High-strength suspended single hydraulic prop with stainless steel sleeve and sleeve layer composite method

A single hydraulic prop, stainless steel sleeve technology, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of loss of inlaid layer, damage of inlaid layer, stainless steel sleeve detachment, etc., to eliminate economic costs and enhance fracture resistance. ability, enhance the effect of anti-cannon collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

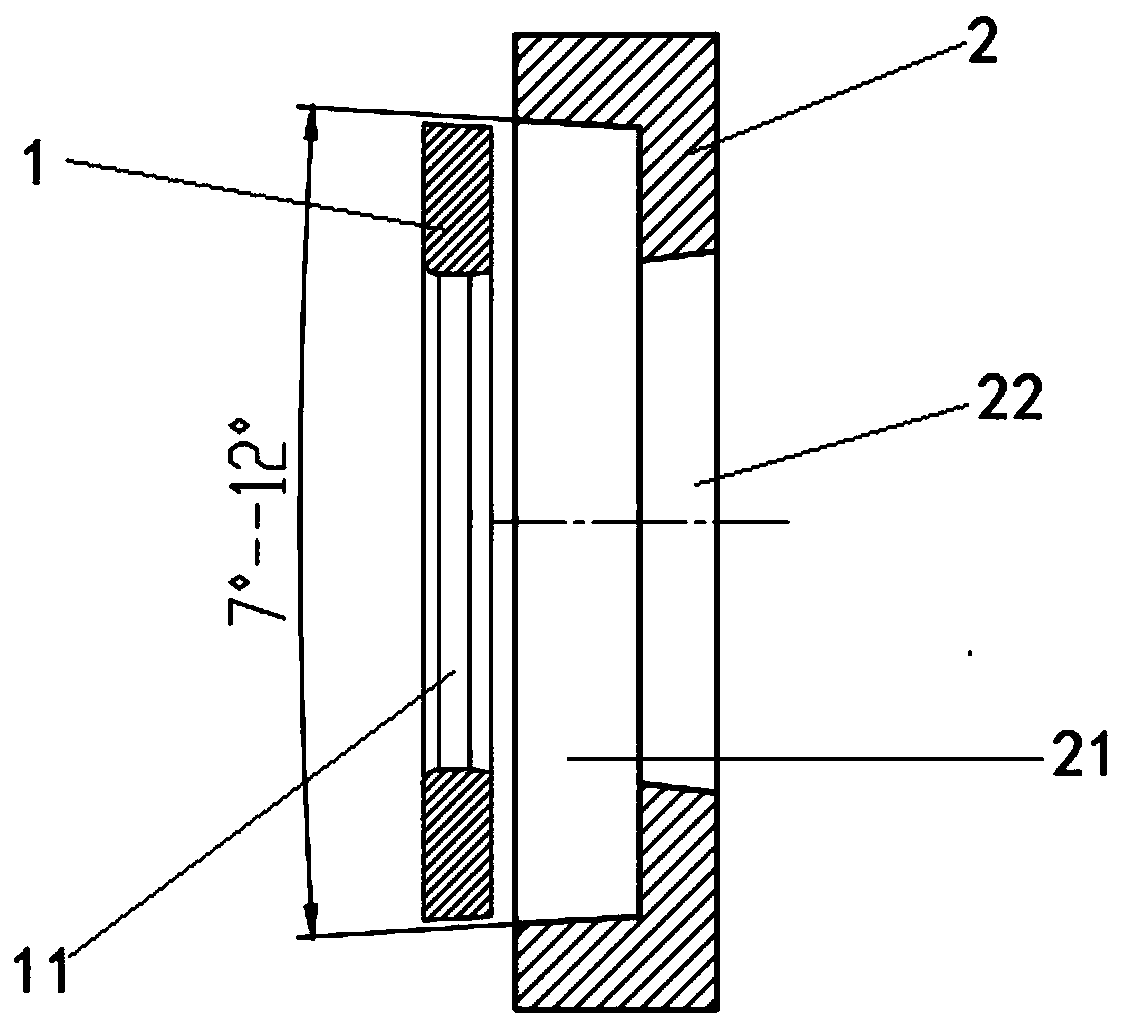

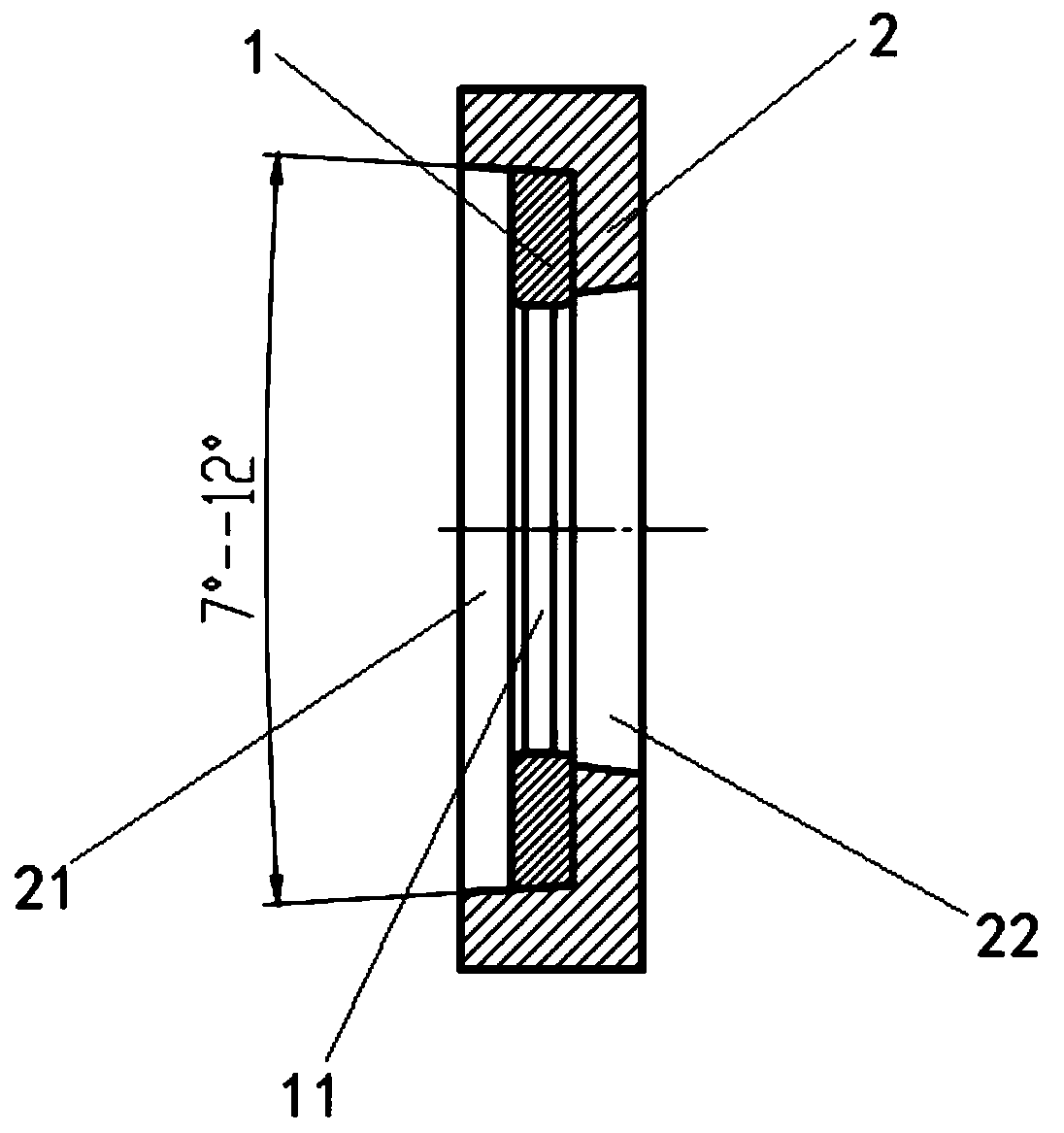

