Thermal-insulation aerogel masonry mortar and preparation method thereof

A masonry mortar and airgel technology, which is applied in ceramic products, other household utensils, applications, etc., can solve the problem of airgel powder falling off, the decrease of mechanical properties of masonry mortar, and the density difference between airgel powder and concrete major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of airgel thermal insulation masonry mortar, comprising the following steps:

[0023] (1) Airgel powder modification;

[0024] (2) The airgel powder obtained in step (1) is dry mixed with the gelling material, and then wet mixed with water.

[0025] In addition, the step (2) of the present invention can also be to dry mix the gelling material, then add water to wet mix, and add the airgel powder obtained in step (1) during wet mixing.

[0026] In this way, the preparation method of the airgel heat-insulating masonry mortar of the present invention has the advantages of simple process, short process cycle, excellent thermal insulation performance, waste utilization and environmental protection, and is very suitable for industrial production.

[0027] One or more of propyltrimethoxysilane, γ-methacryloxypropyltrimethoxysilane, N-(β-aminoethyl)-γ-aminopropyltriethoxysilane.

[0028] In this way, due to the existing airgel preparation method, the prec...

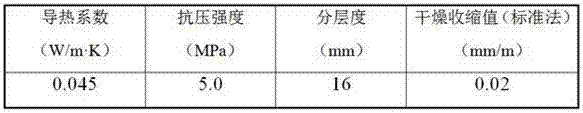

Embodiment 1

[0040] SiO was prepared using the following steps 2 Airgel thermal insulation masonry mortar:

[0041] (1) Detection of SiO to be treated using a contact angle meter 2 The contact angle between the surface of the airgel powder and water, the test result is 55°, and then SiO with a particle size of 56 μm 2 The airgel powder is placed in a vacuum heating furnace, and the weighed hexamethyldisilazane is placed in a vacuum heating furnace with a container, heated and vaporized, and hydrophobically modified for 1.5 hours to obtain hydrophobic SiO 2 Airgel powder, detection of hydrophobic SiO by contact angle meter 2 The contact angle between the surface of the airgel powder and water is 147°;

[0042] (2) At room temperature, weigh ethanol, n-hexane and deionized water at a mass ratio of 1:1:100, mix them evenly, and prepare a surface hydrophilic modification solution;

[0043] (3) According to hydrophobic SiO 2 The volume ratio of the airgel powder and the surface hydrophilic...

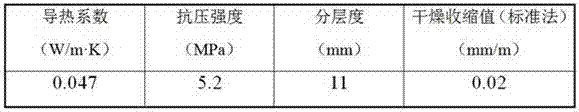

Embodiment 2

[0049] SiO was prepared using the following steps 2 Airgel thermal insulation masonry mortar:

[0050] (1) Detection of SiO to be treated using a contact angle meter 2 The contact angle between the surface of the airgel powder and water, the test result is 45°, and then SiO with a particle size of 0.1mm 2 The airgel powder is placed in a vacuum heating furnace, and the weighed trimethylchlorosilane is placed in a vacuum heating furnace with a container, heated and vaporized, and hydrophobically modified for 1.5 hours to obtain hydrophobic SiO 2 Airgel powder, detection of hydrophobic SiO by contact angle meter 2 The contact angle between the surface of the airgel powder and water is 146°;

[0051] (2) At room temperature, weigh fatty alcohol polyoxyethylene ether ammonium sulfate, n-hexane, acetone and deionized water according to the mass ratio of 1:0.4:0.4:130, mix them evenly, and prepare a surface hydrophilic modification solution;

[0052] (3) According to hydrophobic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com