Crude oil anti-corrosion treatment equipment based on electronic control

An electronic control and anti-corrosion treatment technology, applied in the direction of electro/magnetic refining and centrifugal force refining, etc., can solve the problems of low desalination and dehydration rate, increased desalination cost, and poor desalination effect of a single desalination tank, so as to improve the desalination rate, High use value, the effect of improving the single desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

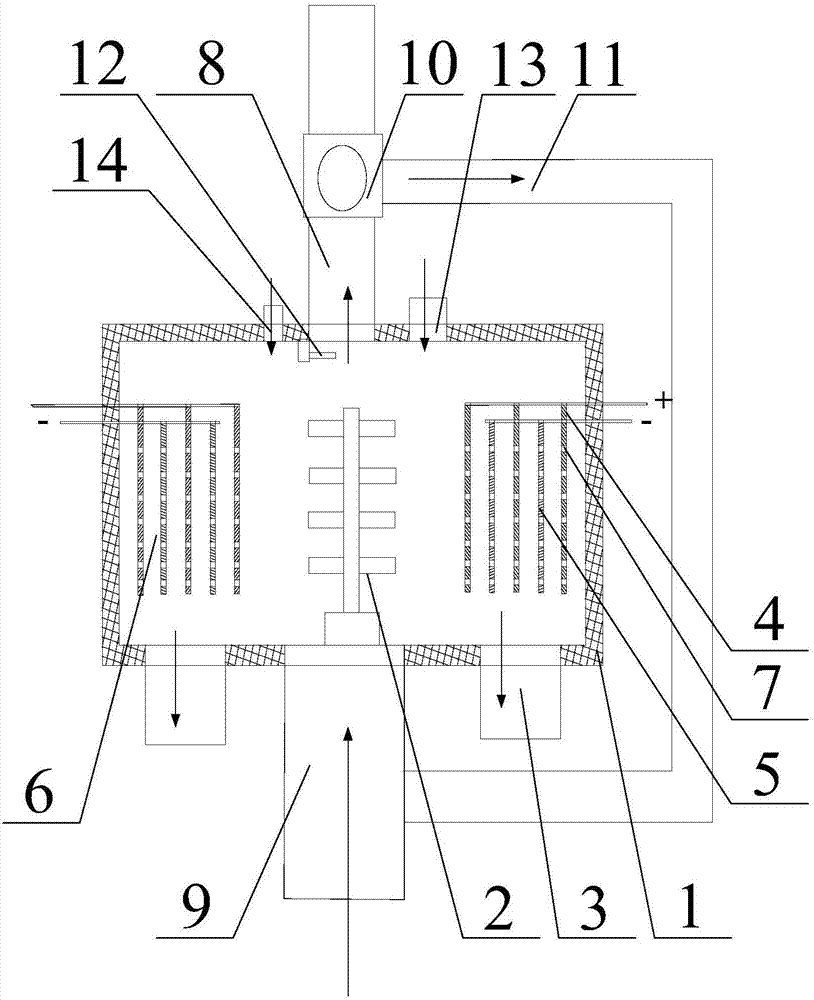

[0027] Such as figure 1 As shown, the present invention is based on electronically controlled crude oil anti-corrosion treatment equipment, including a desalting tank 1. Two high-voltage electric field mechanisms are arranged inside the desalting tank 1, and the two high-voltage electric field mechanisms are symmetrical about the center line of the desalting tank 1. A centrifugal mixing device 2 is also arranged between the two high-voltage electric field mechanisms. The central axis of the centrifugal mixing device 2 coincides with the center line of the desalination tank 1. Two sewage outlets 3 are opened at the bottom of the desalination tank 1. The sewage outlets 3 corresponds to the high-voltage electric field mechanism and is located directly below the high-voltage electric field mechanism. The high-voltage electric field mechanism includes several positive electrode plates 4 and negative electrode plates 5, and the positive electrode plates 4 and negative electrode plate...

Embodiment 2

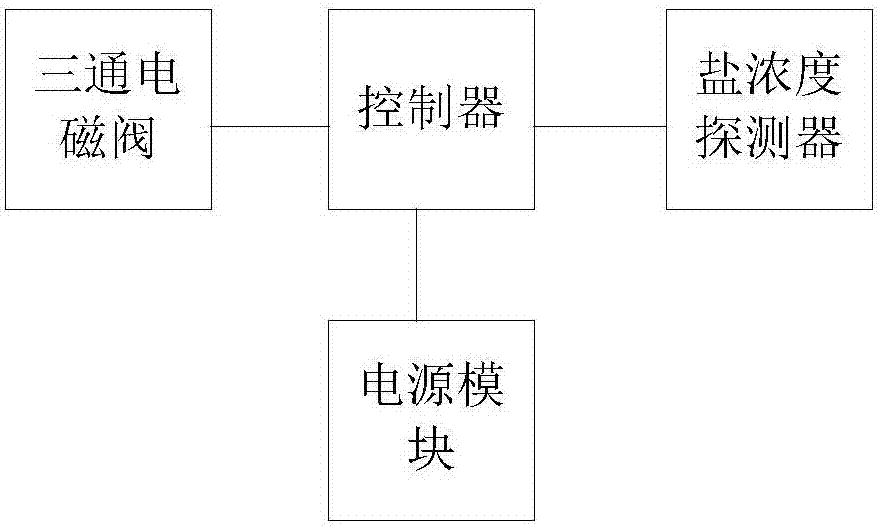

[0030] Such as Figure 1~2 As shown, the present invention is based on electronically controlled crude oil anti-corrosion treatment equipment. On the basis of Embodiment 1, the top of the desalination tank 1 is provided with an oil outlet pipeline 8, and the bottom is provided with an oil inlet pipeline 9. The end is also provided with a three-way solenoid valve 10, one end of the three-way solenoid valve 10 is connected with the oil inlet pipeline 9 through the return pipeline 11; Detector 12, described salt concentration detector and three-way solenoid valve 10 are all connected with a controller, wherein:

[0031] Salt concentration detector 12: collect the salt concentration of the crude oil out of the tank at the connection port between the desalination tank 1 and the oil outlet pipeline 8, and transmit the salt concentration information to the controller;

[0032] Controller: receiving the salt concentration information sent by the salt concentration detector 12, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com