Full-sealing dry-type separation process for fine-sized magnetite

A fully sealed, magnetite technology, applied in the field of mineral processing, can solve the problems of rising grinding cost, waste of resources, small difference in specific gravity between surrounding rock and magnetite, etc., to reduce grinding cost, avoid resource waste, pre-selection high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

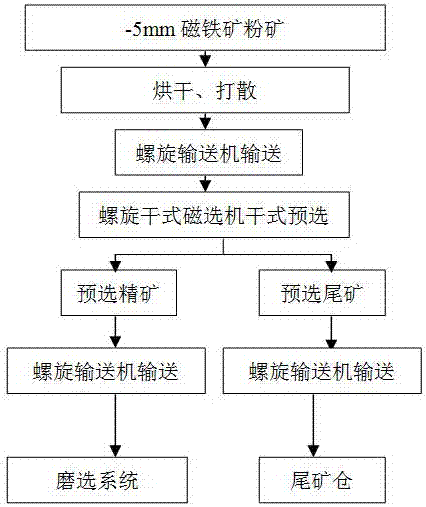

[0010] The fully-sealed dry-type discarding process of the magnetite powder ore with a grade of 32% in Jiuzi Iron and Steel Group includes the following steps:

[0011] A. Screen -5mm magnetite powder ore from the crushed magnetite ore. After drying and breaking up, it is sent to the screw dry magnetic separator by the screw conveyor for fully sealed dry pre-selection and discarding operation. The yield and grade are controlled by the speed of the spiral dry magnetic separator, and the pre-selected tailings with a discarding yield of 10% and a discarding grade of 3% are obtained. Through the dry selection test of the magnetite laboratory after discarding, the waste rock containing only It is 0.2%, and the tailings grade of dry pre-selection meets the requirements of qualified tailings grade.

[0012] B. After fully sealed dry pre-selection, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com