Sulfoaluminate cement composite early strength agent and early strength sulfoaluminate cement

A technology of sulfoaluminate cement and composite early strength agent, which is applied in the field of sulfoaluminate cement composite early strength agent and early strength sulfoaluminate cement, can solve problems such as failure to meet early strength requirements, strength decline, etc. No reduction in later strength, improved workability, effect of high hourly strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of sulphoaluminate cement composite early strength agent that an embodiment of the present invention proposes, in parts by weight, it comprises:

[0048] Calcium hydroxide: 0.15 parts;

[0049] Ferrous sulfate: 3 parts;

[0050] Boric acid: 0.05 parts.

[0051] Another embodiment of the present invention provides an early-strength sulphoaluminate cement, which includes sulphoaluminate cement and the composite early-strength agent for sulphoaluminate cement in Example 1.

[0052] Described early-strength sulphoaluminate cement, by weight, it comprises:

[0053] Sulphoaluminate cement: 100 parts;

[0054] Calcium hydroxide: 0.15 parts;

[0055] Ferrous sulfate: 3 parts;

[0056] Boric acid: 0.05 parts.

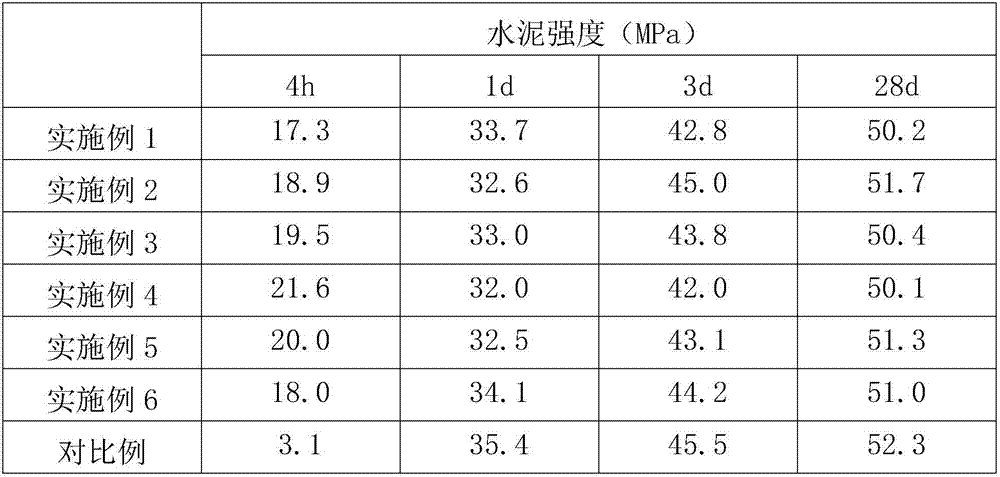

[0057] The cement strength of early strength sulfoaluminate cement is shown in Table 1.

Embodiment 2

[0059] A kind of sulphoaluminate cement composite early strength agent that an embodiment of the present invention proposes, in parts by weight, it comprises:

[0060] Calcium hydroxide: 0.15 parts;

[0061] Iron sulfate: 2.5 parts;

[0062] Borax: 0.075 parts.

[0063] Another embodiment of the present invention provides an early-strength sulphoaluminate cement, which includes sulphoaluminate cement and the composite early-strength agent for sulphoaluminate cement in Example 2.

[0064] Described early-strength sulphoaluminate cement, by weight, it comprises:

[0065] Sulphoaluminate cement: 100 parts;

[0066] Calcium hydroxide: 0.15 parts;

[0067] Iron sulfate: 2.5 parts;

[0068] Borax: 0.075 parts.

[0069] The cement strength of early strength sulfoaluminate cement is shown in Table 1.

Embodiment 3

[0071] A kind of sulphoaluminate cement composite early strength agent that an embodiment of the present invention proposes, in parts by weight, it comprises:

[0072] Calcium hydroxide: 0.25 parts;

[0073] Ferrous sulfate: 2 parts;

[0074] Citric acid: 0.05 parts.

[0075] Another embodiment of the present invention provides an early-strength sulphoaluminate cement, which includes sulphoaluminate cement and the composite early-strength agent for sulphoaluminate cement in Example 3.

[0076] Described early-strength sulphoaluminate cement, by weight, it comprises:

[0077] Sulphoaluminate cement: 100 parts;

[0078] Calcium hydroxide: 0.25 parts;

[0079] Ferrous sulfate: 2 parts;

[0080] Citric acid: 0.05 parts.

[0081] The cement strength of early strength sulfoaluminate cement is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com