Gum-dipped glove production process

A production process and glove technology, which is applied in gloves, clothing, applications, etc., can solve the problems of unfavorable health of workers, liver function damage, environmental pollution, etc., and achieve the goal of increasing wear resistance, increasing adhesion, and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

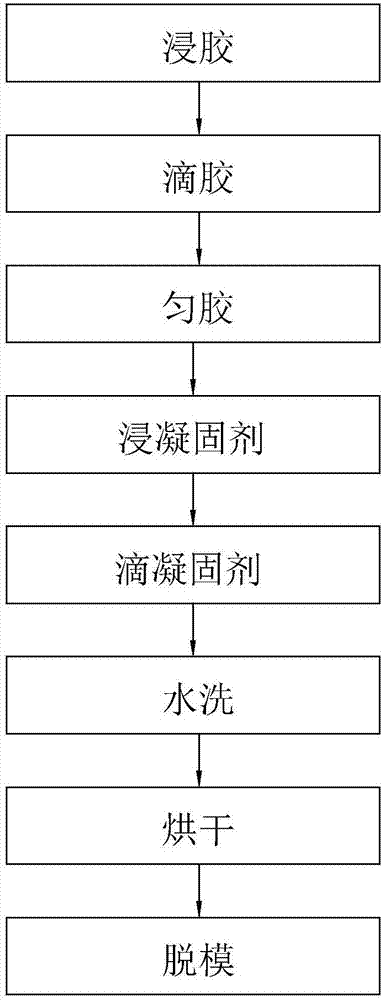

[0047] Embodiment 1: as figure 1 Shown, a kind of dipped gloves production technique comprises the steps:

[0048] a. Glue dipping: Put the gloves to be dipped on the hand model, and immerse the palm of the glove on the hand model in the water-based PU glue at room temperature, and the dipping time is 1 second;

[0049] b. Glue dispensing: Lift the hand model into the air to make the excess water-based PU glue drip clean, and the dispensing time is 40 seconds;

[0050] c. Uniform glue: Make the hand mold rotate 360 degrees, so that the water-based PU glue is evenly distributed on the surface of the palm of the glove, and the glue uniform time is 25 seconds;

[0051] d, soaking coagulant: immerse the gloves in the step c in the coagulant, and the soaking time of the coagulant is 2 minutes;

[0052] e. Dropping coagulant: Lift the hand model into the air to make the excess coagulant drip clean, and the time for dripping the coagulant is 2 minutes;

[0053] f. Water washing:...

Embodiment 2-12

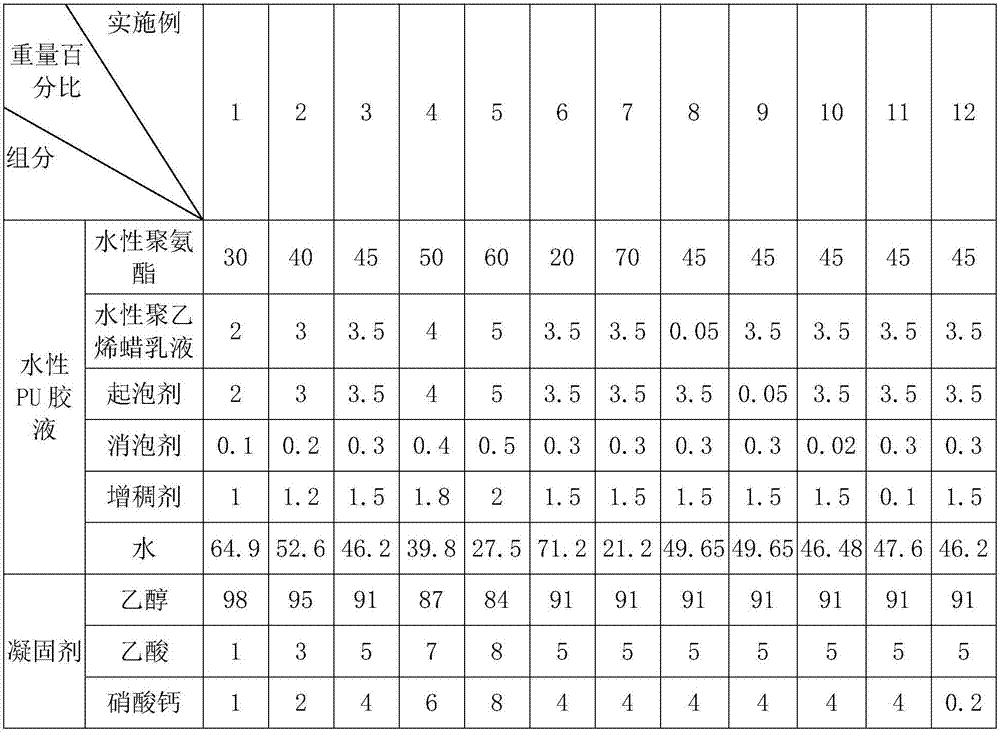

[0057] Example 2-12: A production process for dipped gloves, the difference from Example 1 is that the components and weight percentages of the water-based PU glue and coagulant are shown in Table 1.

[0058] Each component of water-based PU glue and coagulant and its weight percent in the embodiment 1-12 of table 1

[0059]

Embodiment 13

[0060] Embodiment 13: A production process of dipped gloves, the difference from Example 3 is that the dipping time in step a is 2 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com