Technology of preparing 3,4-dihydroxybenzoic acid by using longan shells

A technology of protocatechuic acid and longan shell, which is applied in the field of preparing protocatechuic acid by using longan shell, can solve the problems of resource waste, environmental pollution, discarding and the like, and achieve the effect of reducing environmental pollution and resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

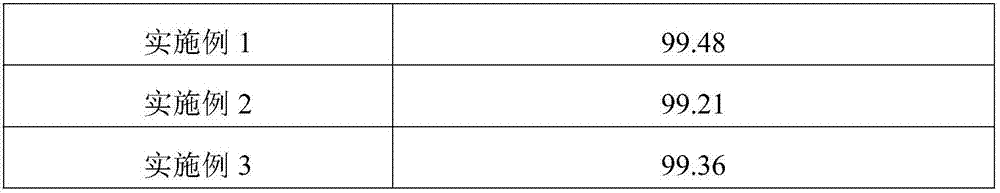

Embodiment 1

[0035] A kind of technology that utilizes longan shell to prepare protocatechuic acid comprises the following steps:

[0036] S1: crushing longan shells and passing through a 60-mesh sieve to obtain longan shell powder;

[0037] S2: Weigh 85 parts of the longan shell powder prepared in step S1, use low-temperature liquid nitrogen beating technology, and beat at a temperature of -12°C to obtain a longan shell slurry, and mix the longan shell slurry with 14 parts of 1-allyl- 3-Methylimidazole chloride and 25 parts of 1-ethyl-3-methylimidazole acetate were mixed evenly, put into an extraction bottle, and extracted for 1.5h under the conditions of ultrasonic power of 400W and temperature of 86°C to obtain Extraction solution, adjust the pH value of the extraction solution to 4.6, control the temperature at 50°C, decolorize and remove impurities by activated carbon for 1.3h, and obtain a decolorization solution after filtration;

[0038] S3: Concentrate and dry the primary decolor...

Embodiment 2

[0043] A kind of technology that utilizes longan shell to prepare protocatechuic acid comprises the following steps:

[0044] S1: crushing longan shells and passing through a 30-mesh sieve to obtain longan shell powder;

[0045] S2: Weigh 43 parts of longan shell powder prepared in step S1, use low-temperature liquid nitrogen beating technology, and beat at a temperature of -10°C to obtain longan shell slurry, mix longan shell slurry with 7 parts of 1-allyl- 3-Methylimidazole chloride and 15 parts of 1-ethyl-3-methylimidazole acetate were mixed evenly, put into an extraction bottle, and extracted for 1.6h at an ultrasonic power of 300W and a temperature of 76°C to obtain Extraction solution, adjust the pH value of the extraction solution to 4.2, control the temperature at 46°C, decolorize and remove impurities by activated carbon for 1.6h, and obtain a decolorization solution after filtration;

[0046] S3: Concentrate and dry the primary decolorization solution obtained in st...

Embodiment 3

[0051] A kind of technology that utilizes longan shell to prepare protocatechuic acid comprises the following steps:

[0052] S1: crushing the longan shell and passing through an 80-mesh sieve to obtain longan shell powder;

[0053] S2: Weigh 123 parts of longan shell powder prepared in step S1, use low-temperature liquid nitrogen beating technology, and beat at a temperature of -15°C to obtain longan shell slurry, mix longan shell slurry with 20 parts of 1-allyl- 3-Methylimidazole chloride and 30 parts of 1-ethyl-3-methylimidazole acetate were mixed evenly, put into an extraction bottle, and extracted for 1.2h at an ultrasonic power of 450W and a temperature of 92°C to obtain Extraction solution, adjust the pH value of the extraction solution to 5.3, control the temperature at 52°C, decolorize and remove impurities by activated carbon for 0.9h, and obtain a decolorization solution after filtration;

[0054] S3: Concentrate and dry the primary decolorization solution obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com