, applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of high labor intensity, limited movement, and small operating range of workers, so as to reduce labor intensity and production costs, and improve support stability Sexuality, the effect of improving motor flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

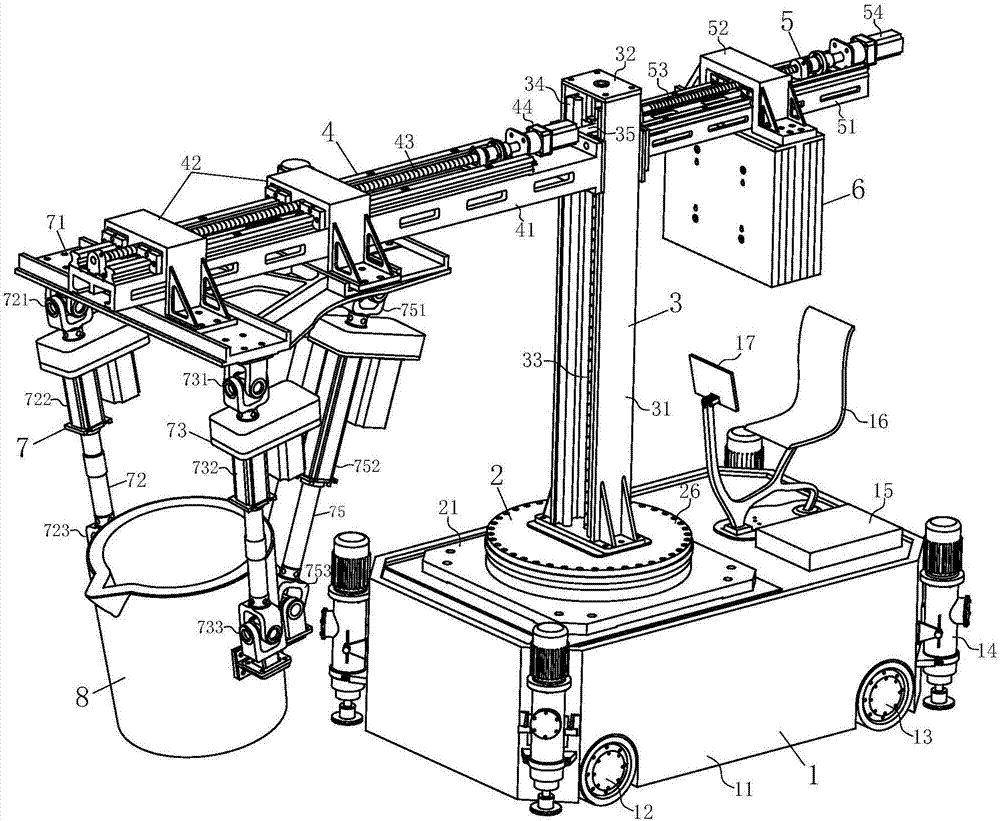

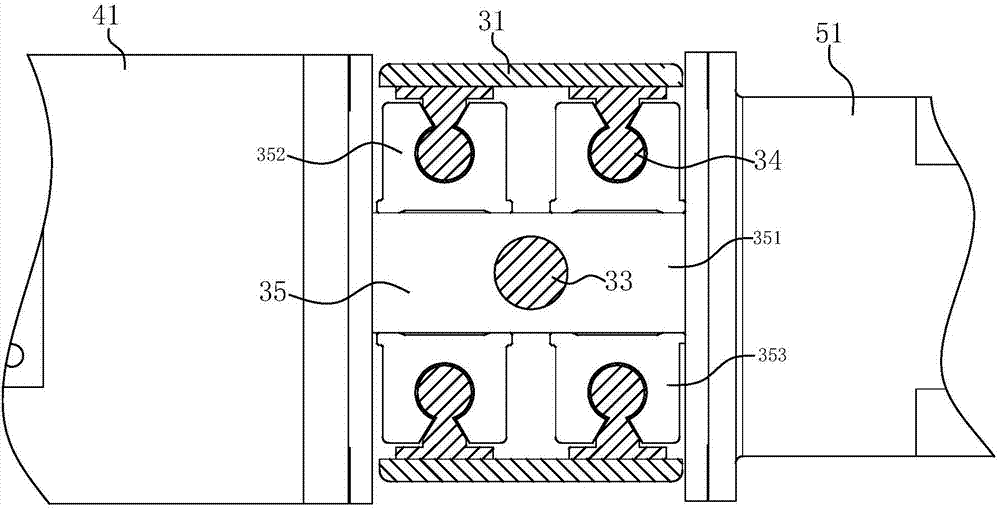

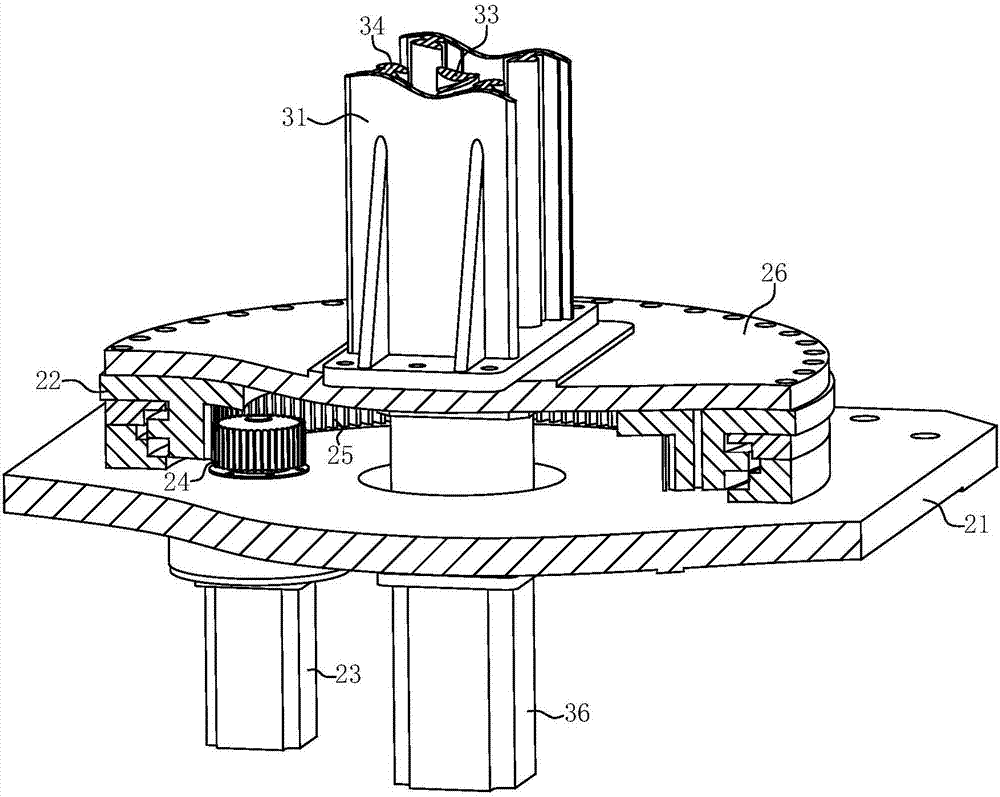

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a hybrid truss-type mobile heavy-duty casting robot includes a four-wheel-drive wheeled mobile platform 1, a slewing device 2, a lifting device 3, a forward moving device 4, a rearward moving device 5, a counterweight device 6, and a parallel working arm 7 and end effector 8 . Wherein, the four-wheel-drive wheeled mobile platform 1 is a carrying and mobile platform of the present invention, including a platform frame 11, a front drive wheel 12, a rear drive wheel 13, a self-balancing hydraulic support leg 14, a controller 15 and a monitor 17. The bottoms of the front and rear ends of the platform frame 11 are provided with navigation sensors, and the navigation sensors adopt magnetic navigation sensors or laser scanners or infrared emitters or ultrasonic emitters; at the front of the platform frame 11 The side, the rear side, the left side and the middle of the right side are provided wit...

specific Embodiment approach 2

[0038] Such as figure 1 with Figure 4 As shown, the first branch chain 72 includes a first upper universal joint 721 , a first telescopic group 722 and a first lower universal joint 723 . Wherein, the upper end of the first upper universal joint 721 is fixedly connected with the top fixed platform 71, the upper end of the first telescopic group 722 is fixedly connected with the lower end of the first upper universal joint 721, and the first upper universal joint 721 is fixedly connected. The lower end of the telescopic group 722 is fixedly connected with the upper end of the first lower universal joint 723 , and the lower end of the first lower universal joint 723 is fixedly connected with the end effector 8 . The second branch chain 73 includes a second upper universal joint 731, a second telescopic group 732 and a second lower universal joint 733, and the third branch chain 74 includes a third upper universal joint 741, a third telescopic group 742 and a third The lower u...

specific Embodiment approach 3

[0039] Such as figure 1 with image 3 As shown, the rotary motor 23 in this embodiment adopts a servo geared motor. With this design, the DC servo motor has a high speed, and the corresponding RV precision reducer can provide a large torque; in addition, the DC servo motor can also realize closed-loop control, which can achieve high transmission accuracy. Other compositions and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com