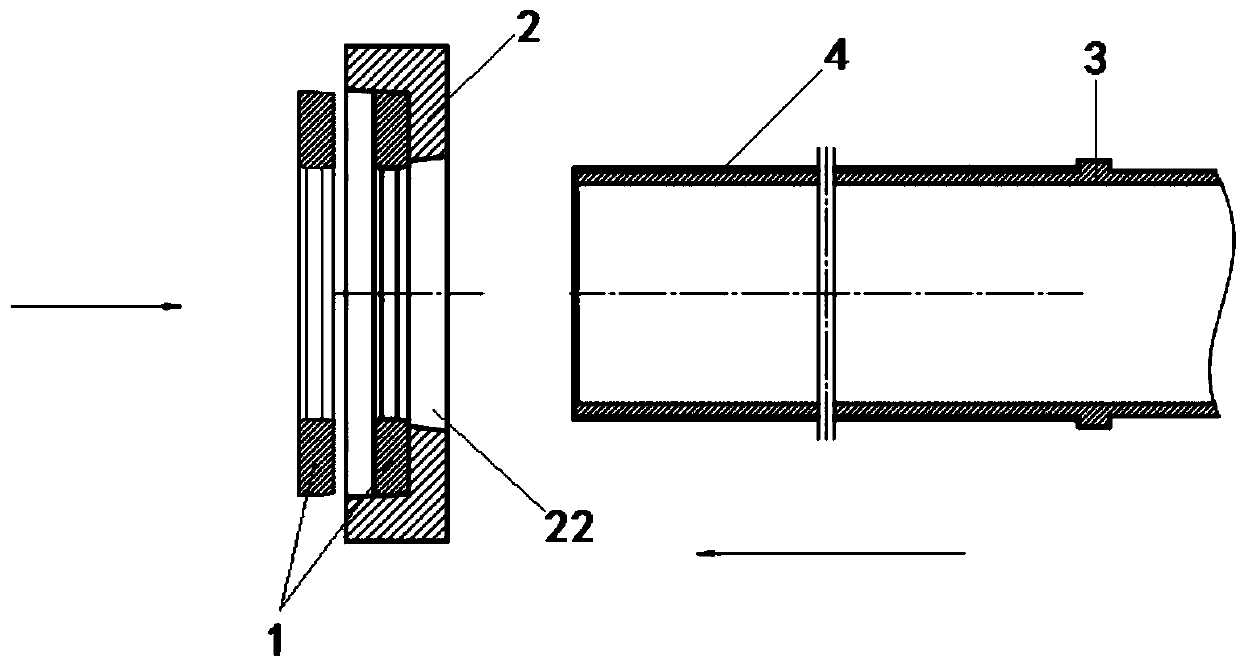

[0033] Such as figure 1 and 2 As shown, the combined cold drawing die includes an inner mold 1 and an outer mold 2, one end of the outer mold 2 is provided with a conical notch 21, and the other end of the outer mold 2 is provided with a round hole communicated with the conical notch 21. 22. The round hole 22 processed by the outer mold is located at the small end of the conical notch 21, and the diameter of the small end of the notch 21 is larger than the diameter of the round hole 22 processed by the outer mold; the inner mold 1 is a conical inner mold, and the inner mold 1 The taper of the outer wall is the same as the taper of the inner wall of the truncated conical notch 21, and the diameter of the large end of the inner mold 1 is equal to the diameter of the large end of the conical notch 21, and the axial depth of the conical notch 21 is greater than that of the internal mold 1. Axial height; the inner mold 1 is provided with an inner hole 11 along the axial direction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com