Water mist dust falling and material guide device and dust falling method

A material guide device and water mist technology, which is applied in the field of coal conveying system, can solve the problems of health threats to workers, affect labor productivity, and consume a lot of time, and achieve the effects of protecting health, preventing dust spillage, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

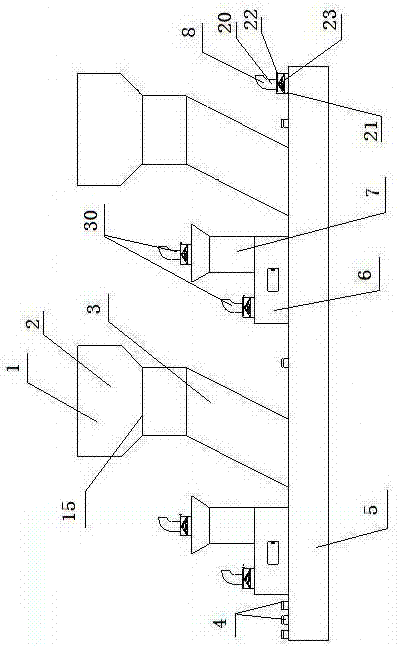

Embodiment 1

[0022] A water mist dust reduction material guide device, which consists of: a material guide trough 5, a plurality of coal falling devices 1 are installed on the material guide trough, and a decompression device is installed on the left end of each of the described coal falling devices 15. Electrostatic sealing curtains 4 are installed between and at both ends of the plurality of coal falling devices, and a water mist dust collector 8 is installed at the right end of the guide chute. The decompression device is made up of a primary decompression box 6, a secondary decompression box 7 and two decompression box water mist dust collectors 30, and the secondary decompression box is installed in the primary decompression box Above, the two decompression box water mist dust collectors are respectively installed on the first-stage decompression box and the second-stage decompression box.

Embodiment 2

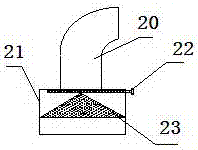

[0024] According to the water mist dust suppression material guide device described in embodiment 1, both the water mist dust suppressor and the decompression box water mist dust suppressor include a dust suppression box 21, and the dust suppression box is installed sequentially from top to bottom Spray nozzle 22, conical sieve plate 23 are arranged, and dust outlet pipe 20 is installed on the upper end of described dust suppression box.

Embodiment 3

[0026] According to the water mist dust reduction material guide device described in embodiment 1 or 2, the described coal falling device is composed of a coal falling hopper 2 and a coal falling pipe 3, and the described coal falling pipe is arranged at the lower end of the described coal falling hopper .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com