Adjustable universal wind grating for glass toughening furnace

A glass tempering and adjustable technology, applied in glass tempering, glass production, glass manufacturing equipment, etc., can solve the problems of large area multiplied by the length of the air grille, occupying normal production time, taking up a large production time, etc., to achieve automation High degree, effective use of wind energy, and the effect of reducing the cost of tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

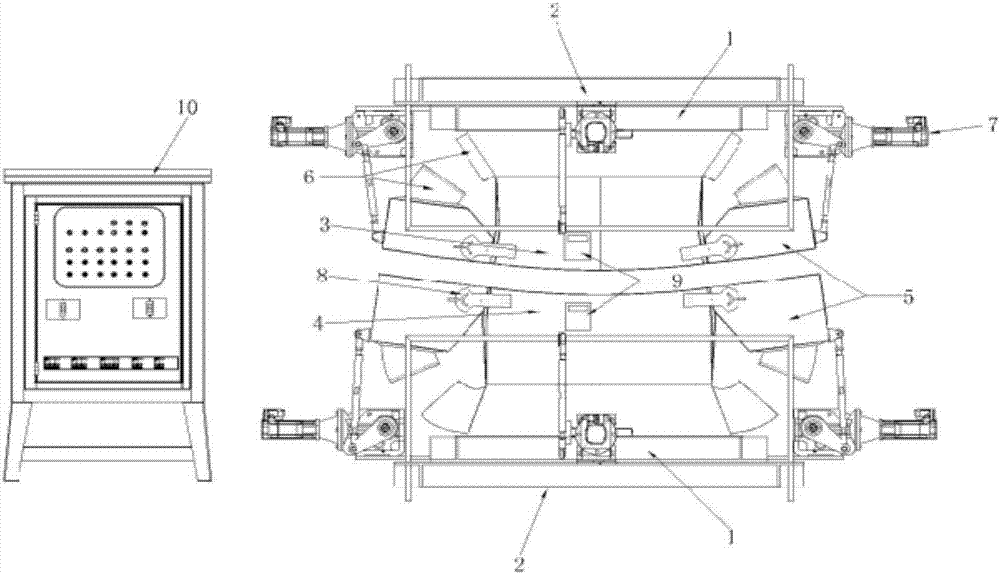

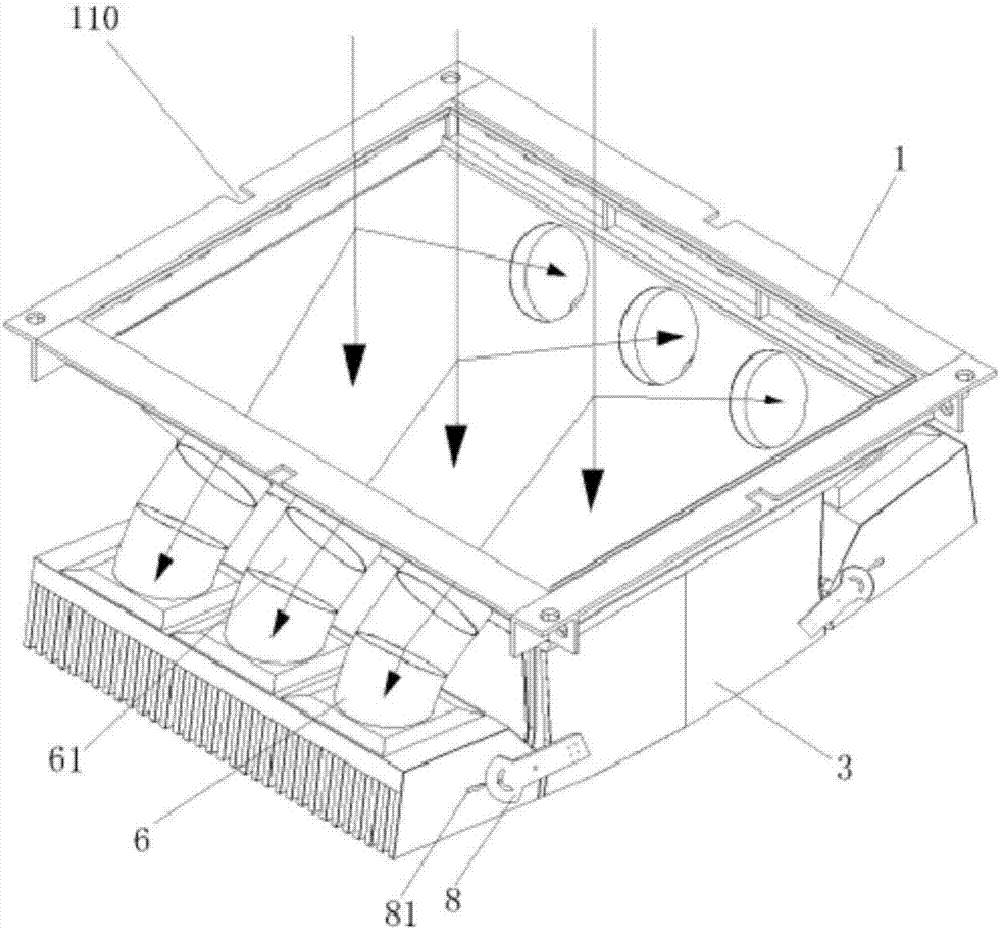

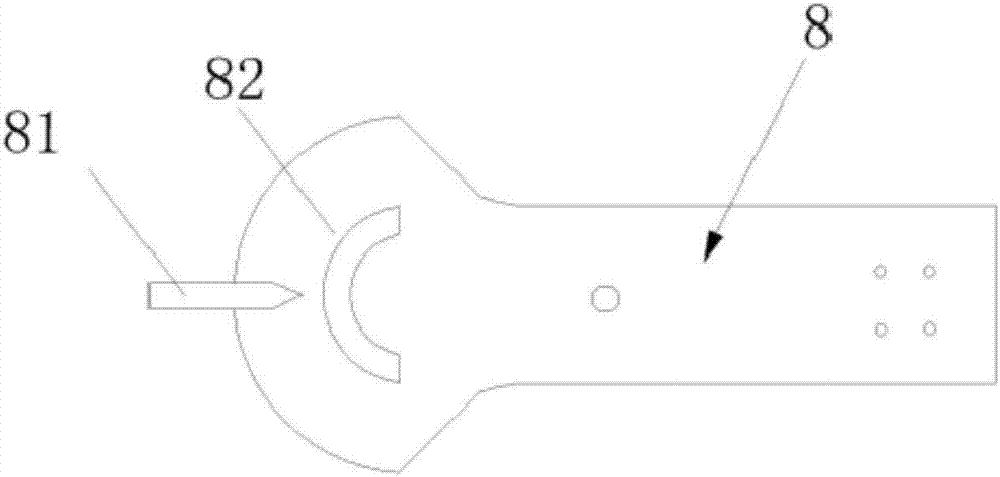

[0034] Such as figure 1 and figure 2 As shown, an adjustable universal air grid for glass tempering furnace includes an air grid fixing frame 1, and the air grid fixing frame 1 is a rectangular frame welded by 4 stainless steel angle steels. The middle of each angle steel has a 20mm×20mm The square groove of the upper wind grid body 3 and the lower wind grid body 4 are fixed on the wind grid fixing frame 1, and the side wing wind grids 5 connected by the connecting plate 8 are arranged on both sides of the upper wind grid body 3 and the lower wind grid body 4. The swing device 7 that drives the rotation of the side air grille 5 is arranged on the air grille fixing frame 1; figure 2 Middle arrow represents the conduction direction of wind) place is all provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com