Preparation process of epoxy modified reverse osmosis membrane, reverse osmosis membrane and application of reverse osmosis membrane

A reverse osmosis membrane, epoxy modification technology, applied in osmosis/dialysis water/sewage treatment, reverse osmosis, semi-permeable membrane separation, etc. , The effect of low production cost and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

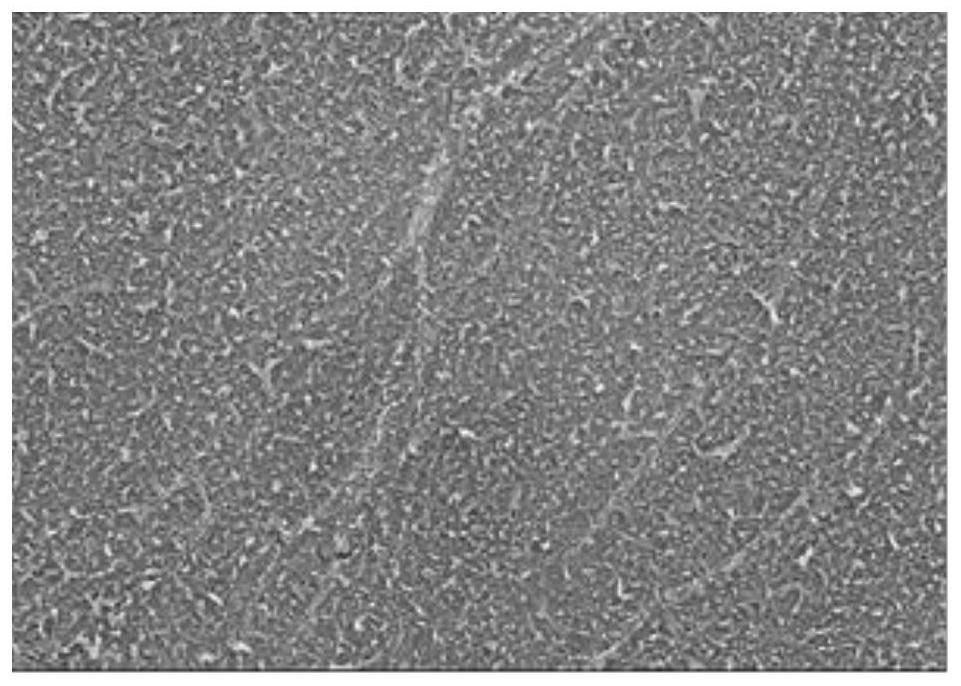

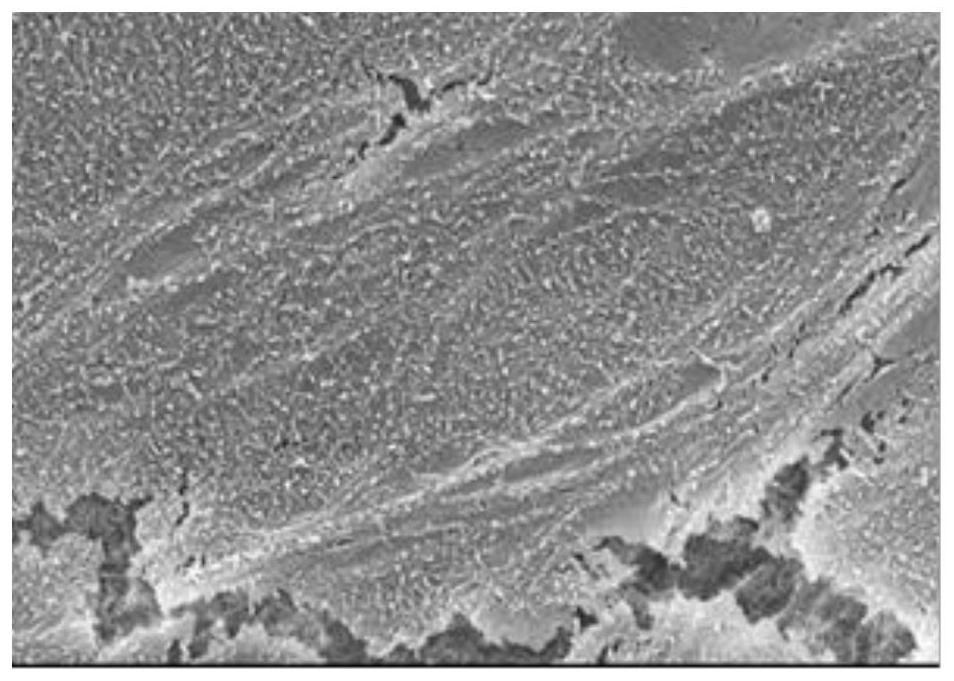

Image

Examples

Embodiment 1

[0053] The polyethylene film was subjected to corona treatment for 4 minutes at a voltage of 2.5 kv; the treated polyethylene film was immersed in 50% ethanol solution for 2 minutes. Subsequently, pure water was replaced for 2 minutes to obtain a polyethylene porous support layer A with a surface hydrophilized modification.

Embodiment 2

[0055] The polypropylene film was subjected to corona treatment for 4 minutes at a voltage of 2.5 kv; the treated polyethylene film was immersed in 50% ethanol solution for 2 minutes. Subsequently, the pure water was replaced for 2 minutes to obtain the surface hydrophilic modified polypropylene porous support layer B.

