Preparation method of sandwich-structured intelligent hydrogel material drag reduction surface

A hydrogel and sandwich technology, which is applied in the field of preparation of drag-reducing surfaces of intelligent hydrogel materials, can solve the problems of non-resistance to fluid shear force, increased volume, poor durability, etc., and achieve the best drag-reducing effect, reduce Effect of shear stress and reduction of wall frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

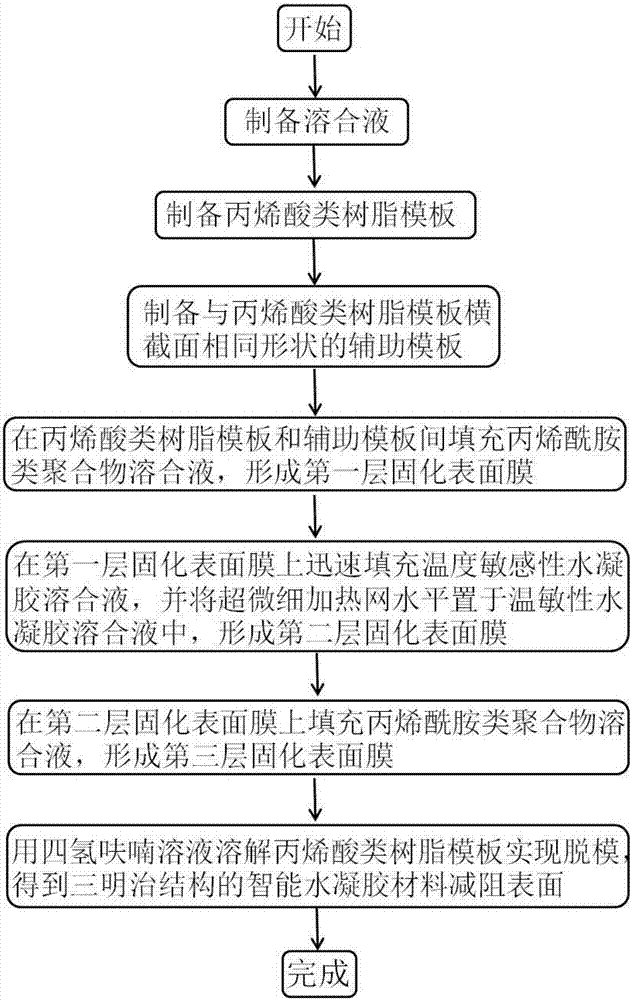

[0030] The method of the present invention is as figure 1 As shown, the specific steps are as follows:

[0031] 1.1 Take 90% of the acrylic resin solution and 10% of the ultrafine aluminum oxide according to the volume percentage of each component, and fuse them to obtain a toughened acrylic resin fusion solution;

[0032] 1.2 According to the volume percentage of each component, take 90% of acrylamide polymer, 5% of N,N-methylenebisacrylamide crosslinking agent, and 5% of aminosilane curing agent, stir evenly with a stirrer, and pass through at room temperature. Deoxygenate with nitrogen for 30 minutes to prepare acrylamide polymer solution;

[0033] 1.3 According to the volume percentage of each component, take 90% of temperature-sensitive hydrogel solution, 5% of N,N-methylenebisacrylamide crosslinking agent, and 5% of tetramethylethanedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com