Anti-oxidation and anti-biological fouling reverse osmosis membrane and its preparation method and application

A technology of anti-biological pollution and reverse osmosis membrane, applied in chemical instruments and methods, semi-permeable membrane separation, osmosis/dialysis water/sewage treatment, etc., can solve problems such as non-green materials, human body or environmental impact, and achieve anti-oxidation Good performance, strong anti-biological pollution performance, and the effect of improving tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

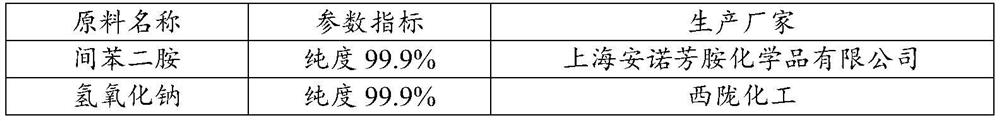

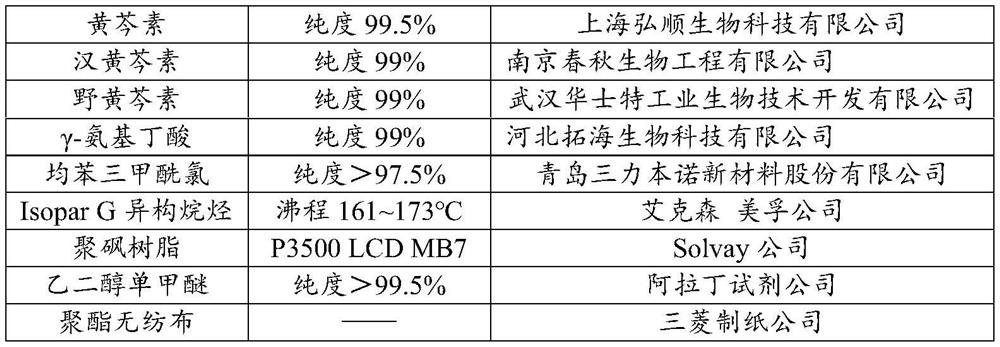

[0045] The preparation method of the anti-oxidation and anti-biological fouling reverse osmosis membrane of this embodiment comprises the following steps:

[0046] (1) The preparation method of the polysulfone support membrane is the same as that of Comparative Example 1.

[0047] (2) Preparation of the aromatic polyamide desalination layer: first prepare the aqueous phase A solution, wherein the content of each substance contained is: m-phenylenediamine 3.0wt%, sodium hydroxide 0.8wt%, baicalein 0.01wt%, γ -Aminobutyric acid 0.02wt%; then contact the aqueous phase A solution with the wet polysulfone support membrane for 30s; (The solvent is Isopar G isoparaffin) contact reaction for 30s, polyamide composite film is formed by interfacial polycondensation; polyamide composite film is drained vertically in hot air at 90°C for 5min, and then enters the temperature at 50°C and the concentration of 20.0wt % methanol aqueous solution and a citric acid aqueous solution with a temper...

Embodiment 2

[0049] The preparation method of the anti-oxidation and anti-biological fouling reverse osmosis membrane of this embodiment comprises the following steps:

[0050] (1) The preparation method of the polysulfone support membrane is the same as that of Comparative Example 1.

[0051] (2) Preparation of the aromatic polyamide desalination layer: the difference from the preparation method of the aromatic polyamide desalination layer in Example 1 is only that: 3.0 wt% of m-phenylenediamine and 0.8 wt% of sodium hydroxide in the aqueous phase A solution , baicalein 0.01wt%, γ-aminobutyric acid 0.02wt% were replaced by: m-phenylenediamine 3.0wt%, sodium hydroxide 0.8wt%, baicalein 0.02wt%, γ-aminobutyric acid 0.04wt%; The air temperature was 100° C., the heat treatment time was 10 min, and the rest of the experimental conditions and reaction steps were the same as the preparation method of the aromatic polyamide desalination layer in Example 1.

Embodiment 3

[0053] The preparation method of the anti-oxidation and anti-biological fouling reverse osmosis membrane of this embodiment comprises the following steps:

[0054] (1) The preparation method of the polysulfone support membrane is the same as that of Comparative Example 1.

[0055] (2) Preparation of the aromatic polyamide desalination layer: the difference from the preparation method of the aromatic polyamide desalination layer in Example 1 is only that: 3.0 wt% of m-phenylenediamine and 0.8 wt% of sodium hydroxide in the aqueous phase A solution , baicalein 0.01wt%, γ-aminobutyric acid 0.02wt% were replaced by: m-phenylenediamine 3.0wt%, sodium hydroxide 1.0wt%, baicalein 0.05wt%, γ-aminobutyric acid 0.1wt%; The air temperature was 120° C., the heat treatment time was 15 minutes, and the rest of the experimental conditions and reaction steps were the same as the preparation method of the aromatic polyamide desalination layer in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com