Multi-functional heat pump drying device

A technology of heat pump drying and heat pump device, applied in drying, heat pump, dryer and other directions, can solve the problems of low drying efficiency, defective adaptability, uneconomical energy consumption cost of condensation and dehumidification, etc., to achieve easy product operation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

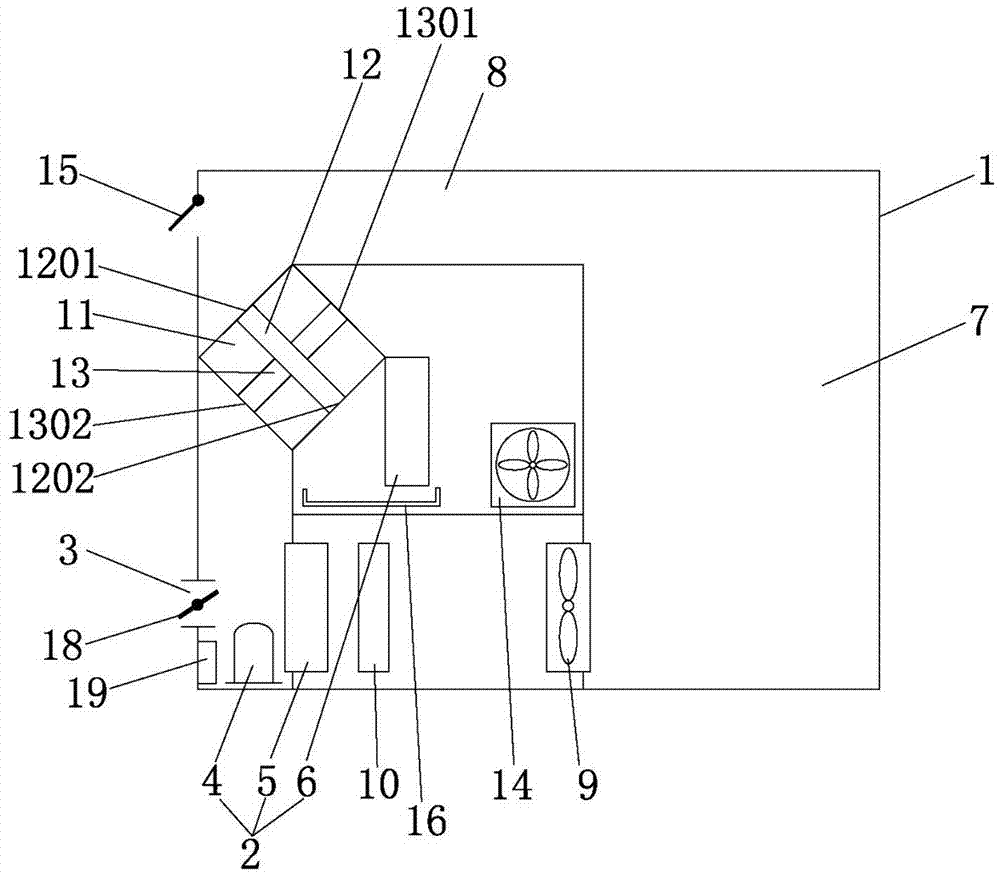

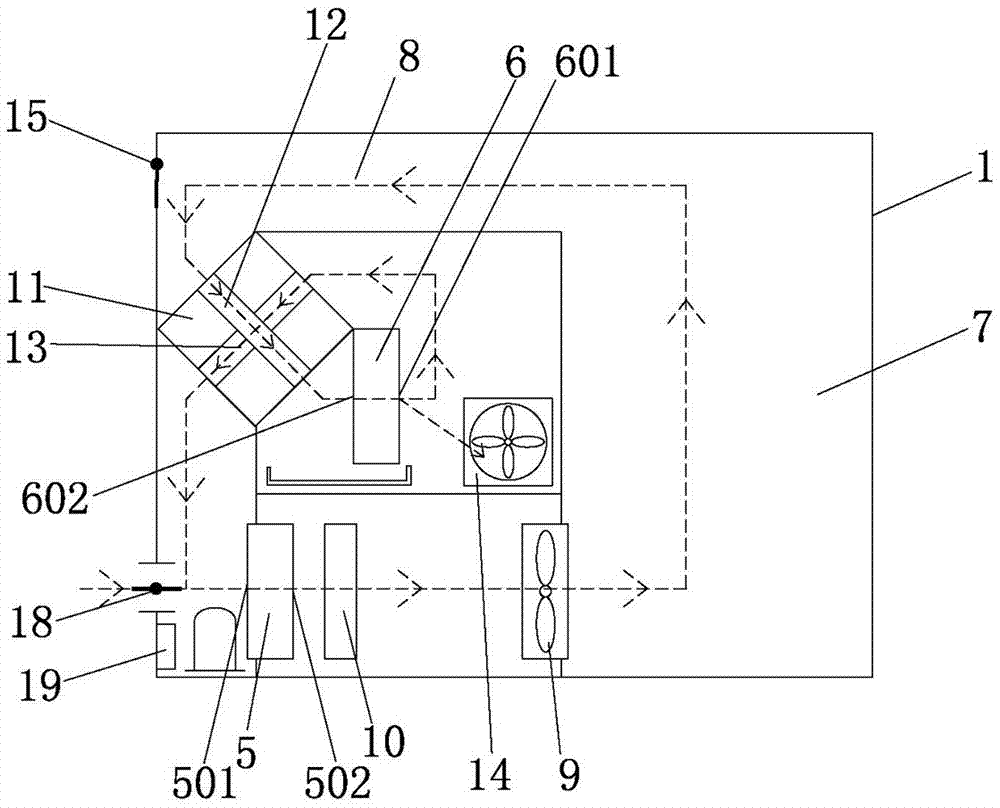

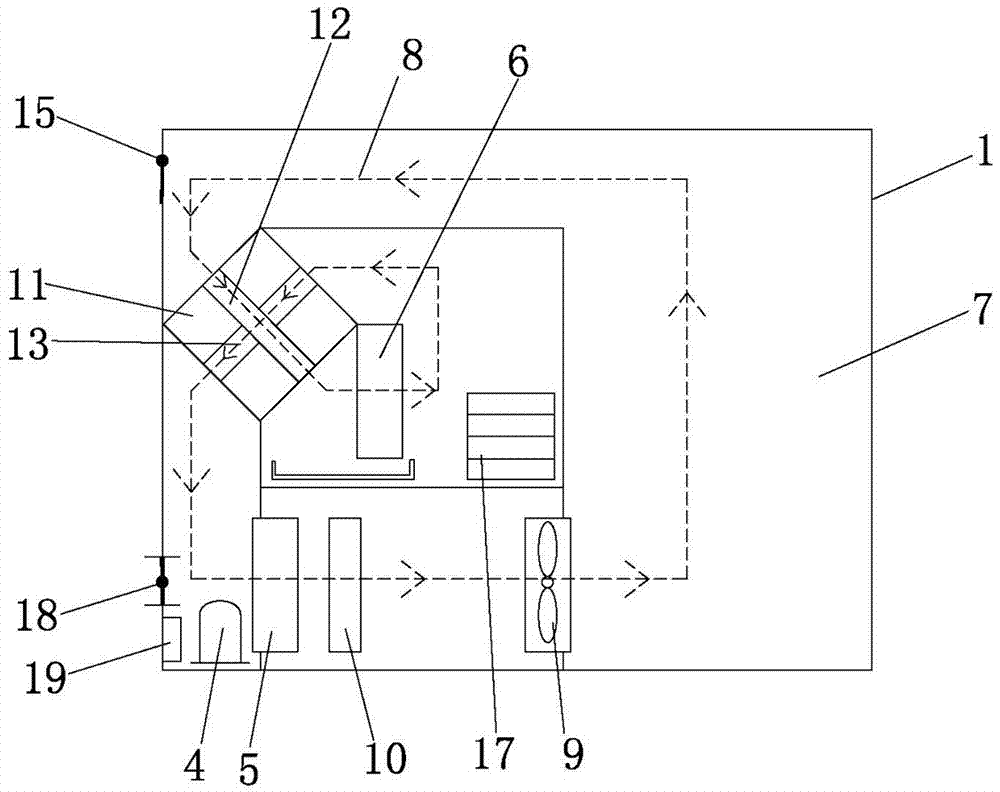

[0029] Such as figure 1 As shown, a multifunctional heat pump drying device includes a drying chamber 1 and a heat pump device 2. The drying chamber 1 is provided with a fresh air inlet 3, and the heat pump device 2 includes a compressor 4, a condenser 5 and an evaporator 6. The The drying chamber 1 is provided with a drying area 7 and a return air area 8, the air inlet end 501 of the condenser 5 is adjacent to the fresh air inlet 3, and the air outlet end 502 of the condenser 5 is connected to the drying area through the internal circulation fan 9. 7 is connected, and an electric heater 10 is installed between the condenser 5 and the internal circulation fan 9;

[0030] The role of the electric heater is to provide auxiliary heat supply during the cold start stage to speed up the temperature rise. It is a backup heat source, especially suitable for us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com