[0056] 【Example 1】

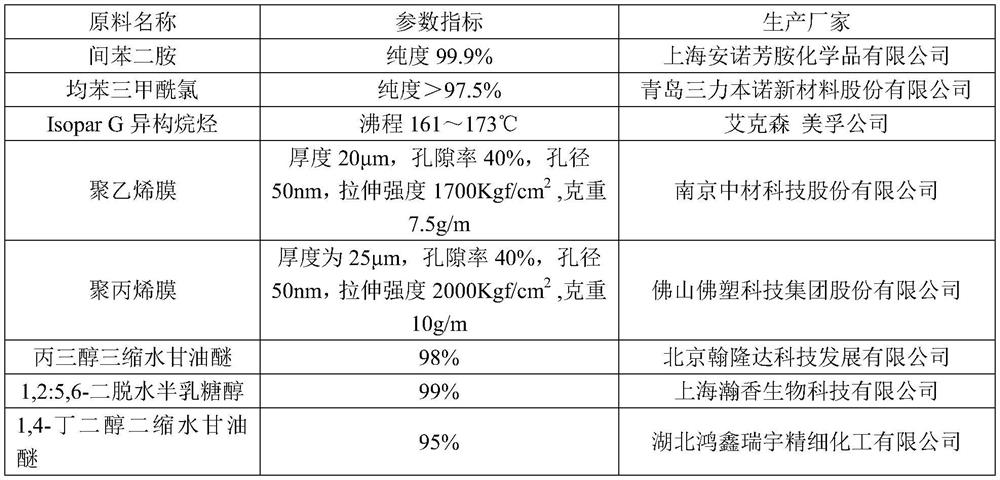

[0057] Refer to the raw material information in Table 2 and prepare epoxy modified reverse osmosis membrane according to the following method:

[0058] (1) Prepare an acetone solution of epoxy resin, apply it on the polyolefin porous support layer on one side, let it stand for 2 minutes, remove excess solution, wash and replace with pure water;

[0059] (2) The polyolefin porous support layer after coating is immersed in the aqueous phase solution of m-phenylenediamine, contacts 30s; Take out and remove unnecessary aqueous phase, then it is immersed in the organic phase solution of trimesoyl chloride (solvent is isopar G isoparaffin), co...

Embodiment 2-10

[0063] The epoxy-modified reverse osmosis membranes in Examples 2-10 were respectively prepared according to the method basically the same as that of Example 1, and the only difference was that the types and proportions of raw materials were added correspondingly with reference to Table 2.

[0064] Table 2, each embodiment raw material information

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com