Evaporation equipment for flexible OLED and process of evaporation equipment

A flexible and evaporation technology, which is applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problems of waste materials, cavity pollution, and low uniformity of workpieces, so as to avoid waste materials, Avoid the effect of air molecular impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

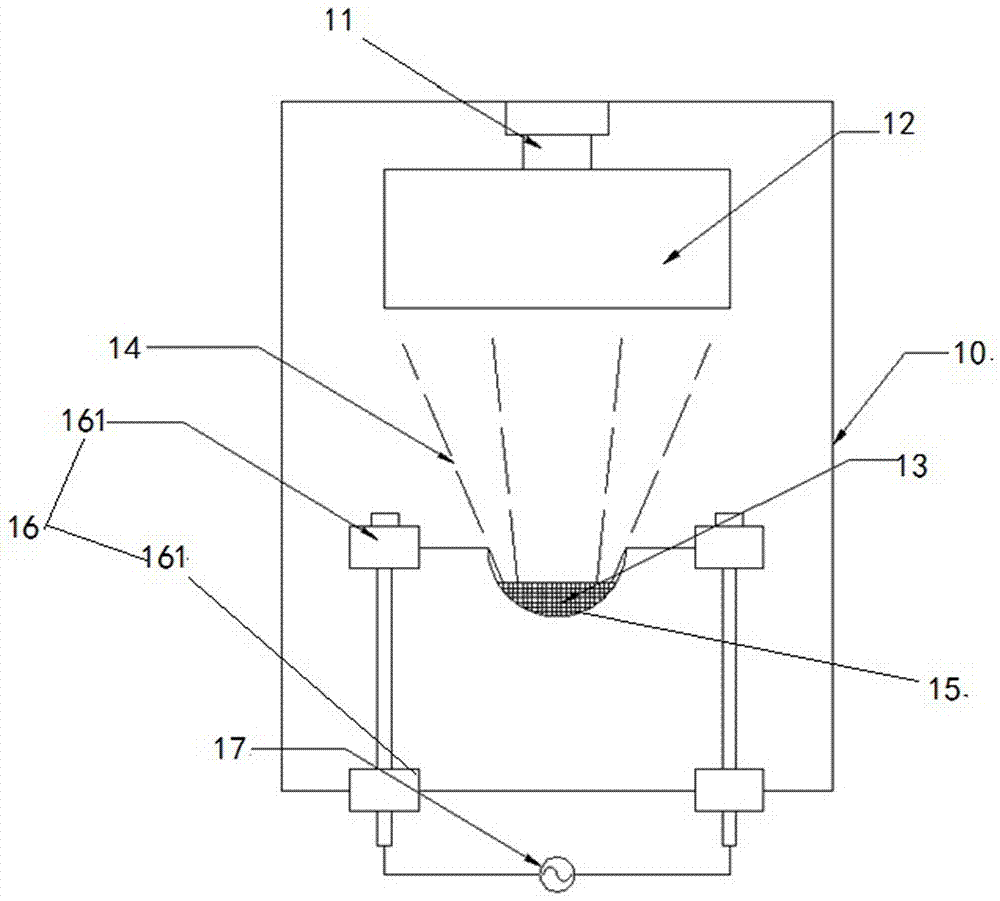

[0024] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0025] see figure 1 The evaporation equipment of the flexible OLED provided by the present invention comprises a vacuum evaporation chamber 10, a rotating shaft 11 installed on the top of the vacuum evaporation chamber and a substrate 12 fixed on the rotating shaft; Place the container 15 of the plating material 13, the container is located directly below the substrate, the container is electrically connected to the heating device 16, and the heating device is electrically connected to the power supply 17;

[0026] The plating material is placed in a heat-controllable container generated by a heating device, and the container is heated by starting a power supply to generate heat energy; the plating material is heated to form a plating material vapor 14, and the plating material vapor is free to move in a straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com